What equipment is needed to produce beverages?

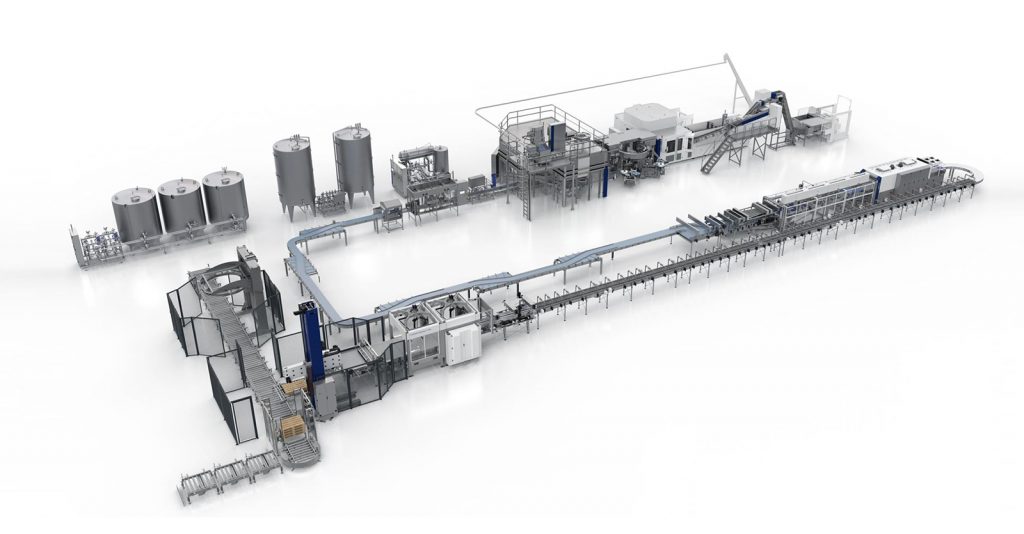

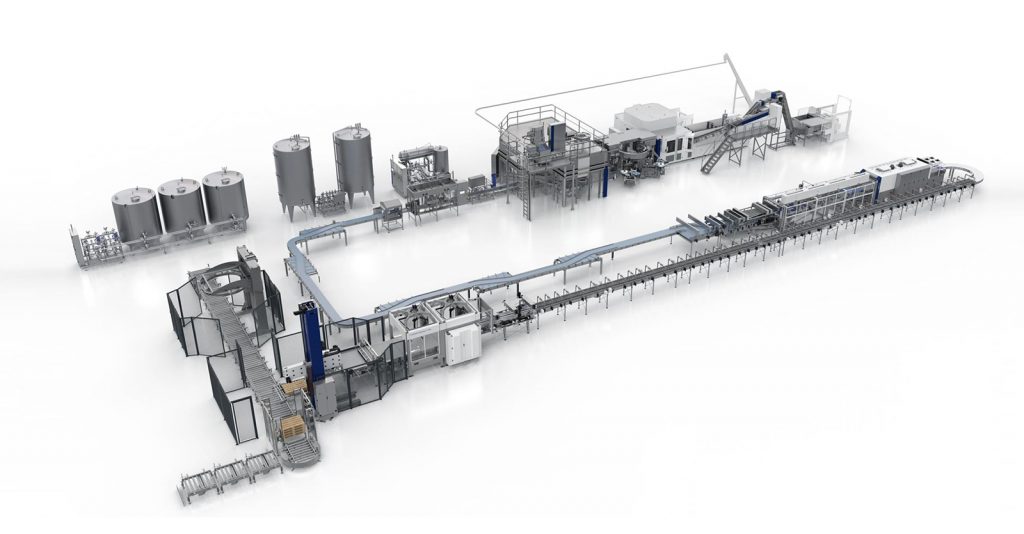

What equipment is needed to produce beverages? From water treatment to packaging, every step requires sophisticated equipment to ensure product quality and efficiency. The main equipment includes water treatment equipment, bottle rinsers, filling machines, sealing machines, sterilization equipment, CIP cleaning in place machines, filtration equipment, packaging equipment, etc. These devices were produced with the emergence of the beverage industry and have continued to develop with the development of the beverage industry.

Equipment introduction

1. Water treatment equipment: In the core process of beverage production, the first indispensable thing is water treatment equipment. Because water is the main component of beverages, the quality of the water directly affects the quality of the beverage. Water treatment equipment can remove impurities and harmful substances from water to ensure the purity of beverages.

2. Bottle rinser: It is responsible for cleaning the bottles to ensure that there are no residues inside the bottles to prepare for subsequent filling work. Next comes the filling machine, which is responsible for accurately injecting the processed beverage liquid into the bottle. The design of the filling machine requires precision and efficiency to ensure that the filling volume of the beverage meets the standards.

3. Filling machine and sealing machine: The filling machine can accurately fill the raw materials into bottles. The sealing machine seals the bottle mouth to prevent beverage leakage and contamination. With the development of technology, the sealing forms of sealing machines are also constantly innovating, such as screw caps, crown caps, etc., which have greatly improved the sealing performance and shelf life of beverages.

4. Sterilization equipment: After filling and sealing, the beverage needs to be sterilized to eliminate possible microorganisms and ensure the hygiene and safety of the beverage. Sterilization equipment usually uses high temperature or ultraviolet rays to sterilize to ensure the quality of beverages.

5. CIP cleaning machine: an important equipment to keep the equipment clean and hygienic. It can clean the production equipment regularly to prevent cross-contamination and bacterial growth.

Development History

As early as 1890, the United States manufactured the first glass bottle filling machine, laying the foundation for automated production in the beverage industry. In 1912, with the advancement of technology, the invention of the crown capping machine made beverage packaging more convenient. Subsequently, the advent of a filling and capping unit that integrated filling and capping further improved production efficiency.

At the beginning of the 20th century, Germany also began to manufacture manual filling machines and capping machines, marking the rise of Europe in beverage production equipment technology. Today, countries such as Germany, the United States, Italy and Sweden have relatively high technical levels of beverage production equipment. They continue to introduce new equipment and lead the development of global beverage production technology.

In terms of the technical level of beverage production equipment, countries such as Germany, the United States, Italy and Sweden have always been in the leading position. Equipment manufacturers in these countries continue to develop new technologies and new materials to promote the development of beverage production equipment in the direction of higher efficiency and higher quality.

Although the beverage production equipment market in Asia started late, it is developing rapidly. In particular, Chinese manufacturers have occupied a place in the global market with their favorable prices, high quality and excellent services. Today, China has become one of the world's largest exporters of beverage production equipment and has made important contributions to the development of the global beverage industry.

manufacturer

As a beverage production equipment manufacturer in China, HZM Machinery uses its excellent technical strength and rich experience to provide high-quality equipment and excellent services to customers around the world. HZM Machinery provides sterilization equipment, CIP cleaning machines, filtration equipment and packaging equipment. The excellent performance of these equipment provides reliable support for every aspect of beverage production and ensures product safety and hygiene.

TAG: Beverage Filling Machines CIP System UHT Sterilizer

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?