What is a Beverage Packaging Machine?

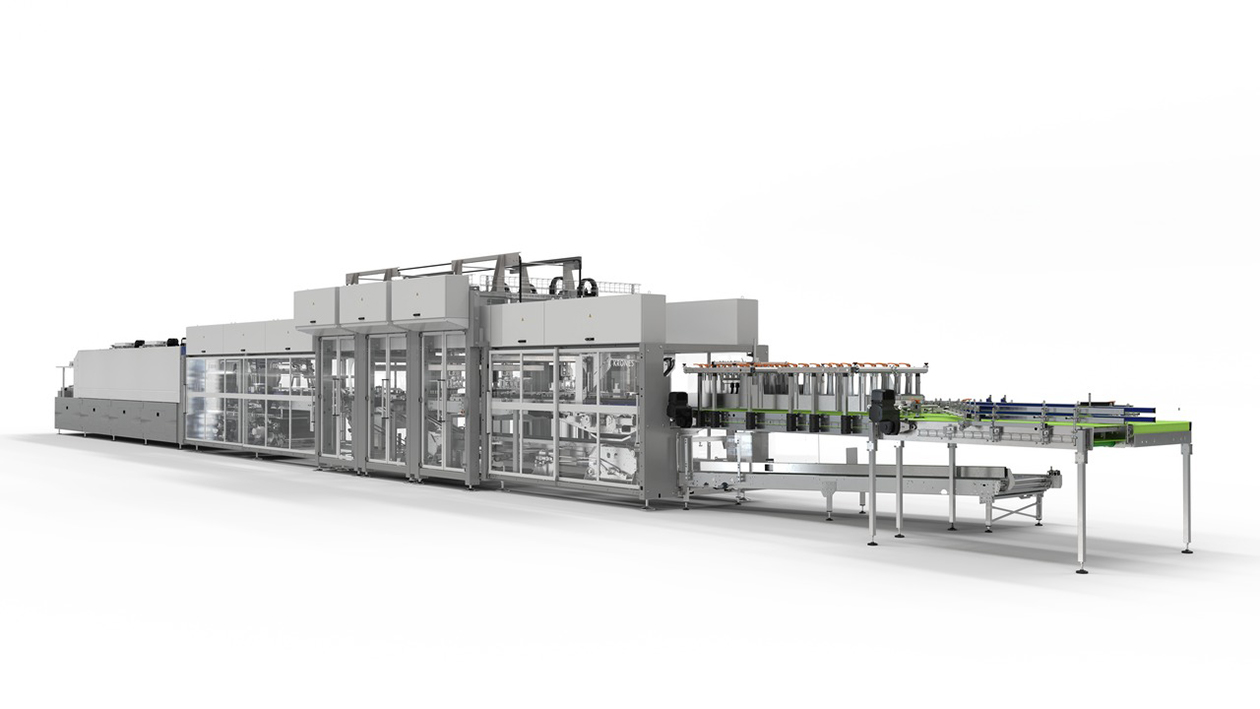

A beverage packaging machine is a sophisticated piece of equipment designed to automate the process of packaging various types of beverages, including soft drinks, juices, water, energy drinks, and more. These machines encompass a range of functionalities, from filling and capping to labeling and sealing, all within a seamless production line. By automating these tasks, beverage packaging machines enhance production efficiency, minimize human error, and ensure a hygienic and consistent packaging process.

Components of Beverage Packaging Machines:

- Bottle Feeder: This component feeds empty bottles into the packaging line, ensuring a continuous supply for the filling process.

- Filling System: The heart of the machine, the filling system accurately measures and fills beverages into bottles, cans, or other containers. Different technologies, such as volumetric or gravimetric filling, are employed based on the nature of the beverage.

- Capping and Sealing Mechanism: After filling, caps or lids are securely placed on the containers. Depending on the type of beverage and packaging, this component can include various sealing technologies such as screw caps, snap caps, or foil seals.

- Labeling Unit: The labeling unit applies adhesive labels to the containers, ensuring accurate branding and regulatory information.

- Date and Batch Coding: This feature prints important information like expiry dates and batch numbers on the packaging, enabling traceability.

- Packaging Line Conveyors: Conveyors transport containers through different stages of the packaging process, maintaining a smooth flow.

