Report: Establishing a Drinking Water Business

1. Overview of the Drinking Water Business

The demand for clean and safe drinking water continues to grow globally due to increased urbanization, health awareness, and concerns over water pollution. Starting a drinking water business involves producing, packaging, and distributing purified water in various forms such as bottled water, jarred water, or pouches.

2. Key Steps to Start a Drinking Water Business

2.1 Market Research and Business Planning

- Identify Target Market: Understand consumer demand, competitors, and pricing.

- Business Model: Decide whether to focus on bottled water, jarred water (5-gallon containers), or smaller pouches.

- Regulatory Compliance: Research local regulations and licenses required for water production and distribution.

2.2 Location and Facility Setup

- Location Requirements:

- Easy access to clean water sources.

- Adequate space for equipment, storage, and logistics.

- Facility Design:

- Separate areas for water treatment, packaging, and storage.

- Ensure compliance with health and safety standards.

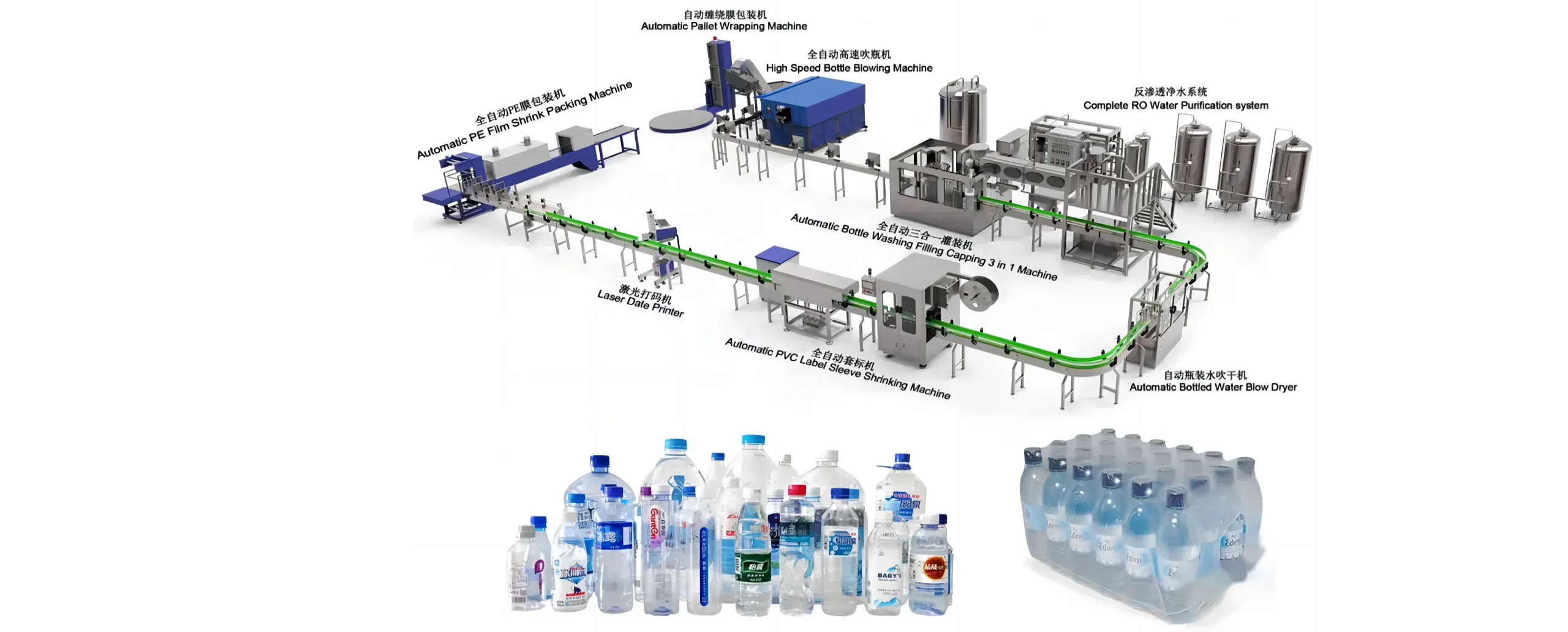

2.3 Equipment Procurement

A comprehensive drinking water production facility requires:

Water Treatment Equipment:

- Multi-stage filtration system (sand filter, carbon filter, etc.).

- Reverse osmosis (RO) system for removing dissolved impurities.

- UV sterilization and/or ozone generator for disinfection.

- Water softener (if required).

Packaging Equipment:

- Bottle blow molding machine (for producing PET bottles).

- Automatic washing, filling, and capping machines.

- Labeling machine and date printer.

- Shrink wrap or carton packing machine.

Auxiliary Equipment:

- Air compressor (for blow molding and other operations).

- Water storage tanks (stainless steel recommended).

- Conveyor systems.

- Backup generator to ensure uninterrupted production.

2.4 Licensing and Certification

- Obtain necessary licenses for food and beverage production.

- Certification from health authorities confirming water quality.

- Environmental clearance for waste management.

2.5 Branding and Marketing

- Develop a unique brand identity with a logo, tagline, and packaging design.

- Highlight health benefits, purity, and safety.

- Create marketing campaigns targeting retail outlets, supermarkets, and businesses.

2.6 Distribution and Logistics

- Partner with distributors or retailers.

- Establish a delivery system for bulk orders to businesses and households.

- Maintain a fleet of delivery vehicles for timely distribution.

3. Cost Estimation

- Initial Setup Cost: (Estimates will vary based on production scale.)

- Equipment: $50,000 – $200,000

- Facility Setup: $20,000 – $50,000

- Licensing and Certification: $5,000 – $10,000

- Marketing and Branding: $5,000 – $20,000

- Operational Costs:

- Raw materials (water, bottles, caps, labels): $10,000/month

- Utilities (electricity, water): $2,000/month

- Labor: $5,000/month

- Maintenance: $1,000/month

4. Challenges and Solutions

4.1 Challenges:

- High competition in the market.

- Strict regulatory requirements.

- Initial high capital investment.

4.2 Solutions:

- Differentiate the product through unique packaging and branding.

- Maintain high quality to build trust and loyalty.

- Gradually scale production to meet market demand.

5. Conclusion

HZM Machinery is a professional supplier of drinking water production equipment, offering turnkey solutions that include water treatment systems, bottling and packaging machinery, and comprehensive project support to ensure efficient and reliable operations.

TAG: Drinking Water Bottling Machine Drinking Water Production Line Drinking Water Treatment System

Home /

Home /