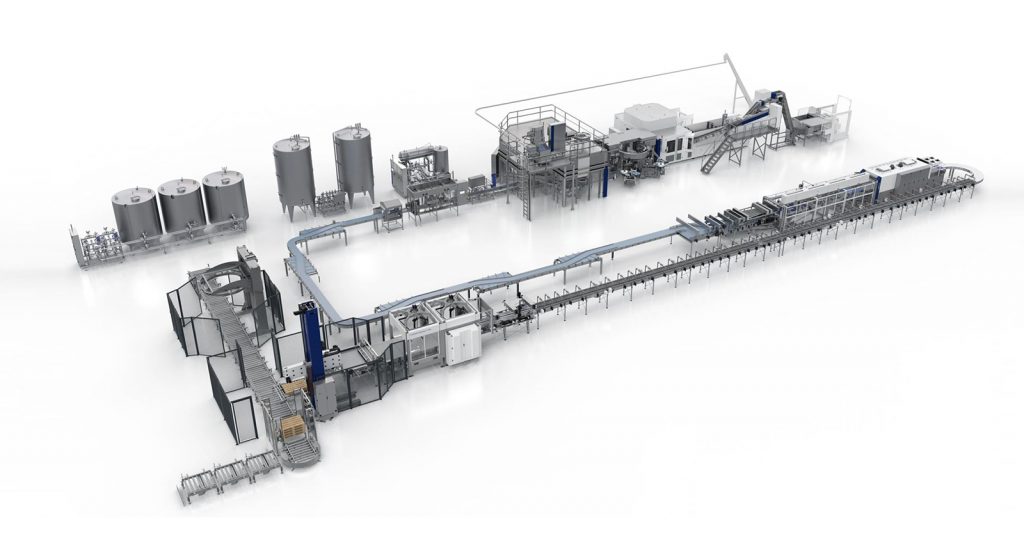

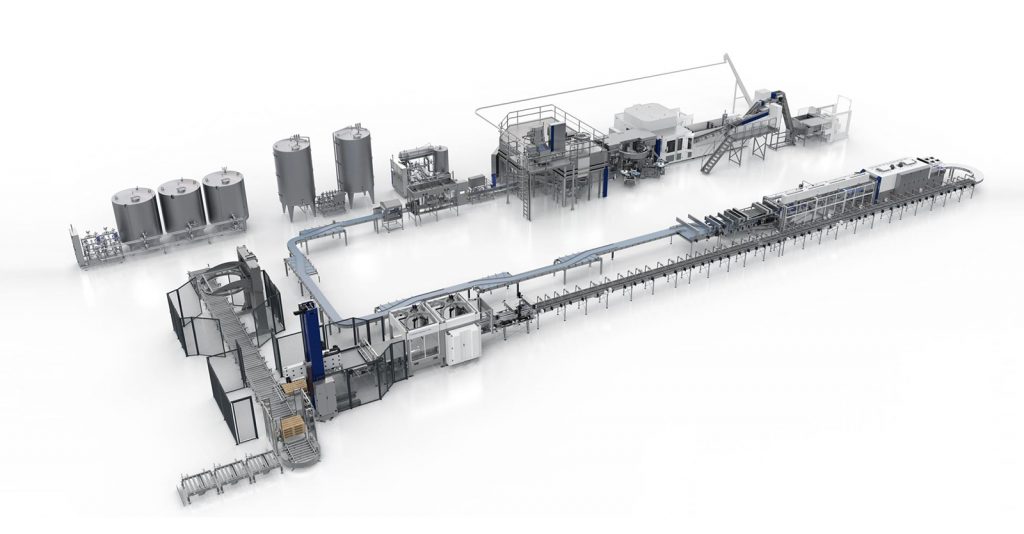

Water Filling Line Turnkey Engineering Solutions

Water filling line is an automated production line used for filling various liquid products such as water, beverages, and juices. It typically includes a series of equipment and machines for cleaning, filling, capping, and packaging liquid products. The scale and functionality of water filling lines can be customized according to production requirements, ranging from small-scale manual production lines to large-scale fully automated ones.

On the other hand, turnkey engineering refers to a project engineering model where the ownership and responsibility of the entire project are transferred from the construction party to the client. In this model, the construction party completes the entire project according to agreed-upon standards and requirements and hands over the "key" to the client, allowing them to formally take over and utilize the project.

Water filling line turnkey engineering is an engineering model that involves the complete process of designing, constructing, debugging, and finally delivering a water filling line for use. This engineering model ensures smooth project delivery and quality assurance.

Let's delve into the details of each phase:

1.Planning and Design Phase

During this phase, the project team collaborates with the client to determine project requirements and objectives. This includes specifying production capacity, types and specifications of filled products, equipment selection, and production line layout. Based on these requirements, engineers and design teams develop detailed design plans and construction drawings to ensure that the production line design meets the client's requirements.

2.Procurement and Equipment Installation Phase

Once the design plans are approved, the procurement of necessary equipment and machinery commences. This includes filling machines, cleaning machines, capping machines, packaging machines, and more. After the equipment arrives on-site, the construction team is responsible for installation, commissioning, and interconnecting various equipment to ensure their proper functioning.

3.Debugging and Testing Phase

After the equipment installation is completed, the entire production line needs to be debugged and tested. This involves ensuring the smooth mechanical operation of the equipment, proper functioning of sensors and control systems, and smooth flow of automation processes. Careful debugging and testing are conducted to ensure that the production line operates as intended.

4.Training and Operation Manual Compilation Phase

Once the production line has passed the testing phase and is operating smoothly, operators need to undergo training to learn how to operate and maintain the production line correctly. Additionally, operation manuals are compiled, providing detailed instructions on operation steps, maintenance requirements, and safety precautions for the reference of the operators.

5.Delivery and Acceptance Phase

After all the previous work is completed, the production line is handed over to the client. At this stage, the client conducts acceptance tests to ensure that the production line meets the contractual requirements and design specifications. Once the acceptance is passed, the delivery process is concluded, and the client assumes the operation and management of the production line.

In summary, water filling line turnkey engineering encompasses the entire process from planning, design, procurement, installation, commissioning, and delivery. Its objective is to ensure the construction of the production line according to requirements and specifications, ultimately facilitating a smooth handover to the client. By adopting this engineering model, clients can actively participate in the project from the beginning and receive a complete production line that meets their requirements.

HZM Machinery is a leading company specializing in providing water filling line turnkey engineering. With years of industry experience and expertise, we are committed to delivering high-quality engineering solutions to our clients. Whether you require the construction of a small-scale manual production line or a large-scale fully automated one, we can meet your needs.

Choosing HZM Machinery as your partner for water filling line turnkey engineering, you will benefit from professional services, high-quality equipment, and comprehensive engineering solutions. Please contact us to embark on a successful water filling line project together!

TAG: Water Filling Line Water Filling Machine

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?