What Machines Are Used to Apply Plastic Labels on Beverage Bottles?

The plastic wrapping on beverage bottles is typically applied using specialized labeling machines. Common labeling methods include shrink sleeve labeling, hot melt glue labeling, self-adhesive labeling, and paper label labeling. Different labeling techniques are suitable for various beverage products and market needs. The widespread use of labeling machines not only enhances production efficiency but also ensures the aesthetic appeal and consistency of product packaging.

Based on different beverage types and market demands, labeling machines can adopt various labeling technologies to achieve precise and efficient label application.

Common Types of Labeling Machines

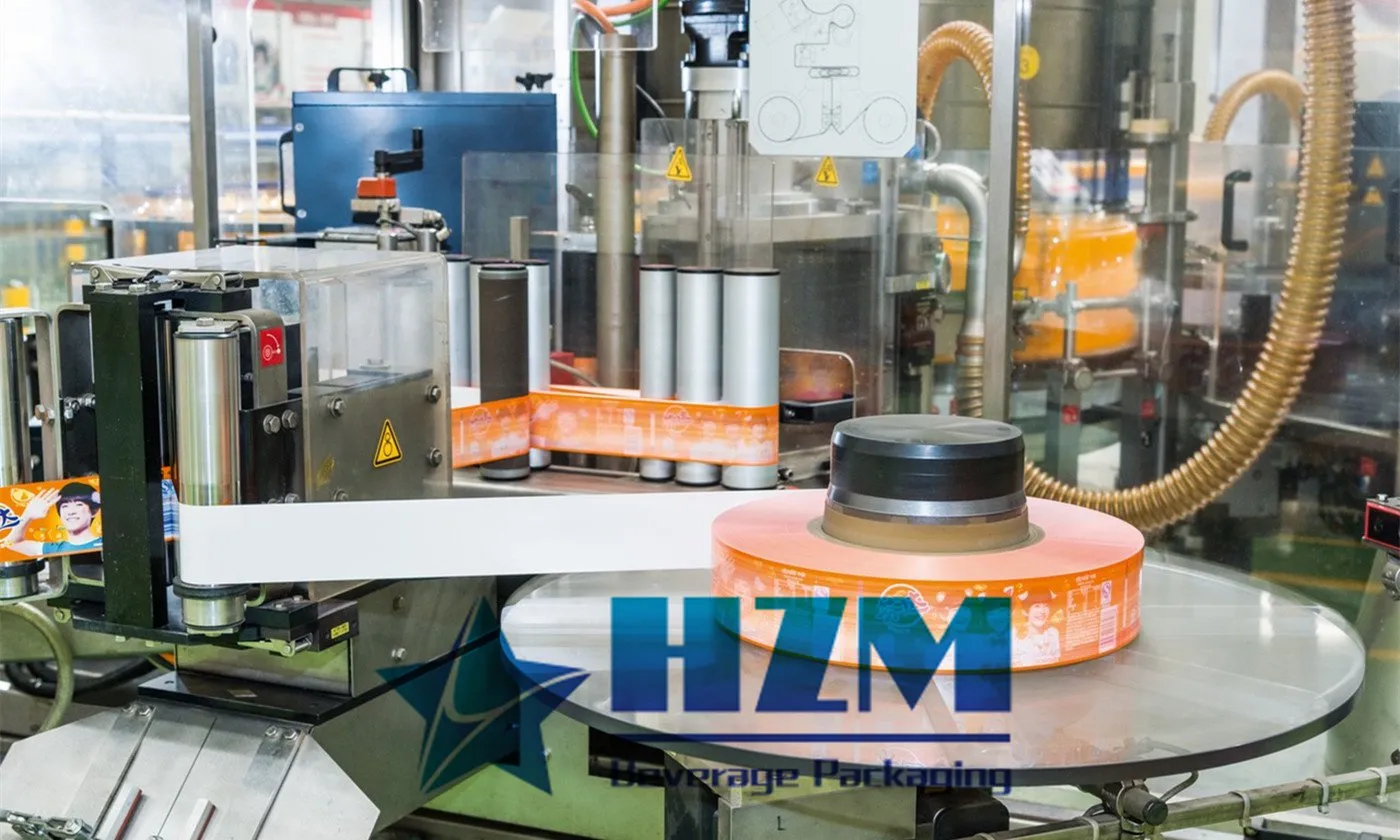

Shrink Sleeve Labeling Machine

- Applications: Commonly used for packaging products like juices and carbonated drinks.