Versatile Applications:

Beverage packaging machines find applications in a wide array of industries, including:

- Soft Drinks and Carbonated Beverages: These machines efficiently handle carbonated beverages, ensuring accurate filling and airtight sealing to preserve carbonation.

- Juices and Flavored Waters: For juices and flavored waters, precision filling and capping help maintain freshness and prevent spoilage.

- Bottled Water: The demand for bottled water is met with consistent filling, capping, and labeling, ensuring safe and convenient consumption.

- Energy Drinks and Functional Beverages: These machines cater to beverages containing various ingredients, maintaining their potency and quality.

Distinctive Features:

- Automation and Efficiency: Beverage packaging machines reduce manual labor, accelerating the packaging process and minimizing errors.

- Customization: Machines can be adapted to various container shapes, sizes, and packaging requirements, offering flexibility to beverage producers.

- Hygiene and Safety: The closed and automated process reduces the risk of contamination, ensuring the safety of beverages.

- Consistency: The precision of beverage packaging machines guarantees uniformity in filling levels and sealing, maintaining product quality.

- Cost Savings: Although an initial investment, the long-term benefits of increased productivity and reduced wastage contribute to substantial cost savings.

In conclusion, beverage packaging machines play a pivotal role in the beverage industry, optimizing production processes and ensuring that consumers receive safe and consistent products. With their cutting-edge features and versatility, these machines are the driving force behind the rapid evolution of the beverage packaging landscape.

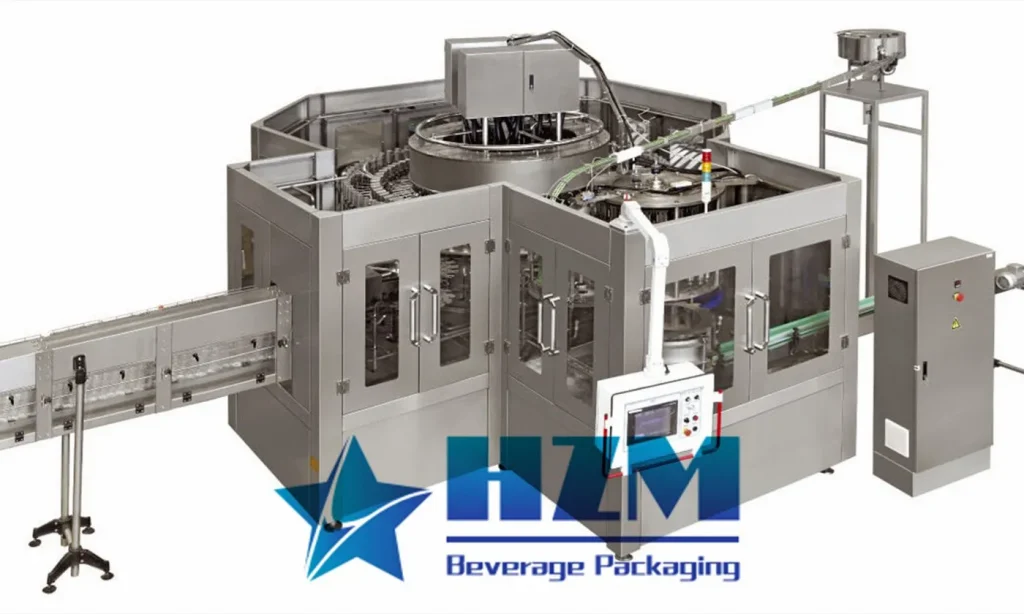

HZM Machinery is a professional beverage packaging machine manufacturer, dedicated to providing high-quality packaging solutions with its extensive experience and exceptional technology. Our team is well-versed in the demands of the beverage industry, designing and manufacturing beverage packaging equipment that is high-performing and reliable. Whether it's packaging requirements for various types of beverages or stringent demands for production efficiency and product quality, HZM Machinery is able to offer practical solutions that steer the course for our clients' business success.

