Two Recycling 15000 BPH Blowing Filling Capping Combine

| Material: | Stainless Steel | Process: | Pressure Filling System |

|---|---|---|---|

| Certification: | GB/T19001-2000 | Type: | Filling Machine |

| Capacity: | 15000BPH-54000BPH | Applicable Bottle Type: | 200ml-1500ml |

| Function: | Water Bottle Filling Machine | Number Of Filling Head: | 24 |

| Number Of Capping Head: | 8 | Productivity: | 15,000 BPH (500ml) |

| Applicable Bottle: | Dia.: Φ60-Φ90, Height: 180-260 | Main Motor Power: | 5.5+7.5kW |

| Weight: | 15,000kg | ||

| High Light: | 1500 bph Blowing Filling Capping Combine, 54000 bph glass bottle capping machine, 1500 Bph Blowing Filling Capping Combiblock | ||

Two Recycling 15000 BPH Blowing Filling Capping Combine

Stainless Steel Filling Machine Blowing Filling Capping Combine

The blowing, filling and screwing integrated machine refers to the complete action of blowing, filling and capping on a single device, and the innovative packaging technology from preforms to bottled liquid products is completed by a single machine. The integrated system that integrates the trinity solution of blowing, filling and capping reduces the intermediate transfer, empty bottle handling, stacking, and storage processes, reduces the risk of empty bottle contamination, improves packaging sanitary conditions, and improves the entire line of production At the same time, the system energy consumption can be greatly reduced, which greatly reduces the comprehensive production cost of beverage manufacturers.

Technical Parameters of Integrated Blowing Filling Capping System

|

Number of Bottle Feed Cavity |

8 |

|

Number of Filling Head |

24 |

|

Number of Capping Head |

8 |

|

Productivity |

15,000 BPH (500ml) |

|

Applicable Bottle |

Dia.: Φ60-Φ90, height: 180-260 |

|

Overall Dimension |

11,100×7,780×3,840 (L×W×H) |

|

Main Motor Power |

5.5+7.5kW |

|

Weight |

15,000kg |

Note:

1. The production capacity is based on bottles of 500ml. The actual capacity may be affected by the size and shape of customers' bottles.

2. BestCrown reserves the right to change these data according to the specific conditions.

Technical features:

1. The six-valve blowing valve group, three blowing and two recycling energy-saving solutions, enable customers to save energy by more than 25%.

2. Customer-customized full servo stretching system to meet various stretch ratios.

3. Complete and fully automatic CIP system to ensure the sanitary requirements of the inner surface of the equipment.

4. Positive pressure 100-level filling environment in the filling area.

5. Adopt PROFIBUS intelligent control technology to realize whole line control and intelligent data report, each Real-time monitoring of links.

6. Non-contact imported electronic flowmeter filling system and mechanical valve fixed liquid level filling valve to ensure accuracy.

