Features

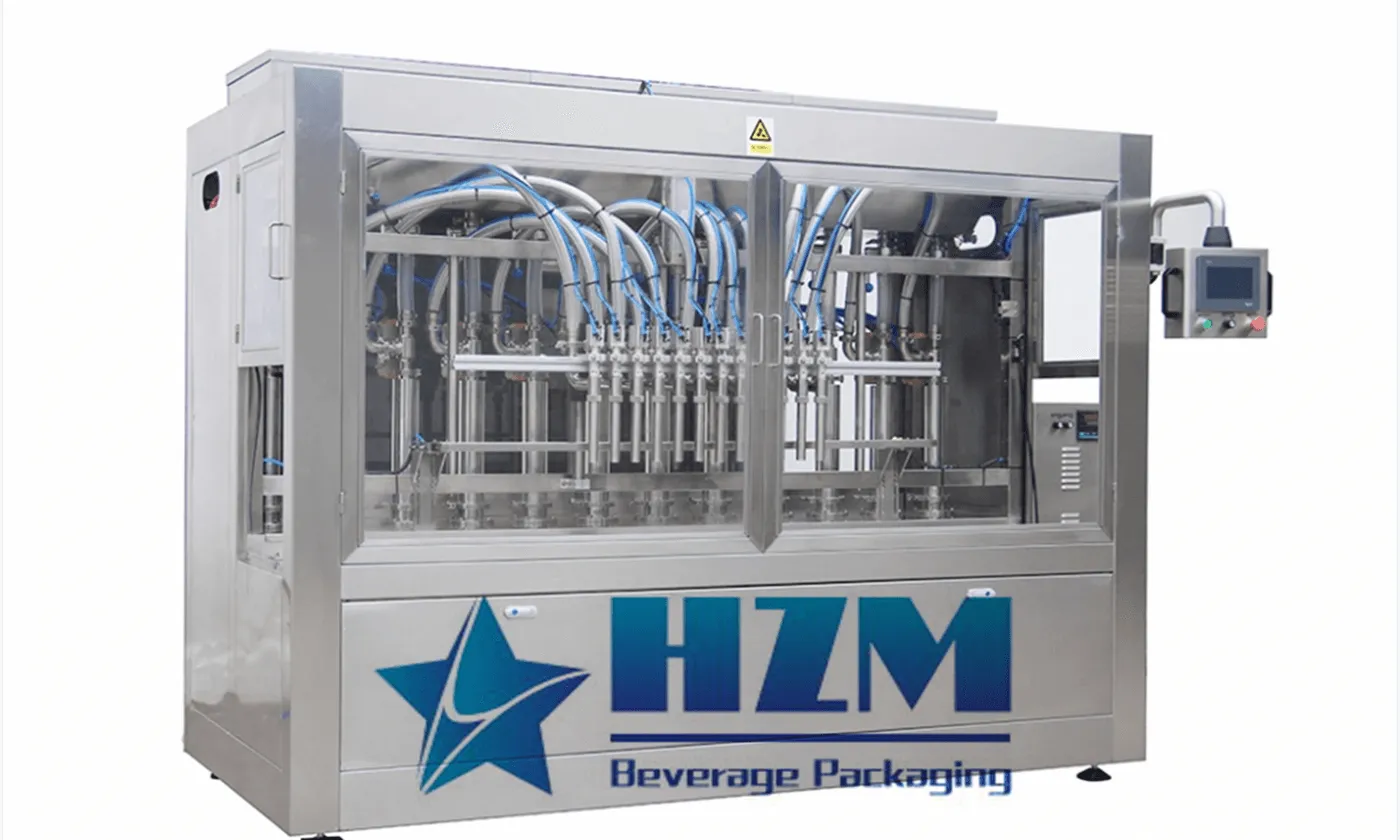

1. It is suitable for filling Lubricants Oil, vegetable oil, honey, jam, syrup, preparation, suspension agent, oil and various viscous materials in

daily chemical industry. Equipped with pneumatic diving nozzle,it has larger power to fill liquid.The diving nozzle can prevent the liquid from splashingas little as possible,improve filling accuracy.

2. It has high degree of automation and convenient adjustment. When changing specifications or revising measurement, it only needs to be adjusted on the display screen to meet the requirements.Quantitative filling, adjustment for one key.Fast interface easy to be dismantled easy to wash, no drip,diving filling.The internal adjustment of the machine is simple.Short adjustment time for replacing bottle shape.

3.Adopt servo control, piston filling form, PLC and man-machine control interface. With four groups of dose adjustment memory data,

The piston stroke is driven by servo motor, the stroke positioning is accurate, and the filling speed is set fast and slow.When

the filling is close to the mouth of the bottle, the speed pressure is reduced to prevent the liquid from spilling due to the

large impact.

| Automatic Linear Piston Pressured Type Liquid Filling Machine |

| Model |

HZM-6H |

HZM-8H |

HZM-12H |

HZM-16H |

HZM-20H |

| Filling nozzle |

6 |

8 |

12 |

16 |

20 |

| Dimension |

2000*1300*2350 |

2000*1300*2350 |

2800*1300*2350 |

2800*1300*2350 |

2800*1300*2350 |

| Power supply |

220/380V 50/60HZ, 2KW |

| Filling speed |

20-50 bottles/minute |

| Filling volume |

500-5000ml, 1L-10L, 2L-20L |

| Filling form |

Piston filling |

| Filling accuracy |

±1.0% |

| Air pressure |

0.6-0.8MPa |

Features:

1. Made by high quality 304 Stainless steel, it is durable

2.No bottle no fill.

3.Can control different filling speed on one dose.

4.Filling system is controlled by servo motor, it assure high filling accuracy.

5.Diving filling head is available according to different product(For option).

6.Air blow off filling nozzle is available for sticky product to avoid tail stringing on nozzle.

7.Product receive tray is available in case any leakage from filling nozzle(For option).

8.Can save up to 20 groups parameter on the PLC, convenient for operation.

9.No tooling needed to change over different size bottles.

10.Quick-install connecting parts , it is easy to disassemble and clear machine.