Overview of Packaging Machine Types and Classification Methods

There are various types of packaging machines, and there are many methods for their classification. Different perspectives can lead to multiple classifications. Based on the product state, there are liquid, solid, and granular packaging machines. Based on the packaging function, there are machines for inner packaging and outer packaging. When classified by industry, there are packaging machines for food, daily chemicals, textiles, and others. According to the packaging stations, there are single-station and multi-station packaging machines. In terms of automation level, there are semi-automatic and fully automatic packaging machines, among others.

There are many classification methods for packaging machines, each with its own characteristics and applicability, but all have their limitations. From an international perspective on packaging machinery, a more scientific classification method is based on their primary functions, which captures the essence of things. The basic classifications are as follows:

(1) Filling Machines

Filling machines are used to pack a certain quantity of products into various containers. They can be further categorized as follows:

① Volumetric Filling Machines: Including cup filling, tube filling, piston filling, level filling, screw filling, and timed filling machines.

② Weight-based Filling Machines: Including intermittent weighing, continuous weighing, and weighing-centrifugal fractionating filling machines.

③ Counting Filling Machines: Including single-piece and multi-piece counting filling machines.

(2) Sealing Machines

Sealing machines are used to seal containers filled with packaging materials. They can be classified as follows:

① Sealers without sealing material: Including heat sealing, cold sealing, melt welding, interlocking, and folding sealers.

② Sealers with sealing material: Including rotary, crimping, edge rolling, and compression sealers.

③ Sealers with auxiliary sealing material: Including tape sealing, adhesive sealing, nail sealing, strapping, and stitching sealers.

(3) Wrapping Machines

Wrapping machines use flexible packaging materials to fully or partially wrap the packaged items. They can be further categorized as follows:

① Full Wrapping Machines: Including twist wrapping, covering, body-fitting, and seam wrapping machines.

② Semi Wrapping Machines: Including folding, shrink, stretch, and winding wrapping machines.

(4) Multi-function Packaging Machines

These packaging machines have two or more functions. The main types include:

① Fully Automatic Pillow-type Packaging Machine.

② Filling and Sealing Machines: These machines have filling and sealing functions.

③ Forming, Filling, and Sealing Machines: These machines have forming, filling, and sealing functions. The forming methods include bag forming, bottle forming, box forming, blister forming, and melt molding.

④ Shrink Box Sealers: These machines can simultaneously seal both the top and bottom faces of a box. The boxes can be placed horizontally or vertically during sealing.

Furthermore, there are other classification methods based on the position and number of adhesive tapes used for sealing.

(5) According to Specialization:

① General Carton Sealers: These can be adjusted to fit various sizes of cartons and have a wide range of applications.

② Specialized Carton Sealers: They can only seal a specific size of carton, but they operate at high speeds and are suitable for mass carton sealing.

③ Random Carton Sealers: These can automatically adjust within a specified size range to accommodate different carton sizes, and they are highly automated.

Forming-Filling-Sealing Packaging Machine: This is a multi-functional packaging machine (see Figure 1). The product enters the top of the machine, and the metering unit fills a predetermined amount of the product into the material channel. The roll of packaging material passes through the outer wall of the material channel and is shaped into a tube by the forming device, and then the longitudinal sealer seals it firmly. The horizontal sealer completes the top sealing of the packaging bag and the bottom sealing of the next bag, creating two welds. The product is discharged into the material channel, and after the bottom sealing is completed, it can be directly filled into the bag. Then, it moves to the next station for top sealing, and a cutter is used to cut and complete the packaging process.

The roll of packaging material can be single-layer or composite. Single-layer materials include moisture-proof glass paper, polyethylene, polypropylene, high-density polyethylene, while composite materials include stretch polypropylene/polyethylene, polyethylene/glass paper/aluminum foil, and others. Additionally, heat-sealable materials are used. The sealing types include pillow-type sealing, three-side sealing, and four-side sealing.

