The rotary counter pressure cans filling machine is suitable for can filling and seaming. The technology of filling valve and control system adopt original technology of Germany, and seaming technology is from Switzerland.

This machine adopts advanced mechanical, electrical and pneumatic control technology, working stable, accurate filling level, attractive appearance, low O2 pickup, low Carbonated drinks lost and convenient maintenance.

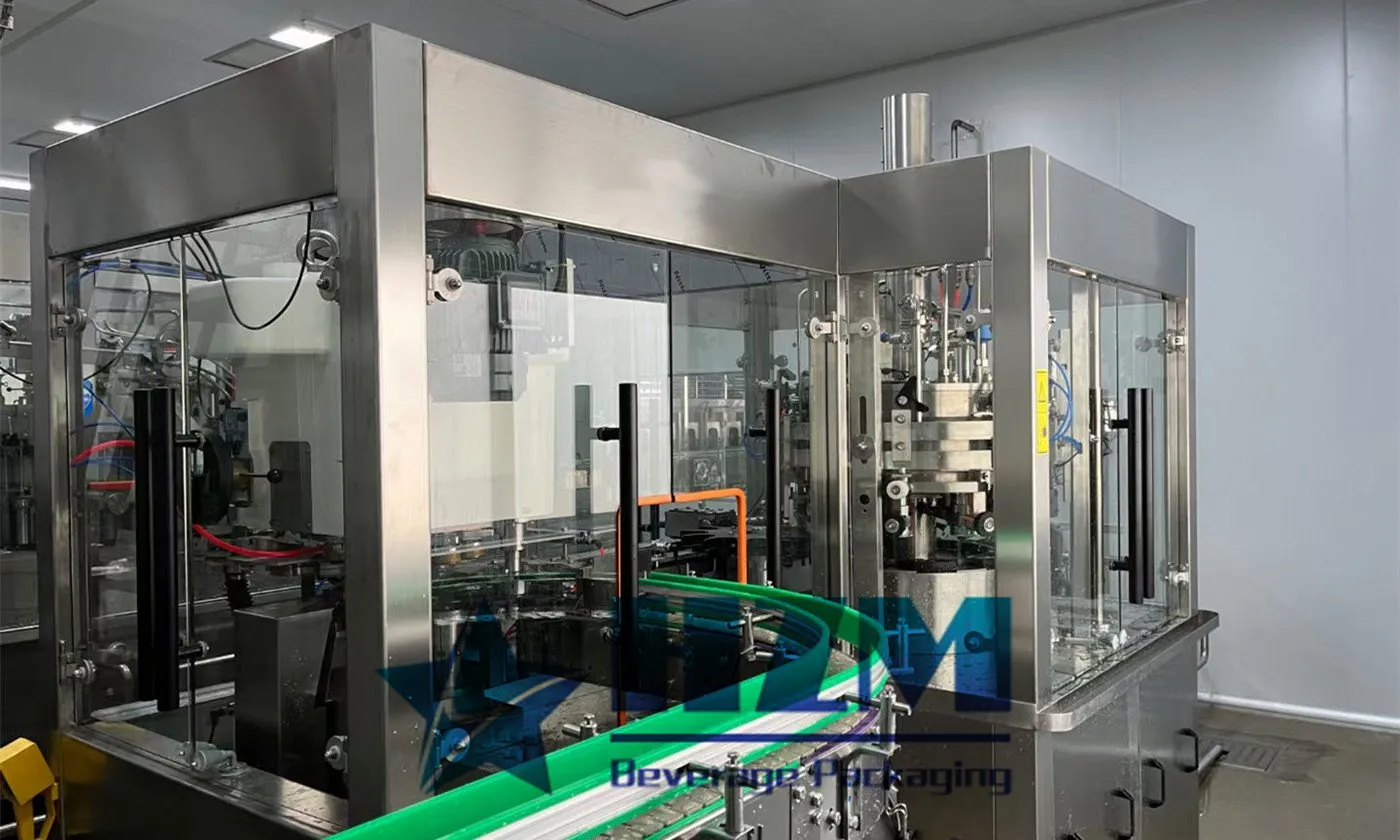

The cans filling machine has upper system, lower system, Carbonated drinks bowl inlet system, sending cap system, power output system and other components. External filling and seaming machine adopts all closed device to protect the surrounding clean.