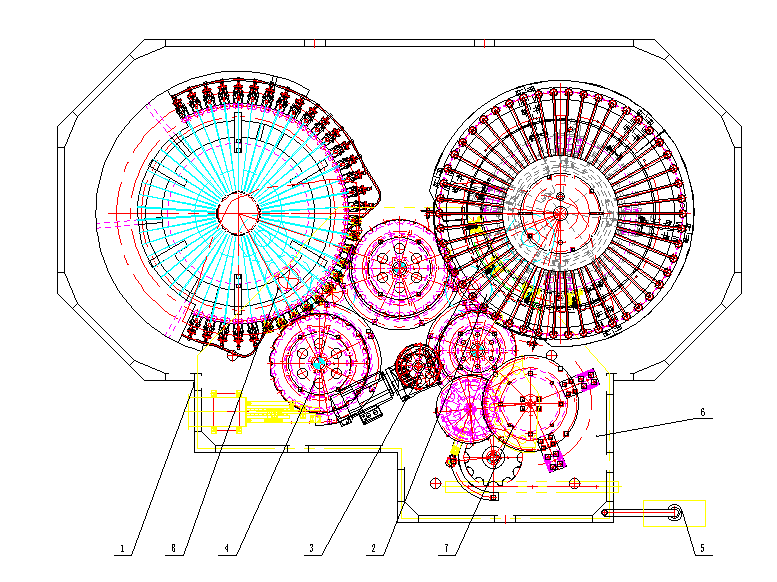

Working Process of the 3-in-1 Isobaric Mono-block Filling Machine

- Bottle Feeding and Preparation

- Bottles are transported via an air duct and evenly separated by the in-feed wheel.

- The in-feed wheel spaces the bottles at appropriate intervals and sends them to the rinser.

- Rinsing Process

- The rotary rinser clamps hold the bottle mouth and rotate the bottle 180° along a guide rail, positioning the bottle mouth downward.

- In the rinsing area, sterile water is sprayed from specialized nozzles on the bottle clamps to thoroughly rinse the inner walls of the bottles.

- After rinsing and draining, the bottles are rotated back 180° to return the bottle mouth upward.

- The rinsed bottles are transferred out of the rinser via the star wheel and sent to the filling machine.

- Filling Process

- Inside the filling machine, bottles are clamped by bottle-hanging plates.

- The bottles are lifted by a lifting component, which engages the filling valve by overcoming the filling valve spring.

- The filling process begins as the valve opens, and liquid is dispensed into the bottles.

- Once filling is complete, the bottles are released and lowered by the action of a cam.

- Capping Process

- Filled bottles are transferred to the capping machine via a transition wheel.

- The anti-rotation knife clamps the bottle neck to keep it upright and prevent rotation during capping.

- The capping heads, which revolve and rotate simultaneously, perform a series of actions:

- Grasping the cap.

- Placing the cap on the bottle.

- Tightening the cap to secure it.

- The capping process is completed under the precise control of a cam.

- Bottle Output

- Capped bottles are transferred to the bottle conveyor chain through the bottle conveying wheel.

- The conveyor chain transports the finished bottles out of the 3-in-1 filling machine for further processing or packaging.

Additional Features

- The entire process utilizes a bottle mouth hanging system to ensure smooth and stable bottle handling, reducing the risk of contamination or damage.

- The integrated design ensures high efficiency, precise operation, and reliable automation throughout the rinsing, filling, and capping processes.

PET Bottle 3-in-1 Filling Machine is the ideal choice for medium to large-scale beverage production companies, helping clients enhance their market competitiveness and meet diverse production demands.

TAG: Capping Monoblock Machine Monoblock filling machine monoblock Water Filling Machine Water Filling Machines

Update:Feb, 05 /2025

Author:HZM Machinery

Pageviews:285

PRODUCT

ARCTICLE

-

![12000BPH Pure Water Filling Line Debugging Successfully Completed]() 12000BPH Pure Water Filling Line Debugging Successfully CompletedMar , 24 /2023

12000BPH Pure Water Filling Line Debugging Successfully CompletedMar , 24 /2023 -

![Unveiling the Precision and Efficiency of Water Filling Machines]() Unveiling the Precision and Efficiency of Water Filling MachinesMar , 24 /2023

Unveiling the Precision and Efficiency of Water Filling MachinesMar , 24 /2023 -

![500ML 3 In1 Scale Monoblock Mineral Water Filling Machine]() 500ML 3 In1 Scale Monoblock Mineral Water Filling MachineJun , 09 /2023

500ML 3 In1 Scale Monoblock Mineral Water Filling MachineJun , 09 /2023 -

![How much does a small fully automatic bottled drinking water equipment cost?]() How much does a small fully automatic bottled drinking water equipment cost?Jan , 03 /2024

How much does a small fully automatic bottled drinking water equipment cost?Jan , 03 /2024 -

![The process flow of mineral water production line]() The process flow of mineral water production lineFeb , 06 /2024

The process flow of mineral water production lineFeb , 06 /2024

Home /

Home /