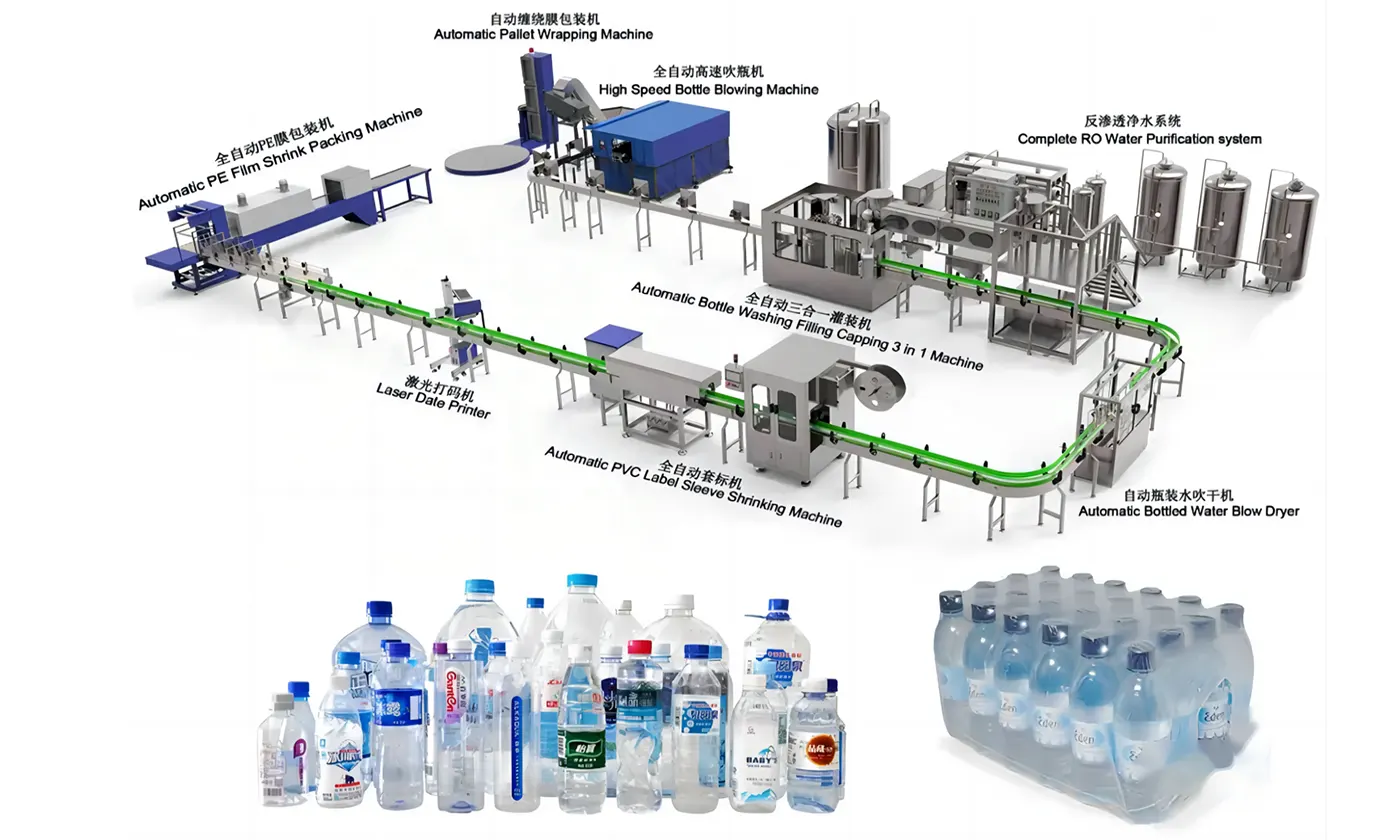

Packaged drinking water production line

Tip : You can obtain the price for individual equipment as well as solutions for the entire production line

Video

Product Overview

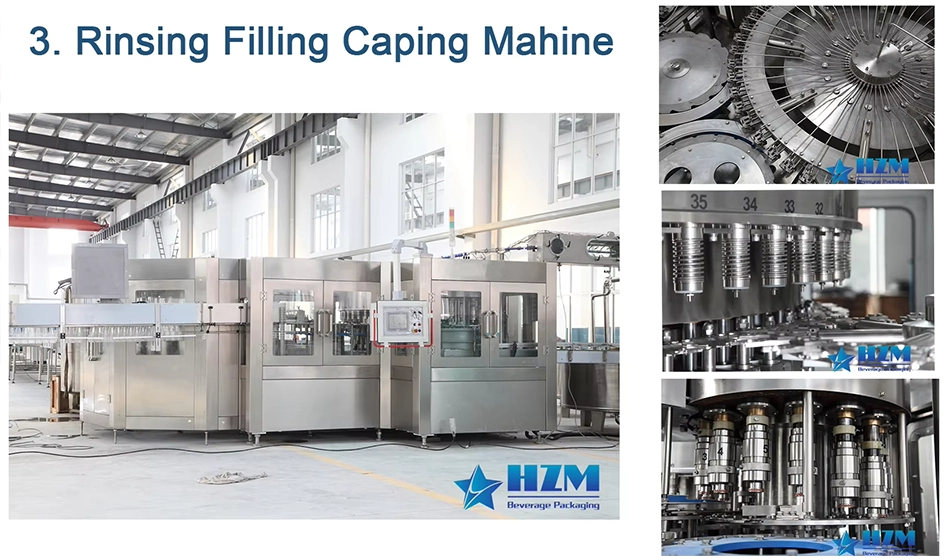

1. This water filling machine has a compact structure, perfect control system, easy to operate and highly automated. 2. Only by changing the star-wheel, arch board can realize fill bottle shape change.

3. The parts contact with product is made of quality SUS316/304, anti-corrosive, and easy to clean.

4. Rapid flow, highly filling precision, nicety liquid level without any liquid loss to satisfy the filling process demand.

5. The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

6. This water filling machine has a high efficient cap arranging system, perfect cap feeding with self-control and self-protection device.

7. The water filling machine adopts perfect overload protective device can ensure the operator and machine safety.

8. The control system has many functions, such as control producing speed, cap shortage detection, bottle block automatic stop and production counting etc.

9. The main electric and air-drive components are world famous brand products.

10. All control is advanced touch-screen operation and realize people-computer dialogue operation.

Device parameters

| Model | DXGF24-24-8 | DXGF32-32-8 | DXGF40-40-10 | DXGF50-50-12 | DXGF60-60-15 |

| (for 500ml) | 8,000BPH | 12,000BPH | 15,000BPH | 18,000BPH | 21,000BPH |

| Bottle diameter | 50~110mm | ||||

| Bottle height | 160~310mm | ||||

| Air source pressure | 0.7MPa | ||||

| Main motor power |

3.0KW | 4.0KW | 7.5KW | 7.5KW | 11KW |

| Dimension | 2800*2230*2700 | 3550*2650*2700 | 4360*3300*2700 | 4720*3545*2700 | 5770*5288*2700 |

Complete Production Line Solution

Water treatment system

CO2 mixes fully

Rinsing Filling Caping Mahine

Labeling Packing Mahine

Home /

Home /