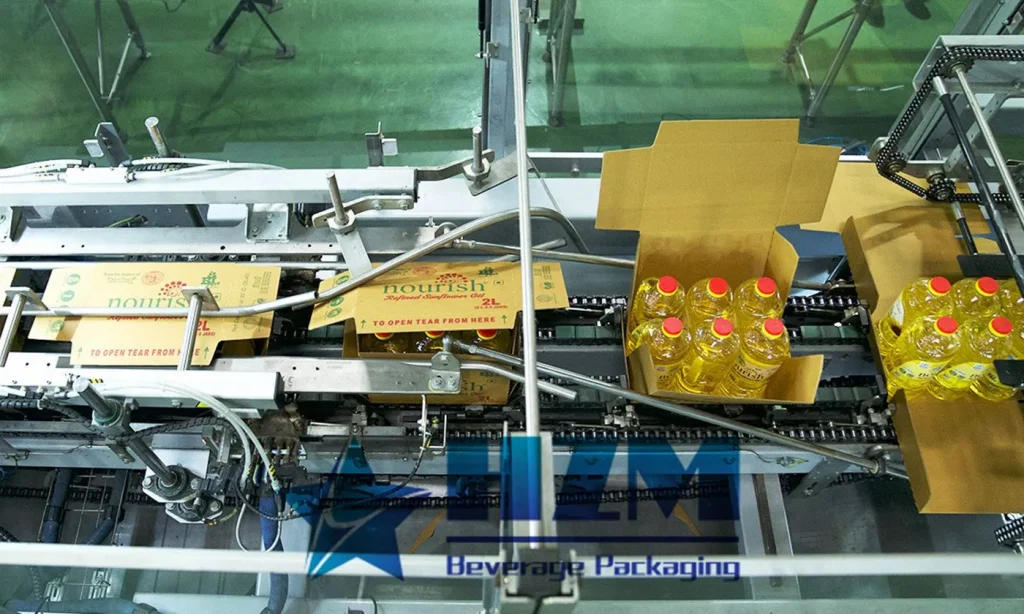

Bottling and Boxing Packaging Line: The bottling machine is used for product sales packaging. It fills a measured quantity of the product into boxes and closes or seals the box opening. The boxing machine is used for transportation packaging. It arranges the sales-packed products in a certain order and quantity into boxes and closes or seals the box opening. Both the bottling and boxing machines have functions such as container forming (or opening containers), metering, filling, and sealing. Figure 2 shows the flowchart of the bottling, boxing, and boxing packaging line. The hose container is positioned, filled, and sealed by the filling machine, then sent to the boxing machine. The boxing machine first forms the box and wraps the hose with liner paper before pushing it into the box and closing the box opening. The small boxes are stacked in the big boxing machine after being transported by a conveyor. Once the predetermined quantity is stacked, the big boxes are wrapped to form containers with the small boxes placed inside, and then glue is applied for sealing. The large boxes are transported to the boxing machine, where they are stacked and, once reaching the predetermined quantity, put into open boxes. After boxing, the box covers are sealed with glue by the box sealing and pasting machine, and the box flaps are taped or tied firmly using a bundling machine.