- Working Principle: Shrink sleeve labeling machines use heat shrink technology to apply plastic labels to the bottle. Initially, the labels are pre-made in tubular form, which the machine cuts into individual labels and then slips onto the bottle. The bottle then passes through a hot air or steam tunnel, causing the label to shrink and tightly adhere to the bottle. This method provides 360-degree full coverage labeling, and the labels are firm and resistant to detachment.

Hot Melt Glue Labeling Machine

- Applications: Used for bottled water, milk, beer, etc.

- Working Principle: Hot melt glue labeling machines use hot melt adhesive to affix labels to the bottle. The machine first sprays hot melt glue on the back of the label and then quickly attaches the label to the bottle surface. This method offers strong adhesion, smooth and aesthetically pleasing labels, and is suitable for high-speed production lines.

Self-Adhesive Labeling Machine

- Applications: Primarily used for high-end beverages, small batch products, or products requiring special labels.

- Working Principle: Self-adhesive labeling machines use pre-glued labels that can be directly peeled from the backing paper and applied to the bottle. The machine uses rollers or brushes to smoothly apply the label to the bottle surface. This labeling method is simple to operate, ensures precise label placement, and is suitable for multi-variety, small-batch production.

Paper Label Labeling Machine

- Applications: Suitable for traditional style beverage packaging, such as some beers and juices.

- Working Principle: Paper label labeling machines typically use cold glue or paste as an adhesive to affix paper labels to the bottle. The machine evenly applies adhesive to the back of the label and then presses the label onto the bottle. The advantage of this method is that paper labels can be beautifully printed and offer certain anti-counterfeiting features.

