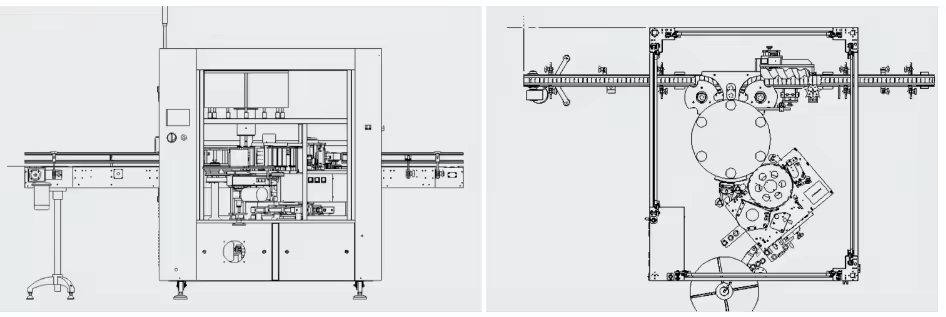

The mineral water bottle labeling machine uses self-adhesive roll label paper and employs a rolling method for labeling. It is equipped with automatic bottle feeding and collecting devices, allowing for the entire process of bottle placement, labeling, and collection to be completed in one go. Additionally, it can be equipped with a printer to synchronize label printing. The machine utilizes computer fiber optic control and synchronous tracking, with label dispensing controlled by a mutual induction stepper motor to ensure the label dispensing speed is synchronized with the bottle rolling speed, achieving efficient automation in packaging.

Automatic Water Bottle Labeling Machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

-

![Automatic Water Bottle Labeling MachineIndustry application]() Mineral Water

Mineral Water

-

![Automatic Water Bottle Labeling MachineIndustry application]() Juice

Juice

-

![Automatic Water Bottle Labeling MachineIndustry application]() Carbonated Beverage

Carbonated Beverage

-

![Automatic Water Bottle Labeling MachineIndustry application]() Canned Drink

Canned Drink

-

![Automatic Water Bottle Labeling MachineIndustry application]() Wine

Wine

Product number

| Model | Capacity (BPH) |

Labeling Accuracy (mm) |

Bottle Diameter (mm) |

Label Height (mm) |

Label Thickness (mm) |

Dimension (mm) |

| HG-8K | 8000 | ±1 | φ55- φ120 | 40-200 | 0.035-0.13 | 2250*2000*2050 |

| HG-12K | 12000 | ±1 | φ55- φ120 | 40-200 | 0.035-0.13 | 2250*2000*2050 |

| HG-15K | 15000 | ±1 | φ55- φ120 | 40-200 | 0.035-0.13 | 2250*2000*2050 |

| HG-18K | 18000 | ±1 | φ55- φ120 | 40-200 | 0.035-0.13 | 2250*2000*2050 |

| HG-24K | 24000 | ±1 | φ55- φ120 | 40-200 | 0.035-0.13 | 2250*2000*2050 |

Equipment attributes

| Parameter | Details |

| Applicable Industries | Mineral water, bottled drinking water, beverages |

| Showroom Location | Philippines, Algeria |

| Place of Origin | China |

| Weight | 2000 KG |

| Warranty | 1 Year |

| Key Selling Points | Easy to Operate |

| Machinery Test Report | Not Available |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Motor |

| Type | LABELING MACHINE |

| Condition | New |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Voltage | 110V-240V |

| Brand Name | HZM |

| Dimension (LWH) | 150015001000 mm |

| Machinery Capacity | 12000 BPH |

| Product name | BOPP hot glue Labeling Machine |

| Application | Water, Beverage, Food Industry |

| Label material | OPP, BOPP, PAPER (roll type) |

| Label length | 10 mm - 330 mm |

| Bottle/can diameter | 50-106 mm |

| Junction line error | +/- 1.5 mm |

| Suitable bottle | Round Bottle Glass |

| After Warranty Service | Field Maintenance |

| Control | Schneider |

| Glue | Hot melt glue |

Features of Automatic Water Bottle Labeling Machine

1. Adopt the overall vertical labeling mode,automatically label cutting, automatic labeling.

2. Microcomputer continuously variable control system, automatic detection in accordance with the feed, automatic adjustment of the production rate to maintain the labeling machine always in the best production rate.

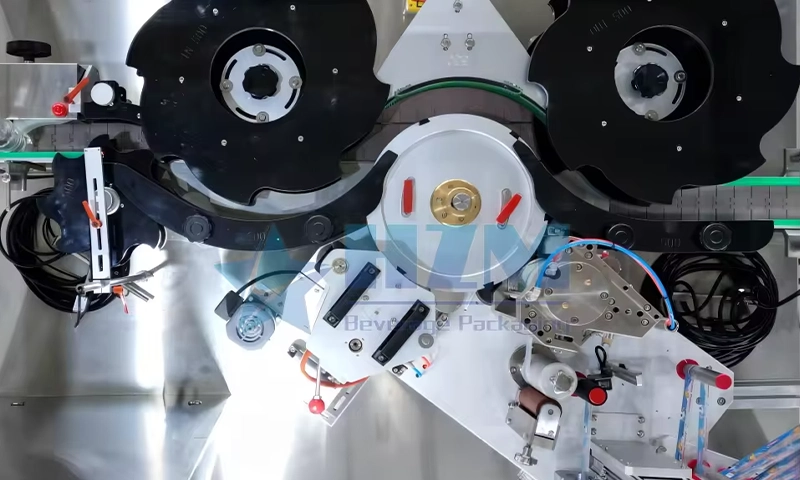

3. Applying the star-wheel feeding, to ensure not pour the bottle under high speed.

4. Host Controller working with the frequency three-phase motor to control transmission.

5. Label supply applying the servo motor synchronous tracking cutting, specially designed vacuum drum high-speed absorption, accurate and stable labeling.

6. Transmission mode applying the linked design, stability and precision under high-speed labeling.

7. Electronic automatic calibration label cutting system, cutting precision up to plus or minus 0.5 mm.

8. Linked design encountering abnormal or unusual torque, the safety devices can automatically and immediately shut down the machine.

9. Labeling position can be adjusted up and down.

10. Hot melt machine below the set temperature, the labeling action can not be started.

11. Without label, the machine automatically stops, and the alarm function starts.

12. Label is not affixed, the machine automatically stops, and the alarm function starts.automatically label cutting, automatic labeling.

Machine Details

1. The adjustment of label cutting blade is easy and simple.

2. Vacuum-grip cylinder is made of high hardness material,the additional old handler can reduce the frictions of labels and prevent static electriciy.

3. The change-over of shape pars can be finished with in 10 minutes

4. The position of cutting blade can be quickly and accurately adjusted by manual control cabinet

5. Vacuum-grip cylinder and cutting unit adopt special material which are wearproof and heat protection

6. The self-adjustmen knob can reset the I-MARK position while change he cutting length of labels