User Guide for Automatic Sleeve Labeling Machine

Introduction: The Automatic Sleeve Labeling Machine is an essential piece of equipment widely used in various industries for labeling processes. To ensure efficient operation and safe use of the machine, this article provides tips for using the equipment effectively, maintaining and servicing it, troubleshooting common issues, and following proper safety procedures.

- Tips for Using:

- Before operating, ensure proper installation of labels and adjustment of machine parameters for accurate labeling and fit.

- Regularly inspect the conveying system and heat-shrinking device to ensure smooth operation and prevent label jamming or improper shrinking.

- Ensure precise alignment and stable feeding of bottles for accurate label positioning and fit.

- Adjust the speed and temperature settings according to product requirements for optimal labeling and label shrinkage results.

- Maintenance and Servicing:

- Regularly clean the machine's surfaces and internal components to ensure proper functioning and hygiene standards.

- Check the tightness of the transmission system and belts, adjusting as necessary.

- Pay attention to lubrication, ensuring proper lubrication of moving parts and transmission mechanisms to reduce wear and friction.

- Replace worn-out parts and accessories periodically to maintain efficient machine performance.

- Troubleshooting:

- In case of machine malfunction, stop operation immediately and cut off power to ensure safety.

- Refer to the machine's user manual and technical specifications for troubleshooting guidance and identification of potential issues.

- If unable to resolve the problem, contact the manufacturer or seek assistance from professional technicians for repair and support.

- Safety Operation:

- Always adhere to safety procedures and operating guidelines when using the Automatic Sleeve Labeling Machine.

- Operators should receive relevant training on the machine's safety procedures and emergency shutdown protocols.

- Maintain a clean and tidy work area around the machine, avoiding obstructions that may hinder operation or pose safety hazards.

- Use personal protective equipment, such as gloves and safety goggles, to ensure personal safety.

Conclusion: Understanding the tips for using, maintaining, troubleshooting, and safely operating an Automatic Sleeve Labeling Machine is crucial for improving work efficiency, ensuring long-term stability of the equipment, and safeguarding the well-being of operators. By following proper operating procedures and conducting regular maintenance, you can make the most of this essential equipment and ensure its smooth operation throughout the production process. Remember, prioritizing safety is always essential, so always keep safety protocols in mind and ensure the safety of the operators.

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine Manufacturer

Drinking water production line – Bottled Water Filling Machine Manufacturer -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer

Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling Machine

Fully Automatic Beverage Filling Machine -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

![Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine]() Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine

Automatic Shrink Sleeve Bottles Labeling Capping Packing Machine -

![Automatic High Speed Bottle Body Sleeve Labelling Machine]() Automatic High Speed Bottle Body Sleeve Labelling Machine

Automatic High Speed Bottle Body Sleeve Labelling Machine -

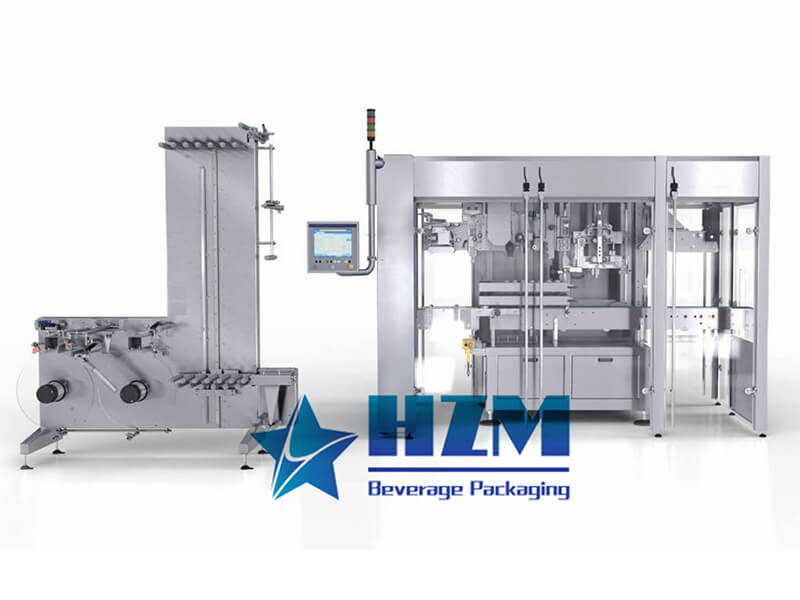

![Automatic Sleeve Labeling Machine]() Automatic Sleeve Labeling Machine

Automatic Sleeve Labeling Machine

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025 -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025

Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025 -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025

Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025 -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling MachineDec , 21 /2023

Automatic Pure Water Bottling Filling MachineDec , 21 /2023 -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling MachineOct , 11 /2023

Fully Automatic Beverage Filling MachineOct , 11 /2023 -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling MachineOct , 10 /2023

3-In-1 Water Bottle Filling MachineOct , 10 /2023 -

![What is a sleeve labeling machine? How does it work?]() What is a sleeve labeling machine? How does it work?Mar , 24 /2023

What is a sleeve labeling machine? How does it work?Mar , 24 /2023 -

![Automatic Sleeve Labeling Machines Purchasing price]() Automatic Sleeve Labeling Machines Purchasing priceMay , 21 /2023

Automatic Sleeve Labeling Machines Purchasing priceMay , 21 /2023 -

![Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling Machines]() Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling MachinesJun , 16 /2023

Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling MachinesJun , 16 /2023 -

![Choosing a High-Quality Automatic Sleeve Labeling Machine]() Choosing a High-Quality Automatic Sleeve Labeling MachineJun , 16 /2023

Choosing a High-Quality Automatic Sleeve Labeling MachineJun , 16 /2023