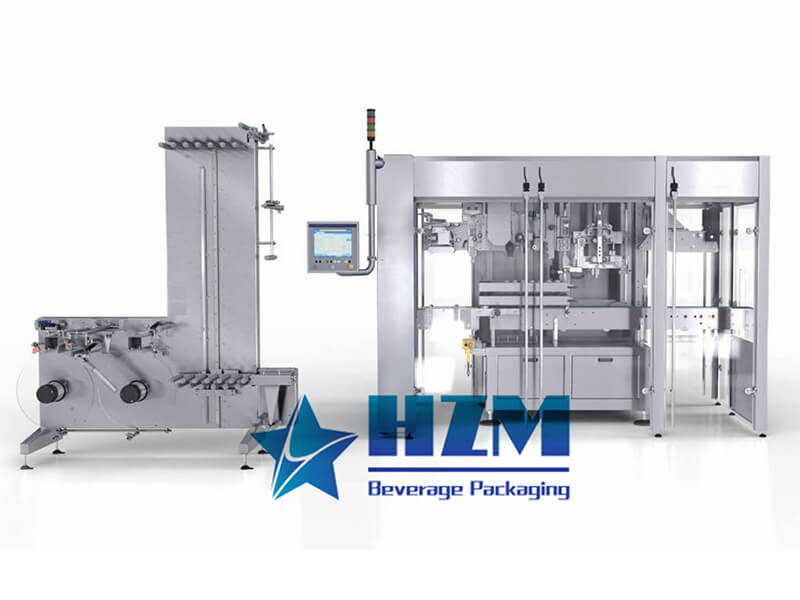

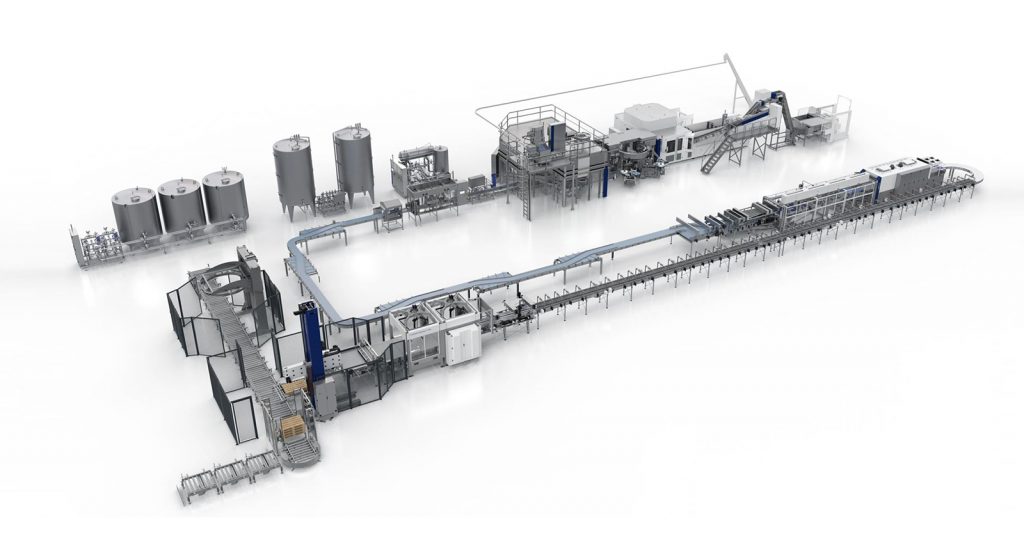

HZM Machinery is a professional manufacturer of beverage packaging equipment and can provide various types of bottle labeling machines. Our warranty period is 2 years after installation and commissioning. If any quality issues occur within these 2 years, we will take full responsibility and provide service. Feel free to contact us for equipment details and quotes.

TAG: labeling machines Sleeve Labeling Machines

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine Manufacturer

Drinking water production line – Bottled Water Filling Machine Manufacturer -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer

Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling Machine

Fully Automatic Beverage Filling Machine -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

![Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine]() Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine

Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine -

![Automatic High Speed Bottle Body Sleeve Labelling Machine]() Automatic High Speed Bottle Body Sleeve Labelling Machine

Automatic High Speed Bottle Body Sleeve Labelling Machine -

![Automatic Sleeve Labeling Machine]() Automatic Sleeve Labeling Machine

Automatic Sleeve Labeling Machine

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025 -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025

Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025 -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025

Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025 -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling MachineDec , 21 /2023

Automatic Pure Water Bottling Filling MachineDec , 21 /2023 -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling MachineOct , 11 /2023

Fully Automatic Beverage Filling MachineOct , 11 /2023 -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling MachineOct , 10 /2023

3-In-1 Water Bottle Filling MachineOct , 10 /2023 -

![What is a sleeve labeling machine? How does it work?]() What is a sleeve labeling machine? How does it work?Mar , 24 /2023

What is a sleeve labeling machine? How does it work?Mar , 24 /2023 -

![Automatic Sleeve Labeling Machines Purchasing price]() Automatic Sleeve Labeling Machines Purchasing priceMay , 21 /2023

Automatic Sleeve Labeling Machines Purchasing priceMay , 21 /2023 -

![How Do Label Machines Work?]() How Do Label Machines Work?Jun , 01 /2023

How Do Label Machines Work?Jun , 01 /2023 -

![Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling Machines]() Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling MachinesJun , 16 /2023

Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling MachinesJun , 16 /2023 -

![Choosing a High-Quality Automatic Sleeve Labeling Machine]() Choosing a High-Quality Automatic Sleeve Labeling MachineJun , 16 /2023

Choosing a High-Quality Automatic Sleeve Labeling MachineJun , 16 /2023 -

![HZM Machinery: Providing the Perfect Solution for Beverage Production Line Equipment]() HZM Machinery: Providing the Perfect Solution for Beverage Production Line EquipmentAug , 18 /2023

HZM Machinery: Providing the Perfect Solution for Beverage Production Line EquipmentAug , 18 /2023 -

![Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling Machine]() Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling MachineAug , 22 /2023

Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling MachineAug , 22 /2023 -

![Essential Maintenance Tips for Labeling Machines]() Essential Maintenance Tips for Labeling MachinesFeb , 29 /2024

Essential Maintenance Tips for Labeling MachinesFeb , 29 /2024