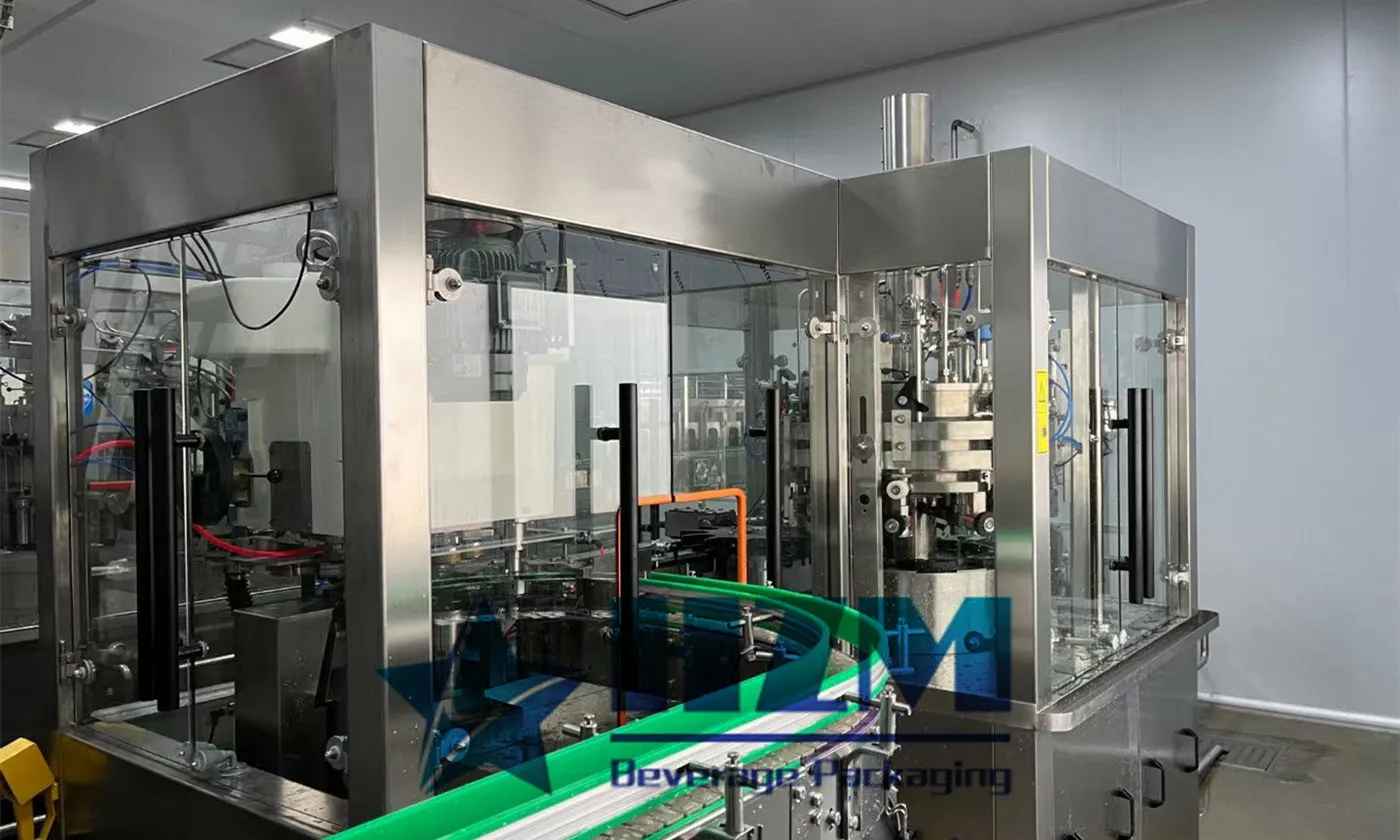

Craft beer can filling machine use rotary counter pressure filler-seamer system, it’s suitable for beer can filling and seaming. The technology of filling valve and control system adopt original technology of Germany, while seaming technology is that of Switzerland. The machine adopts advanced mechanical, electrical and pneumatic control technology.

Craft Beer Can Filling Machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

1. Beer can filling machine utilize the true counter-pressure-gravity filling technology to purge the can with fresh CO2 before filling, then fills the can gently by gravity, and then relieve the pressure in the can by Snifting CO2 from the can after filling. These functions help the beer can filling machine deliver low foam carbonated beverage, industry leading low DO pickup. 2. Can seamer is mono-blocked, continuous motion rotary seaming system. Not only does this mean that every can is seamed in the same amount of time after being filled, unlike inline fillers and seamers, but this also deliver more consistent seaming performance, smoother can transfer, better speed control and reduced O2 pick up. Heads Heads (Based on 330ml) (mm) (mm) (KW)Product Features

Product Configurations

Name

Supplier

Main Motor & Reducer

SEW-Germany

Rinsing Pump

CNP-China

Inverter

SIEMENS-Germany

PLC

SIEMENS-Germany

Touch Screen

SIEMENS-Germany

Contactor

SCHNEIDER-France

Hot Relay

SCHNEIDER-France

Photoelectric Switch

BANNER-USA

Pneumatic Components

FESTO-Germany

Product Parameters

Model

Filling

Seaming

Capacity

Filling Level Accuracy

Dimension

Power

CGS9/2

9

2

6000

±2

2855*1780*2350

5.0

CGS20/4

20

4

12000

±2

3153*1980*2350

5.0

CGS30/6

30

6

18000

±2

4800*2600*2350

7.2

CGS40/8

40

8

24000

±2

6500*2600*2350

11.0

CGS60/8

60

8

36000

±2

6500*2600*2350

11.0