Product Features

1. 10% Output Increased

This machine has a mechanical structure design for high capacity. Servo controllers are used to elevate capacity for up to 10%. Coordinating with BECKHOFF system from Germany with effective control over co-motion of multiple shafts, redundant waiting time can be mitigated and goals of elevating capacity, stability, and safety can be achieved. Also remote CCTV is available to increase service quality, reduce productive costs, and improve effciency.

2. 20% Preform Weight Reduction

The all-electric linear design going with production of light-weight bottles can reduce 20% of bottle weight. The unique seal design is utilizing theory of pressure to maintain form of cap thread without distortion during blowing. The heating system, focusing on light-weight cap thread, is equipped with an independent cooling system for prevention of distortion caused by overheating of the neck fnish.

3. 30% Energy Saving

There is an air recycling device for re-use of high-pressure air within blow moulding machine for further conversion to be supplied to pneumatic tanks of each unit. Also we programmed the best permutation and combination of heating and reflection boxes which can save 30%~35% of energy waste compared with conventional linear PET Water Bottle Blowing Molding Machine.

4.The whole operation of bottle blowing machine with touch-screen operation, full display, production speed, shift production counting, fault type, etc. can be displayed on the screen. And automatic statistics failure time, fault type and other information, can achieve Man-machine dialogue.

5.Secondary blowing system specially designed to ensure the stability of the bottle molding quality, appropriate technology to meet customer standards.

6.The PET Water Bottle Blowing Molding Machine adopts four infrared heater thermostat control, digital automatic voltage regulator thermostat system.

7.The customers can set the appropriate temperature according to different preform is heated, and the other contains a variety of bottle-shaped blown required packages.

8. The Water Bottle Blowing Molding Machine is equipped with automatic processing machines and preform billet hoist.

Product Configurations

| Model |

HZ-CS6-38 |

HZ-CS8-38 |

HZ-CSS9-38 |

HZ-CSS12-38 |

| Clamping force(KG) |

60,000 |

72,000 |

60,000 |

72,000 |

| Clamping stroke(mm) |

130 |

130 |

130 |

130 |

| Stretching stroke(mm) |

320 |

350 |

320 |

240 |

| Bottom stroke(mm) |

50 |

50 |

50 |

50 |

| Cavity pitch(mm) |

120 |

120 |

80 |

80 |

| Number of cavity |

6 |

8 |

9 |

12 |

| Max volume(L) |

2 |

2 |

2 |

0.7 |

| Neck diameter range (mm) |

30 |

30 |

18-30 |

18-30 |

| Max container diameter(mm) |

105 |

105 |

105 |

70 |

| Max container height (mm) |

320 |

320 |

320 |

240 |

| Carriage unit(pcs) |

120 |

162 |

156 |

192 |

| Total power(KW) |

50 |

78 |

49 |

67 |

| Air consuming (ltr/min) |

8,000 |

9,100 |

10,500 |

14,000 |

Capacity for 0.5L

(BPH) |

12,000 |

16,000 |

18,000 |

21,600 |

| Dimension(mm) |

5,530*1,750*2,600 |

6,600*1,900*2,600 |

6,100*1,800*2,600 |

7,000*2,020*2,600 |

| Weight(KG) |

8,000 |

10,000 |

8,000 |

12,000 |

Water Bottle Blowing Molding Machine Featured components

Auto-loader

Auto-loader improves working efficiency, accurate transportation, reliable and durable, raw materials are completely free of moisture, pollution, foreign matter, and loss during feeding process. Realize transportation process of feeding process, avoid danger of high-altitude feeding, reduce labor intensity and increase production efficiency.

