What is a CIP cleaning system?

CIP cleaning system, also known as Clean In Place system, refers to a safe and automatic cleaning system that can be achieved through simple operation methods without dismantling production equipment. This system has been introduced into almost all food, beverage, and pharmaceutical factories for cleaning machines and controlling microorganisms.

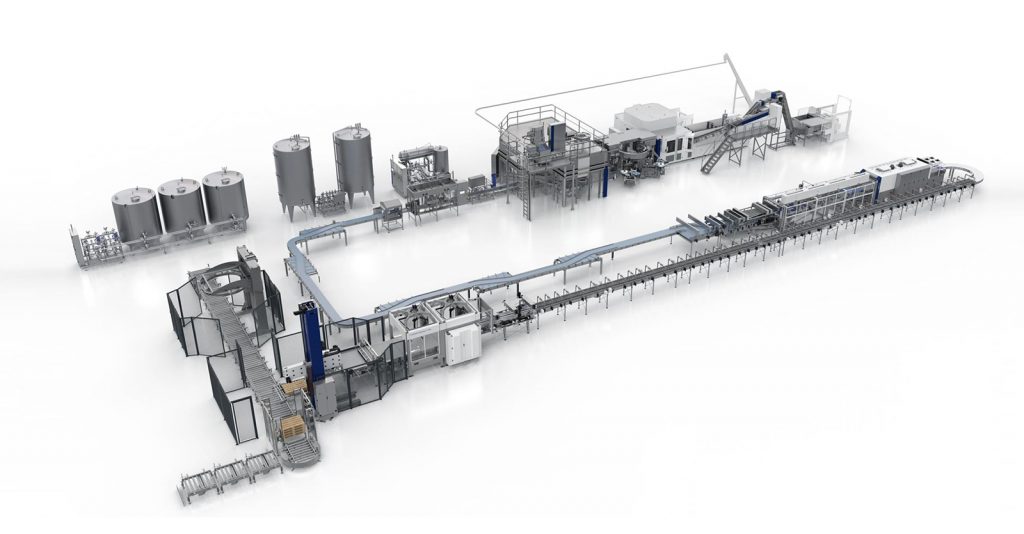

The CIP cleaning system mainly consists of acid tanks, alkali tanks, water tanks, concentrated acid/alkali drums, heating systems, diaphragm pumps, high and low-level sensors, online acid/alkali concentration detectors, and PLC touchscreen control systems. Among them, the acid tanks, alkali tanks, and water tanks are insulated tanks, and the acid/alkali tanks are also equipped with mixing systems.

The working principle of the CIP cleaning system is based on physical, chemical, and biological principles. During the cleaning process, the cleaning solution needs to have a certain degree of fluidity and impact force to flush out dirt and impurities through the interior of the equipment and pipelines. At the same time, cleaning agents such as alkaline cleaners, acid cleaners, and oxidizing agents are added to the cleaning solution, which can dissolve, decompose, or oxidize dirt and impurities, thereby improving the cleaning effect.

The advantages of the CIP cleaning system include rationalizing production plans and improving production capacity, preventing dangers during cleaning operations, saving labor, conserving cleaning agents, steam, water, and production costs, and increasing the service life of machine parts. This system is widely used in the food, beverage, and pharmaceutical industries, especially in food and beverage production enterprises with a high degree of mechanization.

Please note that when using the CIP cleaning system, it is necessary to select appropriate cleaning agents based on the cleaning objects and dirt characteristics of the equipment, and control their concentration and cleaning time to achieve the best cleaning effect. At the same time, it is also important to comply with relevant operating procedures and safety regulations to ensure the safety and effectiveness of the cleaning process.

TAG: CIP System

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine Manufacturer

Drinking water production line – Bottled Water Filling Machine Manufacturer -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer

Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling Machine

Fully Automatic Beverage Filling Machine -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

![CIP System]() CIP System

CIP System

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025 -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025

Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025 -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025

Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025 -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling MachineDec , 21 /2023

Automatic Pure Water Bottling Filling MachineDec , 21 /2023 -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling MachineOct , 11 /2023

Fully Automatic Beverage Filling MachineOct , 11 /2023 -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling MachineOct , 10 /2023

3-In-1 Water Bottle Filling MachineOct , 10 /2023 -

![Auto CIP System Six Valve Blowing Filling Capping Combine]() Auto CIP System Six Valve Blowing Filling Capping CombineJun , 09 /2023

Auto CIP System Six Valve Blowing Filling Capping CombineJun , 09 /2023 -

![20TPH Beverage Processing System For Juice Milk Tea For Sale]() 20TPH Beverage Processing System For Juice Milk Tea For SaleJun , 09 /2023

20TPH Beverage Processing System For Juice Milk Tea For SaleJun , 09 /2023 -

![Why Beverage Filling Machines Must Have CIP Cleaning Systems?]() Why Beverage Filling Machines Must Have CIP Cleaning Systems?Dec , 04 /2023

Why Beverage Filling Machines Must Have CIP Cleaning Systems?Dec , 04 /2023 -

![What equipment is needed to produce beverages?]() What equipment is needed to produce beverages?Mar , 28 /2024

What equipment is needed to produce beverages?Mar , 28 /2024