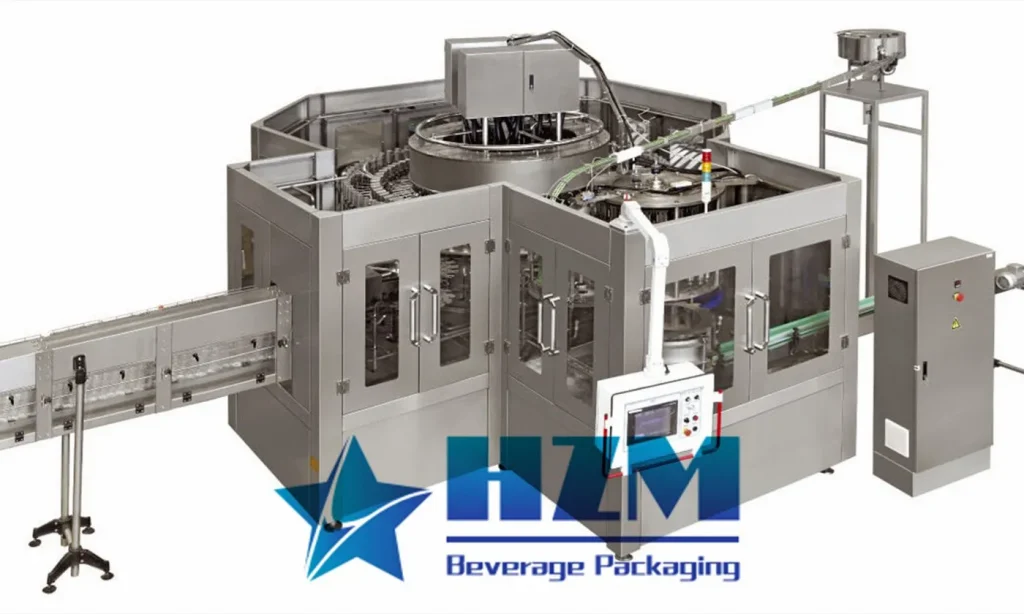

Liquid Filling Machine and Its Assembly Line: Filling machines are classified into atmospheric filling machines, pressure filling machines, and vacuum filling machines based on the filling principle.

① Atmospheric Filling Machine: It fills the liquid under atmospheric pressure relying on its own weight. This type of filling machine can be further divided into timed filling and constant volume filling, and it is suitable for filling low-viscosity and non-gaseous liquids such as milk and wine.

② Pressure Filling Machine: It fills the liquid under pressure higher than atmospheric pressure and can be divided into two types: one with equal pressure between the liquid in the storage tank and the bottle (known as isobaric filling), and the other with higher pressure in the storage tank, leading to liquid flowing into the bottle due to pressure difference (commonly used in high-speed production lines). Pressure filling machines are suitable for filling liquids with gas, such as beer, soda, and champagne.

③ Vacuum Filling Machine: It fills the liquid under pressure lower than atmospheric pressure inside the bottle. This type of filling machine has a simple structure, high efficiency, and a wide range of applications for materials with varying viscosities, such as oils, syrups, and fruit wines.