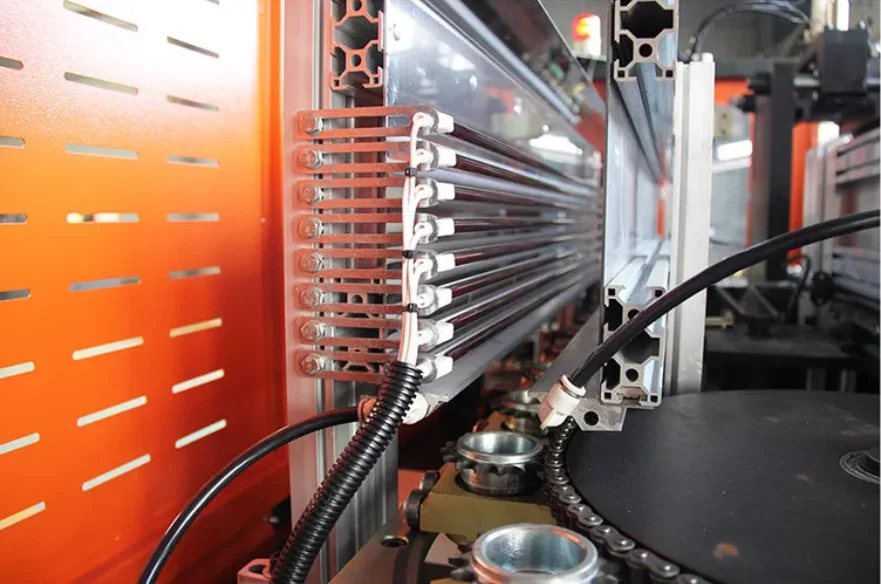

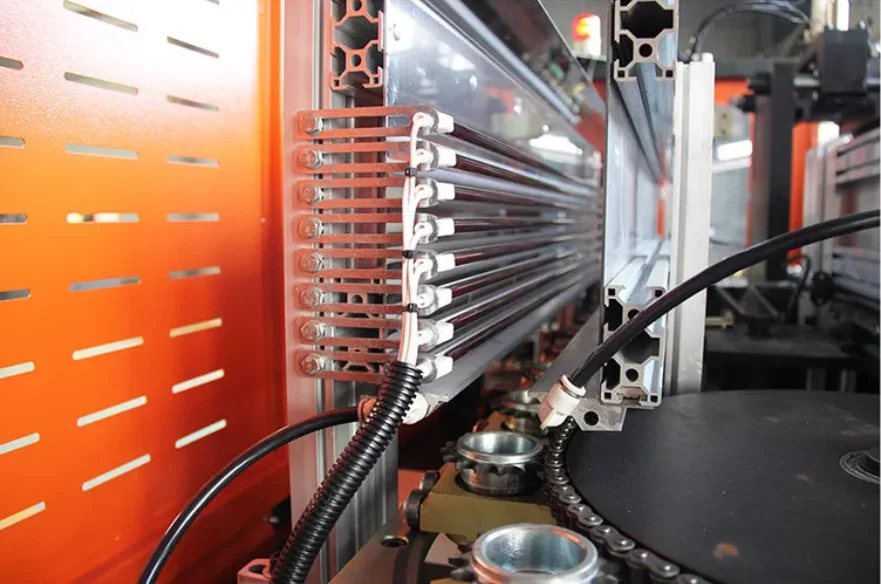

Infrared heating lamp

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable;Heating lamp, reflector width and height can be adjusted to suit preform heating of different structure, with automatic

temperature-removal device to ensure the constant temperature of oven.

Other attributes

| Parameter |

Value |

| Plastic Processed |

PET |

| Condition |

New |

| Application |

Bottle |

| Place of Origin |

Jiangsu, China |

| Weight (KG) |

8000 KG |

| Automation |

Automatic |

| Warranty |

2 years |

| Key Selling Points |

Energy saving |

| Applicable Industries |

Food & Beverage Factory |

| Machinery Test Report |

Provided |

| Video outgoing-inspection |

Provided |

| Warranty of core components |

2 years |

| Core Components |

Bearing, Motor, Gear, PLC, Engine |

| Max. Bottle Height (mm) |

320 mm |

| Bottle Volume (ml) |

2000 ml |

| Brand Name |

HZM |

| Year |

2022 |

| Voltage |

Customized |

| Dimension (LWH) |

According to model |

| High Pressure Valve Brand |

PARKER |

| Clamping Force (kN) |

According to model |

| Rotary Cylinder Brand |

FESTO |

| PLC Brand |

DELTA |

| Power (kW) |

According to model |

| Showroom Location |

Saudi Arabia, Russia, Thailand, Indonesia, Egypt, UAE, Kenya, Ethiopia |

| Application |

Plastic Bottle/PET Bottle/Diary Bottle/Beverage Bottle |

| Capacity |

4,000-21,600 BPH |

| Bottle Volume |

200ml-2000ml |

| Suitable For |

PET Bottle |

| Bottle Type |

Round/Square |

| After-sales Service Provided |

Free spare parts, Field installation, commission and training |

| PLC |

SIMENS (Germany) |

| Bottle Material |

PP, PE, PET, PVC |

| Heating Method |

Electric cycle heating |

| Power (W) |

48KW |