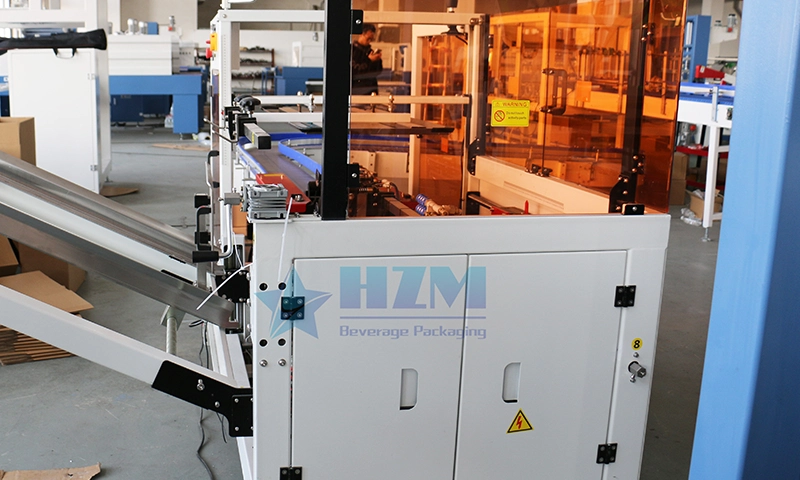

The carton packaging machine consists of three main components: the automatic carton forming machine, the automatic packaging machine, and the carton sealing machine. This setup ensures seamless integration for efficient carton handling, from forming to sealing.

Carton Package Machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

-

![Carton Package MachineIndustry application]() Mineral Water

Mineral Water

-

![Carton Package MachineIndustry application]() Juice

Juice

-

![Carton Package MachineIndustry application]() Carbonated Beverage

Carbonated Beverage

-

![Carton Package MachineIndustry application]() Canned Drink

Canned Drink

-

![Carton Package MachineIndustry application]() Wine

Wine

Basic performance of carton package machine

1. Mechanical parts chrome steel, stainless steel, aluminum and corrosion.

2. Main drive adopts adjustable speed reducer, variable speed, auto-correct feature.

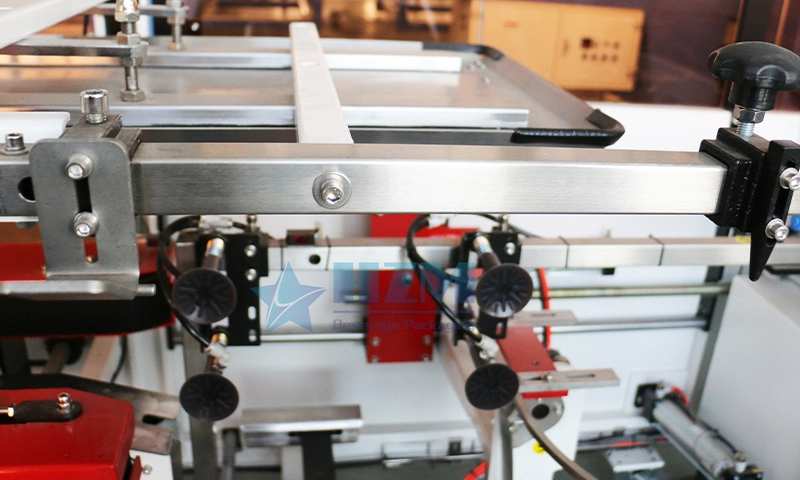

3. Bottle feeding conveyor chain plate made of a polymer material consisting of a low coefficient of friction, continuous feed bottles, lane guide.

4. For Product location for automatic speed adjustment and all the bottle detection.

5. The detection of inverted bottle and lack of bottle in the enter bottle place ,alarm for shortage of box.

Main configuration

| Brand | Product Category | Description |

|---|---|---|

| Schneider | Low Voltage Control System | Provides reliable low-voltage control solutions |

| AIRTAC | Pneumatic Components | Specialized supplier of pneumatic components |

| Autonics | Photoelectric Control System | High-precision photoelectric control equipment |

| SIEMENS | PLC and HMI | Offers advanced automation control systems |

Carton package machine main technical parameters

Work requirements

1. Products must enter the machine with relatively steady speed, feeding speed upstream products should be able to control, prevent excessive squeeze between products.

2. At the exit of the carton ,packaging products must be carefully removed in a timely manner, to ensure the normal packaging process