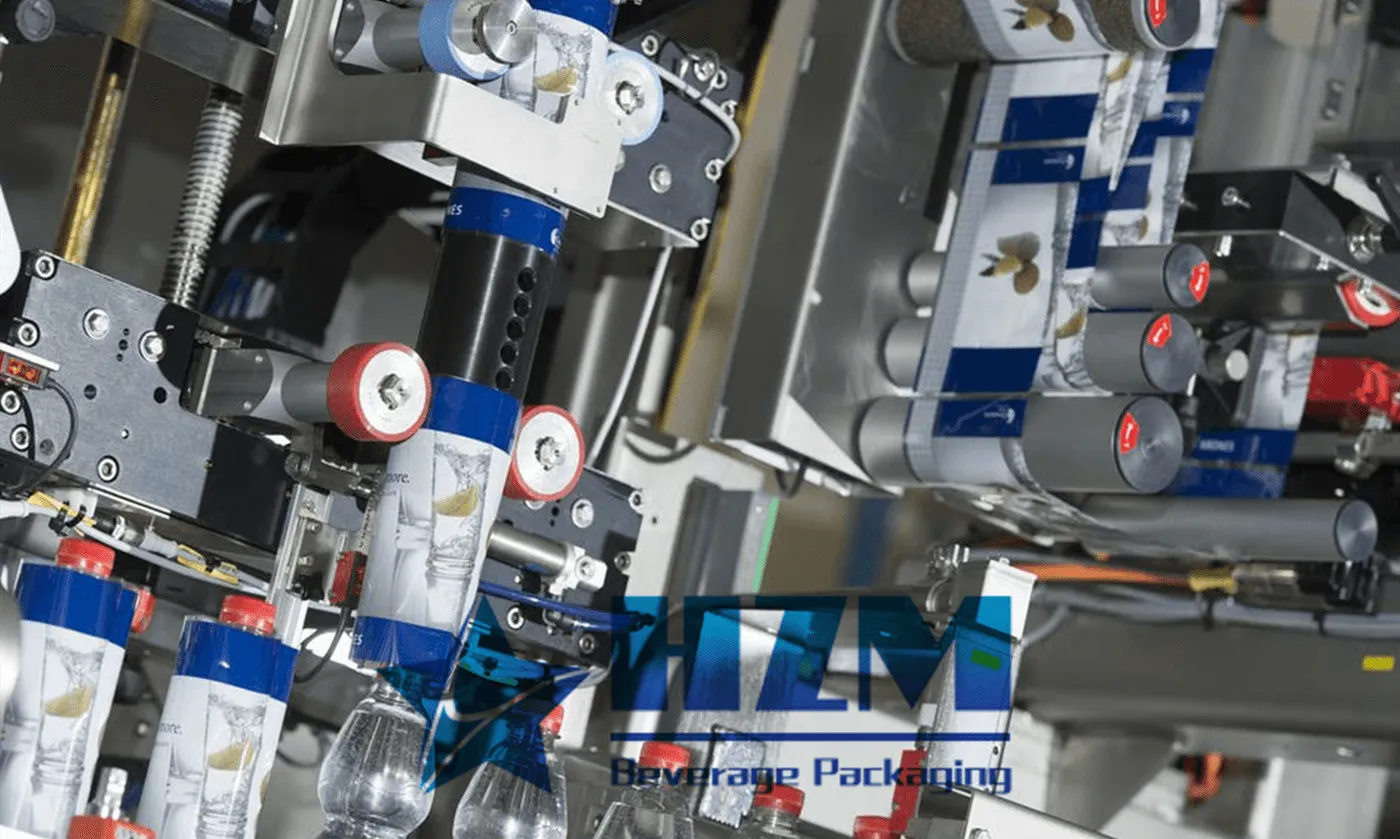

Automatic linear shrink sleece labeling machine is the advanced continous operation of the labeling machine. The labeling machine is mainly used for container labeling cylindrical, square or other special shape of detergents, beverages, mineral water, food etc. Labeling machine is control by PLC touch screen, all photo sensros are imported advanced configuration. The shrink labeling machine with high speed, high accuracy, stable performance, easy to operate and look elegant appearance.

Automatic Sleeve Labeling Machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

-

![Automatic Sleeve Labeling MachineIndustry application]() Mineral Water

Mineral Water

-

![Automatic Sleeve Labeling MachineIndustry application]() Juice

Juice

-

![Automatic Sleeve Labeling MachineIndustry application]() Carbonated Beverage

Carbonated Beverage

-

![Automatic Sleeve Labeling MachineIndustry application]() Canned Drink

Canned Drink

-

![Automatic Sleeve Labeling MachineIndustry application]() Wine

Wine

1.Synchronized transmission, any change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours, it’s maintenance is easy and maintain is simple, so it doesn’t influence production. 2.Double shrinking label feeding station, reasonable height which is convenient to fix the label; micro-computer auto figure which avoid enactment and adjustment .you only need to press it lightly, the label will detect and locate automatically. The change of label is quick and convenient. Besides, the cutting place is absolutely exact. 3.Label feeding equipment: driving synchronized tensility control the supply of label, the supply ability is 90meters per minute, volume label supply plane is ∮500mm, the internal diameter of paper tube will be 4′, 8′, 10′.the configuration of label feeding is stable tensility which enable the exact length of label and the stable, quick supply of label. 4.The newly designed cutter head use step by step motor driving which speed is high, action is exact, the cut is in order and the shrinking is beautiful. This design cooperated with the label synchronized location structure enable the precision of cut location within 1mm. 5.Special designed heat wind shrinking tunnel use high pressure wing machine which makes the shrink effect perfect. Compare with the traditional shrink tunnel which cannot shrink curved bottle, this head wind shrink tunnel can make the shrink effect satisfying. (BPH) (mm) (mm) (mm) (mm) (mm)Product Features

Product Configurations

Name

Supplier

PLC

Omron-Japan

Servo Motor&Controller

DELTA-Taiwan China

Inverter

DANFOSS-Denmark

Touch Screen

WEINVIEW-Taiwan China

Main Motor

ZHONGDA-China

Low Voltage Electrical Parts

SCHNEIDER-France

Sensor

KEYENCE-Japan

Product Parameters

Model

Capacity

Labeling accuracy

Bottle Diameter

Label Height

Label thickness

Dimension

SHB-150

9000

±1

φ28-φ125

30-250

0.035-0.13

2100*850*2000

SHB-250

15000

±1

φ28-φ125

30-250

0.035-0.13

2100*850*2000

SHB-350

21000

±1

φ28-φ125

30-250

0.035-0.13

2100*850*2000

SHB-400

24000

±1

φ28-φ125

30-250

0.035-0.13

2100*850*2000

SHB-450

27000

±1

φ28-φ125

30-250

0.035-0.13

2100*850*2000