HZM Machinery, as an industry-leading manufacturer of automatic packaging equipment, is dedicated to providing customers with high-performance and cost-effective packaging solutions. The HZM Machinery Automatic BOPP Labeling Machine is designed for containers of various shapes and sizes, suitable for labeling applications in multiple industries including food and beverage, cosmetics, and pharmaceuticals.

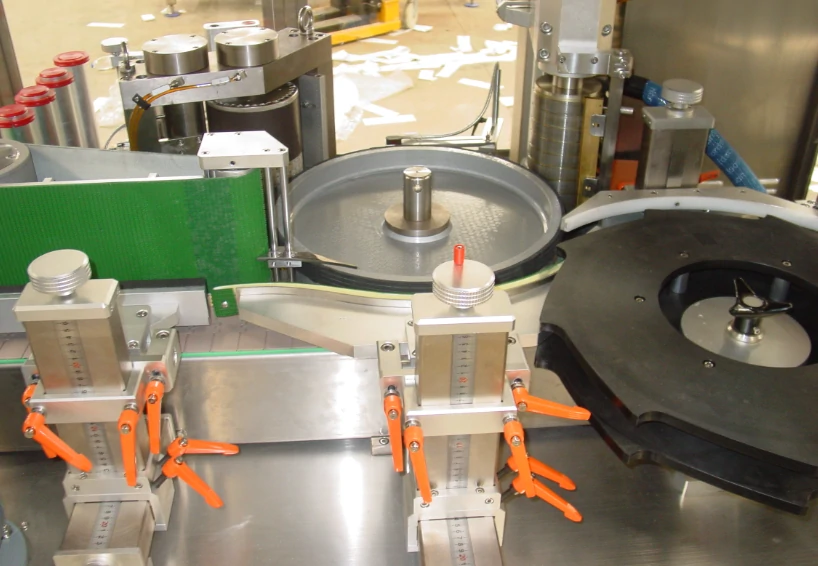

Automatic BOPP labeling machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

-

![Automatic BOPP labeling machineIndustry application]() Mineral Water

Mineral Water

-

![Automatic BOPP labeling machineIndustry application]() Juice

Juice

-

![Automatic BOPP labeling machineIndustry application]() Carbonated Beverage

Carbonated Beverage

-

![Automatic BOPP labeling machineIndustry application]() Canned Drink

Canned Drink

-

![Automatic BOPP labeling machineIndustry application]() Wine

Wine

Technical parameters

| Item | Details |

| Mechanical Dimensions | 2250L * 1500W * 2100H (mm) |

| Weight | 2500 KGS |

| Bottle Type | Cylindrical bottles |

| Bottle Material | PET, glass, metal |

| Bottle Diameter | 55-120 mm (according to the specifications) |

| Label Material | OPP, BOPP, composite membrane, paper (the whole volume of label) |

| Paper Tube Diameter | 6 inches (152 mm) |

| Labeling Speed | 12000 BPH |

| Power | AC 3φ 380V/50Hz |

| Air Pressure | 1.0 Mpa |

| Consumption Power | 13 KW |

Features

- Adopt the overall vertical labeling mode, automatically label cutting, automatic labeling.

- Microcomputer continuously variable control system, automatic detection in accordance with the feed, automatic adjustment of the production rate to maintain the labeling machine always in the best production rate.

- Applying the star-wheel feeding, to ensure not pour the bottle under high speed.

- Host Controller working with the frequency three-phase motor to control transmission.

- Label supply applying the servo motor synchronous tracking cutting, specially designed vacuum drum high-speed absorption, accurate and stable labeling.

- Transmission mode applying the linked design, stability and precision under high-speed labeling.

- Electronic automatic calibration label cutting system, cutting precision up to plus or minus 0.5 mm.

- Linked design encountering abnormal or unusual torque, the safety devices can automatically and immediately shut down the machine.

- Labeling position can be adjusted up and down.

- Hot melt machine below the set temperature, the labeling action can not be started.

- Without label, the machine automatically stops, and the alarm function starts.

- Label is not affixed, the machine automatically stops, and the alarm function starts.

Configurations list

| Item | Brand |

| Servo motor | DELTA-Taiwan |

| Servo driver | DELTA-Taiwan |

| Correction system | E+L-Germany |

| PLC | DELTA-Taiwan |

| Inverter | Danfoss-Germany |

| Decoder | Omron-Japan |

| Sensor | Keyence-Japan |

| Touch screen | WENVIEW-Taiwan |

| Machine material | SUS304-CHINA |

Factory Direct Pricing

HZM Machinery adopts a factory-direct sales model, eliminating middlemen to offer high-quality automated equipment at more favorable prices. The price of the HZM Automatic BOPP Labeling Machine varies based on specific models and configurations. To obtain a detailed quote, you can contact us at any time or leave a message on our website. We will provide a detailed quotation and professional technical support based on your specific needs.

The HZM Machinery Automatic BOPP Labeling Machine, with its efficient, precise, and multifunctional features, has become the ideal choice for many enterprises looking to improve production efficiency and product quality. The factory-direct pricing strategy brings tangible economic benefits to customers. If you are looking for a high-performance automatic labeling device, HZM Machinery will be your trustworthy partner. Feel free to contact us for more information and detailed quotations.