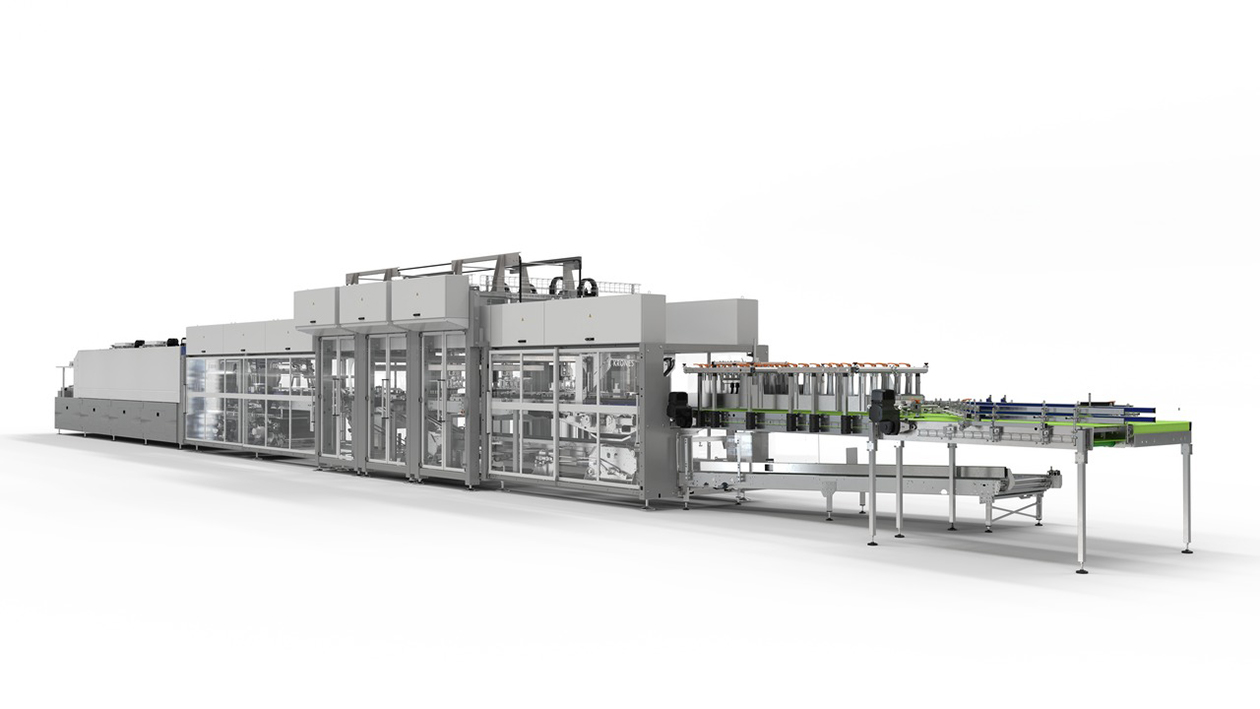

Figure 3 shows the flowchart of the liquid filling process. Empty bottles in boxes are stacked on pallets and conveyed to the depalletizer, where the pallets are unloaded one by one. The boxes are sent to the unboxing machine, which removes the empty bottles from the boxes. The empty boxes are then sent to the washing machine for cleaning before being conveyed to the vicinity of the boxing machine to receive the filled beverages. The empty bottles taken out by the unboxing machine are sent to the bottle washer for disinfection and cleaning, and after passing the bottle inspector, they are filled and capped by the filling and capping machine. The beverages are filled into the bottles by the filling machine. The bottles filled with beverages are capped and sealed by the capping machine and then sent to the labeling machine for labeling. After labeling, the bottles are sent to the boxing machine to be placed in boxes, which are subsequently stacked by the palletizer and sent to the warehouse.

While the processes for various beverage bottles are similar, the filling and capping machines used may vary based on the nature of the beverages. For example, a beer filling assembly line would include a suitable filling and capping machine as well as a pasteurization machine. The choice of the sealing machine depends on the type of caps used, such as crown caps, screw caps, or stoppers.

TAG: filling machines Packaging machine

-

![What should be paid attention to when purchasing food-specific filling machines?]() What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023

What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023 -

![Five Tips for Choosing the Right Packaging Machine for Your Business]() Five Tips for Choosing the Right Packaging Machine for Your BusinessApr , 24 /2023

Five Tips for Choosing the Right Packaging Machine for Your BusinessApr , 24 /2023 -

![200-500ml Ultra-Clean Filling Machine]() 200-500ml Ultra-Clean Filling MachineJun , 09 /2023

200-500ml Ultra-Clean Filling MachineJun , 09 /2023 -

![Filling Machine, Classification, Workflow, Instructions for Use, Procurement]() Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023

Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023 -

![Revolutionizing Beverage Production: The Ultimate Beverage Filling Machine]() Revolutionizing Beverage Production: The Ultimate Beverage Filling MachineJun , 27 /2023

Revolutionizing Beverage Production: The Ultimate Beverage Filling MachineJun , 27 /2023 -

![Design and Electrical Control of Fully Automatic Carton Packaging Machine]() Design and Electrical Control of Fully Automatic Carton Packaging MachineAug , 15 /2023

Design and Electrical Control of Fully Automatic Carton Packaging MachineAug , 15 /2023 -

![How much does a bottling machine cost]() How much does a bottling machine costAug , 25 /2023

How much does a bottling machine costAug , 25 /2023 -

![What is a Beverage Packaging Machine?]() What is a Beverage Packaging Machine?Aug , 25 /2023

What is a Beverage Packaging Machine?Aug , 25 /2023