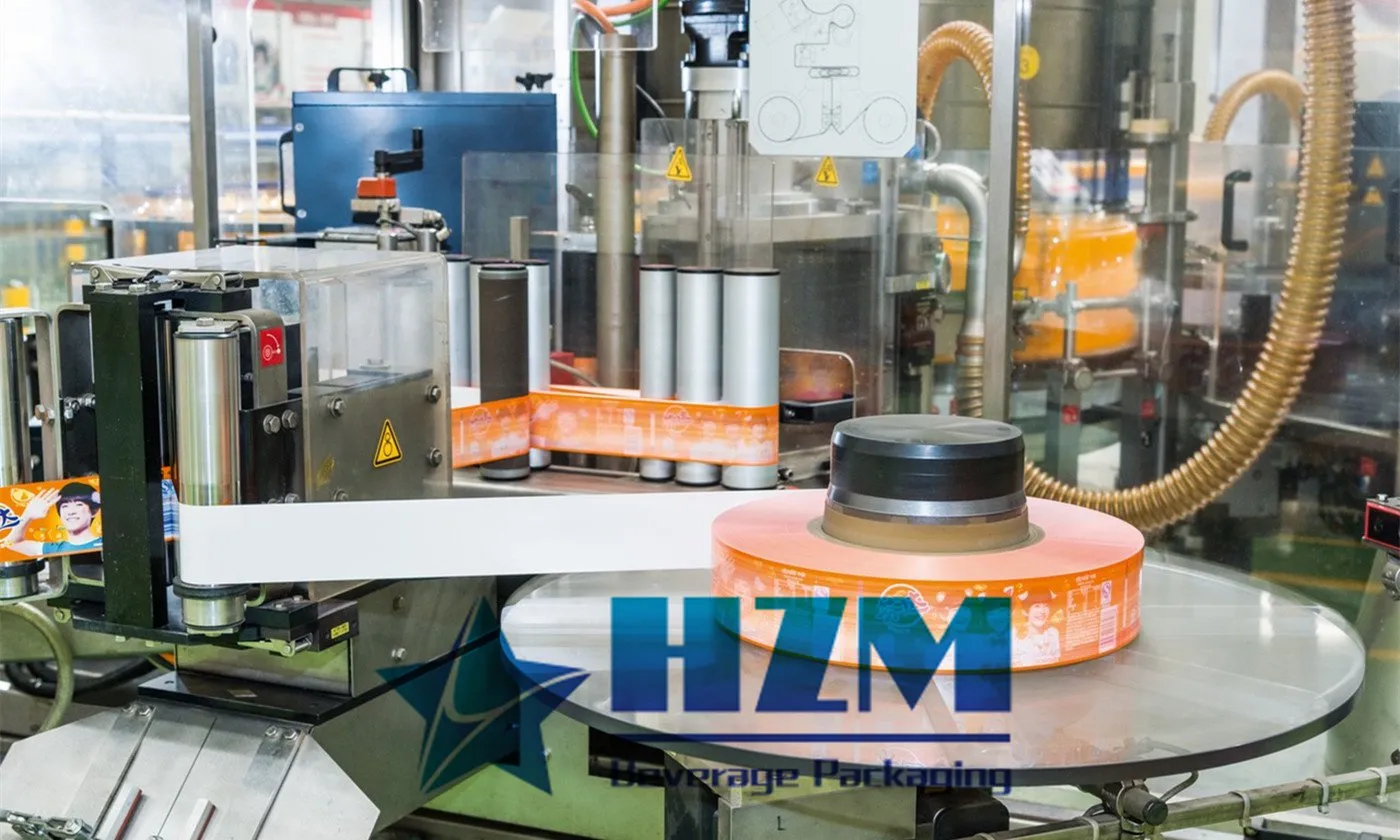

Bopp rotary type hot glue labeling machine is a new labeling machine with continuous operation. It is mainly used for cylindrical bottle labeling of OPP, pearl film, composite paper and other rolled material labels. New environmentally friendly materials such as OPP film are used to minimize production costs and save more than 30% production costs. At the same time, the use of environmentally friendly packaging materials is a trend in the development of the packaging industry. The labeling is driven and controlled by servo motor. All electric sensors are imported from Japan with advanced photoelectric, advanced configuration and PLC HMI. This machine has the advantages of fast labeling speed, high accuracy, stable performance, convenient operation, beautiful and flat appearance

Automatic BOPP Hot Glue Labeling Machine

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

-

![Automatic BOPP Hot Glue Labeling MachineIndustry application]() Mineral Water

Mineral Water

-

![Automatic BOPP Hot Glue Labeling MachineIndustry application]() Juice

Juice

-

![Automatic BOPP Hot Glue Labeling MachineIndustry application]() Carbonated Beverage

Carbonated Beverage

-

![Automatic BOPP Hot Glue Labeling MachineIndustry application]() Canned Drink

Canned Drink

-

![Automatic BOPP Hot Glue Labeling MachineIndustry application]() Wine

Wine

1.Adopt the overall vertical labeling mode, automatic label cutting, automatic labeling. 2.Microcomputer continuously variable control system, automatic detection in accordance with the feed, automatic adjustment of the production rate to maintain the labeling machine always in the best production rate. 3.OPP labeling machine Applying the star-wheel feeding, to ensure not pour the bottle under high speed. 4.Host Controller working with the frequency three-phase motor to control transmission. 5.Label supply applying the servo motor synchronous tracking cutting, specially designed vacuum drum high-speed absorption, accurate and stable labeling. 6.Transmission mode applying the linked design, stability and precision under high-speed labeling. 7.OPP labeling machine is equipped with centralized lubrication system which is easy to clean and maintain. (BPH) (mm) (mm) (mm) (kw) (mm)Product Features

Product Configurations

Name

Supplier

PLC

DELTA-Taiwan China

Servo Motor&Driver

DELTA-Taiwan China

Inverter

DANFOSS-Denmark

Touch Screen

WEINVIEW-Taiwan China

Label correction device

E+L-Germany

Low Voltage Electrical Parts

SCHNEIDER-France

Sensor

KEYENCE-Japan

Product Parameters

Model

Capacity

Labeling accuracy

Bottle Diameter

Label Height

Total Power

Dimension

RG-8K

8000

±1

φ45-φ100

35-140

12.0

2640*1800*2200

RG-12K

12000

±1

φ45-φ100

35-140

13.5

2640*1800*2200

RG-15K

15000

±1

φ45-φ100

35-140

13.5

3000*2100*2200

RG-18K

18000

±1

φ45-φ100

35-140

20.0

3000*2600*2200

RG-24K

24000

±1

φ45-φ100

35-140

25.0

3000*2600*2200