Water Bottling Plant Cost

The cost of establishing a water bottling plant can vary depending on several factors, including the size of the plant, location, type of equipment, level of automation in the production line, and local regulatory requirements.

Here are some factors that may affect the cost:

- Land and Building: The cost of purchasing or leasing suitable land and building for the plant.

- Water Source Development: Additional costs if drilling or other methods are needed to access a water source.

- Purification System: Equipment and technology used for water treatment and purification.

- Bottling Line: Machinery needed for bottle washing, filling, capping, labeling, and packaging.

- Warehouse and Logistics: Storage space for finished products and facilities for transportation to the market.

- Quality Control Laboratory: Testing equipment to ensure the product meets safety standards.

- Energy Supply: Operating costs such as electricity, natural gas, etc.

- Human Resources: Employee wages, training, and associated benefits.

- Licenses and Compliance: Costs for obtaining necessary government permits and complying with industry standards.

- Marketing and Distribution: Brand building, advertising, and setting up a sales network.

Startup capital can range from hundreds of thousands to millions of dollars or even more. For small-scale local operations, initial investments may be relatively low, while large-scale automated international brands may require a significantly larger investment.

In addition, ongoing operational costs should be considered, such as raw materials (bottles, caps, labels), utilities (water, electricity), maintenance, taxes, and other recurring expenses. When planning finances, it is important to carefully assess all these factors and develop a detailed business plan to ensure the sustainability and profitability of the project.

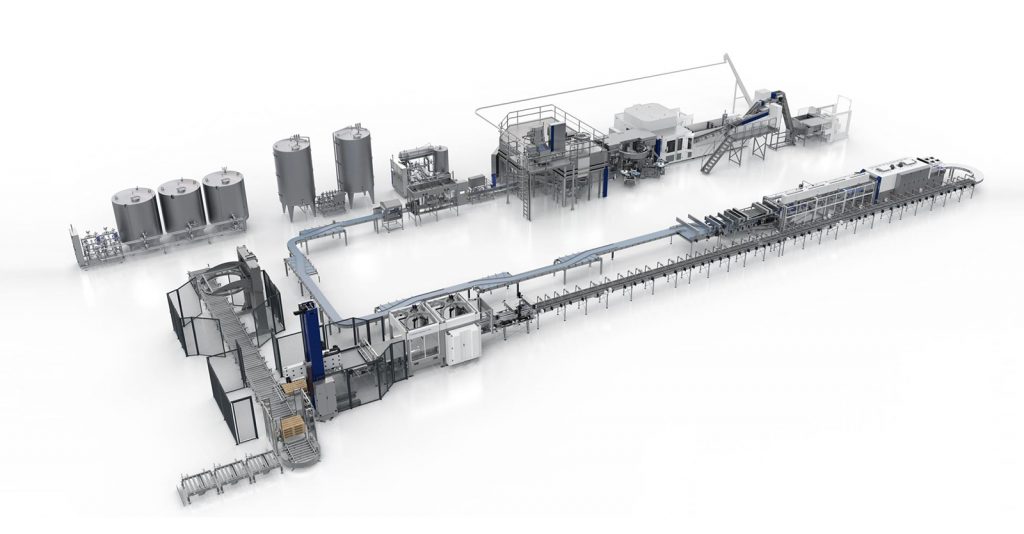

What equipment is needed to establish a water bottling plant?

Establishing a water bottling plant requires a range of equipment to complete the entire process, from water treatment to the final packaging and dispatch of the product. Below is a list of essential equipment:

- Water Treatment System:

- Water Pump: Used to extract groundwater or surface water.

- Filters (sand, activated carbon, etc.): To remove impurities from the water.

- Reverse Osmosis (RO) Unit/Ultrafiltration (UF) Unit: Further purifies water, removing microorganisms and dissolved solids.

- UV Sterilizer: For disinfection.

- Ozone Generator (optional): Enhances disinfection and helps improve water taste.

- Bottling Line:

- Bottle Washing Machine: Ensures the bottles are clean and hygienic.

- Filling Machine: Fills the purified water into the bottles.

- Capping Machine: Seals the bottles with caps.

- Labeling Machine: Applies labels to the products.

- Packaging Machine: Packages individual bottles into boxes or other forms of packaging.

- Quality Control Equipment:

- Laboratory Testing Instruments: Includes pH meters, conductivity meters, turbidity meters, etc., to monitor water quality parameters.

- Microbial Testing Equipment: Ensures the product meets food safety standards.

- Warehouse and Logistics Facilities:

- Warehouse Shelving: For storing finished products and raw materials.

- Forklift: For moving goods.

- Refrigeration Equipment (if producing products that require cold storage).

- Auxiliary Equipment:

- Compressed Air System: Powers pneumatic equipment.

- Chemical Storage and Dosing System for Water Treatment: Maintains water quality stability.

- Wastewater Treatment Facility: Treats wastewater produced during the production process to meet discharge standards.

- Automation Control System (optional):

- PLC Control System: For automated control of the production line.

- SCADA System: For data collection and analysis, monitoring the entire production process.

When choosing the right equipment, consider your production capacity needs, budget constraints, and local regulatory requirements.

HZM Machinery – Professional Water Bottling Plant Solutions Provider

HZM Machinery is dedicated to providing comprehensive water bottling production solutions to clients. From water treatment to final product packaging, we offer a one-stop service to ensure your project runs efficiently and reliably. Our services include but are not limited to:

- Customized Design and Planning: Tailored plant layout and production line configuration based on your specific needs and budget.

- Advanced Production Equipment: Covering water treatment systems, bottling lines, quality control equipment, and warehouse logistics facilities, all using industry-leading technology.

- Comprehensive Technical Support: Our expert technical team offers full support, from installation and commissioning to staff training, ensuring rapid production startup.

- Turnkey Project Solutions: We provide full services from project planning to operational launch, allowing you to easily establish your own water bottling plant.

Choosing HZM Machinery means choosing high-quality products and services. We look forward to working with you and embarking on a successful journey together. Contact us now for detailed quotes and more information!

Contact us

TAG: Water Bottling Line Water Bottling Machine Water Bottling Plants

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?