TAG: Beverage Filling Machine Beverage Packaging Machine Carton Packing Machine Packaging machine

-

![Carton Package Machine]() Carton Package Machine

Carton Package Machine -

![Beverage Can Packaging machine]() Beverage Can Packaging machine

Beverage Can Packaging machine -

![Cold Drink Bottle Packing Machine]() Cold Drink Bottle Packing Machine

Cold Drink Bottle Packing Machine -

![Bottled Juice Packaging Machine]() Bottled Juice Packaging Machine

Bottled Juice Packaging Machine -

![PET Bottle CSD Beverage Filling Machine]() PET Bottle CSD Beverage Filling Machine

PET Bottle CSD Beverage Filling Machine -

![Glass Bottle CSD Beverage Filling Machine]() Glass Bottle CSD Beverage Filling Machine

Glass Bottle CSD Beverage Filling Machine -

![CSD Beverage Can Filling Machine]() CSD Beverage Can Filling Machine

CSD Beverage Can Filling Machine -

![Carbonated Drinks Filling Machine]() Carbonated Drinks Filling Machine

Carbonated Drinks Filling Machine -

![Automatic Drop Type Carton Packing Machine]() Automatic Drop Type Carton Packing Machine

Automatic Drop Type Carton Packing Machine -

![Automatic Carton Packing Machine]() Automatic Carton Packing Machine

Automatic Carton Packing Machine

-

![Important Questions To Consider Before Purchasing Carbonated Filling Machine]() Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023

Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023 -

![Classification of beverage filling machines]() Classification of beverage filling machinesMar , 24 /2023

Classification of beverage filling machinesMar , 24 /2023 -

![Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling Machine]() Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023

Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023 -

![Five Tips for Choosing the Right Packaging Machine for Your Business]() Five Tips for Choosing the Right Packaging Machine for Your BusinessApr , 24 /2023

Five Tips for Choosing the Right Packaging Machine for Your BusinessApr , 24 /2023 -

![Application of Juice Beverage Filling Machine in the Industry]() Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023

Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023 -

![How to Properly Maintain and Service Automatic Beverage Packaging Machines]() How to Properly Maintain and Service Automatic Beverage Packaging MachinesMay , 17 /2023

How to Properly Maintain and Service Automatic Beverage Packaging MachinesMay , 17 /2023 -

![Professional Beverage Packaging Machine Manufacturer]() Professional Beverage Packaging Machine ManufacturerJun , 06 /2023

Professional Beverage Packaging Machine ManufacturerJun , 06 /2023 -

![Advantages and Applications of Automatic Carton Packaging Machines]() Advantages and Applications of Automatic Carton Packaging MachinesAug , 10 /2023

Advantages and Applications of Automatic Carton Packaging MachinesAug , 10 /2023 -

![Overview of Packaging Machine Types and Classification Methods]() Overview of Packaging Machine Types and Classification MethodsAug , 11 /2023

Overview of Packaging Machine Types and Classification MethodsAug , 11 /2023 -

![Beverage Aseptic Filling Machine: The Perfect Combination of Freshness and Safety]() Beverage Aseptic Filling Machine: The Perfect Combination of Freshness and SafetyAug , 13 /2023

Beverage Aseptic Filling Machine: The Perfect Combination of Freshness and SafetyAug , 13 /2023 -

![The Role of Automatic Carton Packaging Machines in Beverage Production Lines]() The Role of Automatic Carton Packaging Machines in Beverage Production LinesAug , 14 /2023

The Role of Automatic Carton Packaging Machines in Beverage Production LinesAug , 14 /2023 -

![Design and Electrical Control of Fully Automatic Carton Packaging Machine]() Design and Electrical Control of Fully Automatic Carton Packaging MachineAug , 15 /2023

Design and Electrical Control of Fully Automatic Carton Packaging MachineAug , 15 /2023 -

![Automatic Carton Packaging Machine: An Automated Solution for Production Efficiency and Quality]() Automatic Carton Packaging Machine: An Automated Solution for Production Efficiency and QualityAug , 23 /2023

Automatic Carton Packaging Machine: An Automated Solution for Production Efficiency and QualityAug , 23 /2023 -

![How much does a bottling machine cost]() How much does a bottling machine costAug , 25 /2023

How much does a bottling machine costAug , 25 /2023 -

![Price of Beverage Packaging Machines: Meeting Diverse Needs with a Variety of Equipment]() Price of Beverage Packaging Machines: Meeting Diverse Needs with a Variety of EquipmentAug , 25 /2023

Price of Beverage Packaging Machines: Meeting Diverse Needs with a Variety of EquipmentAug , 25 /2023

Home /

Home /