7. Imported ion dust removal system to ensure the safety of packaging.

8. Customers can customize imported AROL capping system.

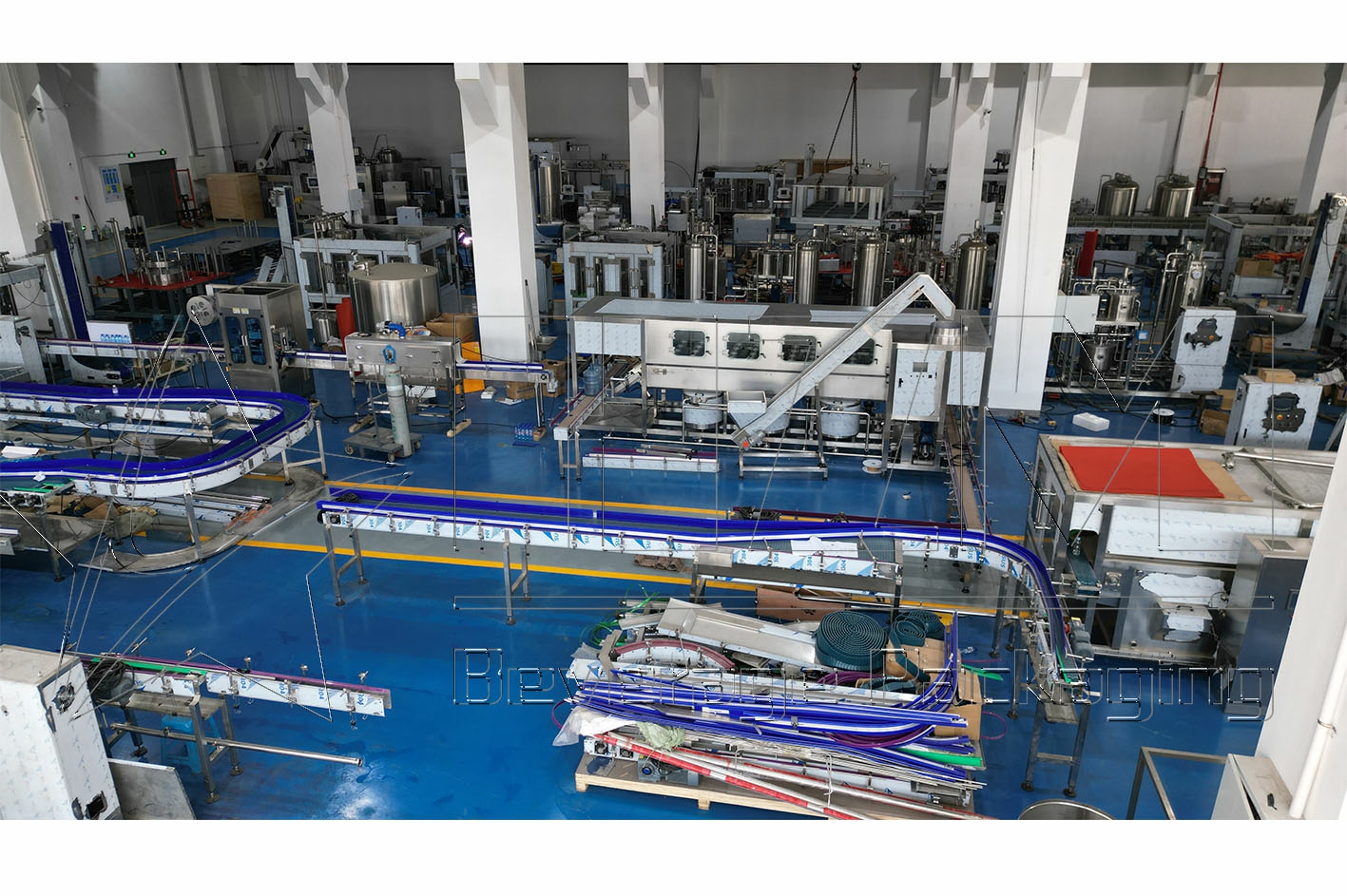

HZM Packaging Machinery Co., Ltd. is a comprehensive liquid beverage packaging solution provider specializing in design, manufacturing, sales and service. It has been deeply involved in the packaging machinery industry for nearly 10 years. Its service areas are widely used in beverages , dairy products, and condiments. It is one of the manufacturers with the highest level of technology and the most complete varieties of equipment for the production of liquid beverages in many packaging industries in China, such as alcohol, daily chemicals.

TAG: 1500 Bph Blowing Filling Capping Combiblock 1500 bph Blowing Filling Capping Combine 54000 bph glass bottle capping machine Blowing Filling Capping Combine

-

![Intelligent Control Head Blowing Filling Capping Combine]() Intelligent Control Head Blowing Filling Capping CombineJun , 09 /2023

Intelligent Control Head Blowing Filling Capping CombineJun , 09 /2023 -

![Pure Water 1500ml Blowing Filling Capping Combine]() Pure Water 1500ml Blowing Filling Capping CombineJun , 09 /2023

Pure Water 1500ml Blowing Filling Capping CombineJun , 09 /2023 -

![Energy Saving 24000 BPH PET Bottle Filling And Capping Machine]() Energy Saving 24000 BPH PET Bottle Filling And Capping MachineJun , 09 /2023

Energy Saving 24000 BPH PET Bottle Filling And Capping MachineJun , 09 /2023 -

![Automatic Pet 18000 Bph Bottled Water Production Machine Energy Saving]() Automatic Pet 18000 Bph Bottled Water Production Machine Energy SavingJun , 09 /2023

Automatic Pet 18000 Bph Bottled Water Production Machine Energy SavingJun , 09 /2023

Home /

Home /