Automatic linear shrink sleece labeling machine is the advanced continous operation of the labeling machine. The labeling machine is mainly used for container labeling cylindrical, square or other special shape of detergents, beverages, mineral water, food etc. Labeling machine is control by PLC touch screen, all photo sensros are imported advanced configuration. The shrink labeling machine with high speed, high accuracy, stable performance, easy to operate and look elegant appearance.

Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine

HZM Machinery Factory Direct Sales.

2 years warranty.

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

-

![Automatic Shrink Sleeve Bottles Labeling Capping Packing MachineIndustry application]() Mineral Water

Mineral Water

-

![Automatic Shrink Sleeve Bottles Labeling Capping Packing MachineIndustry application]() Juice

Juice

-

![Automatic Shrink Sleeve Bottles Labeling Capping Packing MachineIndustry application]() Carbonated Beverage

Carbonated Beverage

-

![Automatic Shrink Sleeve Bottles Labeling Capping Packing MachineIndustry application]() Canned Drink

Canned Drink

-

![Automatic Shrink Sleeve Bottles Labeling Capping Packing MachineIndustry application]() Wine

Wine

Technical parameters

| Model | Capacity (BPH) |

Labeling Accuracy (mm) |

Bottle Diameter (mm) |

Label Height (mm) |

Label Thickness (mm) |

Dimension (mm) |

| SHB-150 | 9000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-250 | 15000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-350 | 21000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-400 | 24000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-450 | 27000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

Features

1. With inverter speed, be free to adjust the speed when the motor is running, labeling capacity is free to control;

2. Automatic gluing, automatic calibration, automatic labeling, automatic photoelectric detection, high degree of automation, wide adaptation range, convenient adjustment, simple operation, attractive appearance, easy maintenance, cleaning;

3. Shaft material, the height adjustment of the machine parts used in all AISI304 stainless steel;

4. The machine has no bottle ,no labeling device and mortar thickness adjustment device;

5. Paste slot with stainless steel rollers with precision machining, glue as used with the check, and easy to clean;

6. Special rubber wheel by the number of road Process, not deformation, wear-resistant. On a the uniform thin plastic, glue amount of savings;

7. Pressure standard belt original Japan up to machines imported products, this belt core ply metal wire, and enhance the intensity of use, to avoid the phenomenon of thermal expansion and contraction and pumping of stomatal aperture changes other company products, stable pumping vacuum flow, thus ensuring stable conveying Label;

8. Labeling machine with PLC program automatic labeling process, compared with single-chip control actions achieve more stable, more convenient maintenance;

9. Machine processing precision and delicate, the basic components are standard accessories, convenient maintenance;

10. Machine basically configured for the import, quality assurance, better make it stable performance, the use of longer maintenance rate at the end.

Machine Details

Sleeve Labeling Machine

Application: PVC / PET / OPS label sleeve * Stainless steel Main Machine Frame / Famous electrical components (SIEMENS Plc controller ,Inverter ,Mitsubishi Moto

Steam Generator

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Steam Shrinking Tunnel

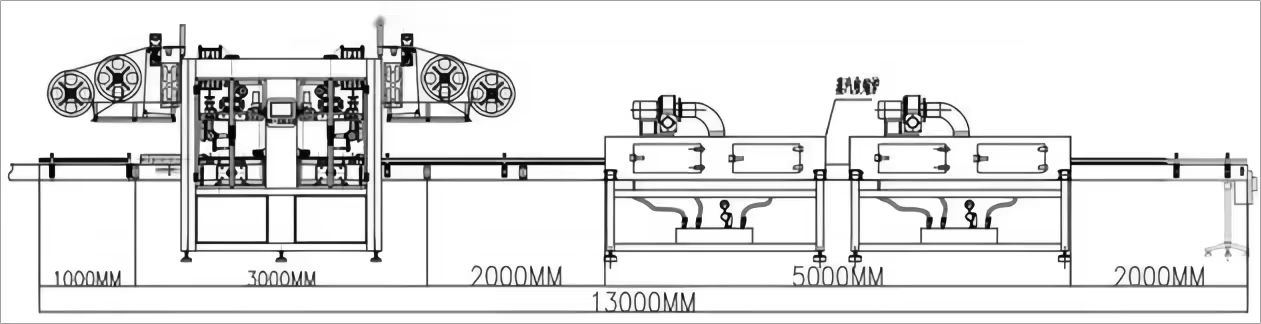

The heat of the steam shrinks the label set into thebottle and evenly attaches it to the bottle. The height ofthe steam pipe is adjustable, and it is also equippedwith a condensate drain tray and a steam exhaust fan

PLC control system

Stainless steel electric controller, adopting Mitsubishi PLC made in Japan