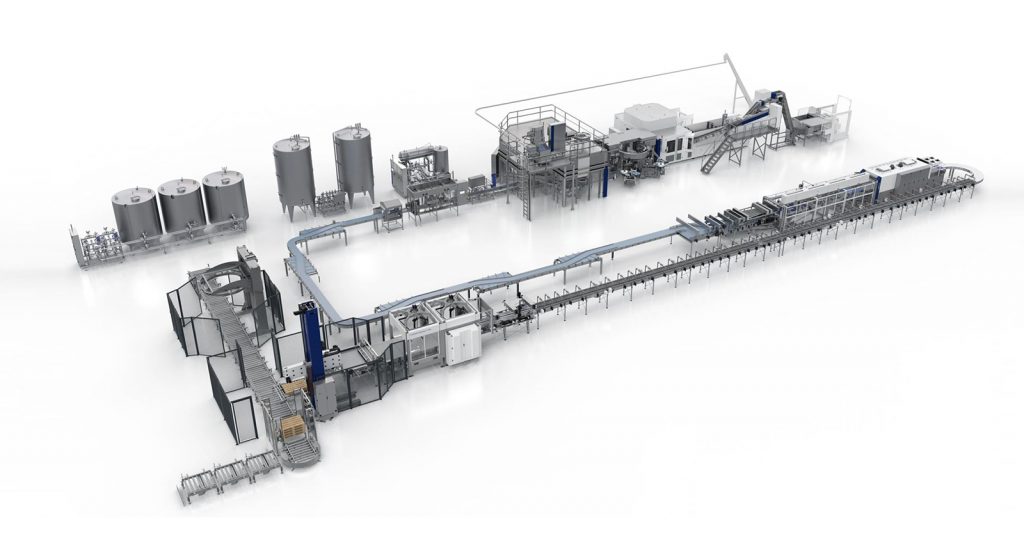

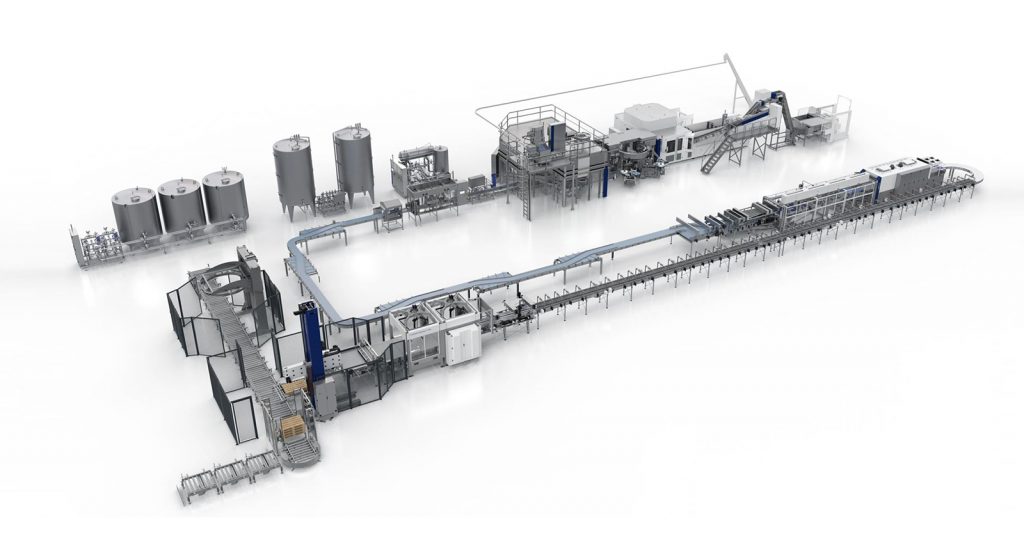

Comprehensive Equipment Plan for Mineral Water Production

1. Introduction

A well-designed mineral water production line ensures high efficiency, product quality, and eco-friendliness. Proper equipment selection and workflow planning are essential for smooth operations and consistent output.

2. Essential Equipment

- Water Treatment Systems – Filters, UV sterilizers, and reverse osmosis units for water purification.

- Filling & Capping Machines – Automated systems for precise bottling, capping, and labeling.

- Packaging Equipment – Case packers and robotic systems for secure packaging.

- Quality Control Tools – Automated inspection systems for accuracy in filling and packaging.

- Energy-Efficient Solutions – Equipment designed to minimize power consumption and environmental impact.

3. Equipment Selection & Procurement

- Supplier Evaluation – Choose reputable suppliers based on cost, reliability, and after-sales support.

- Budgeting – Allocate funds for equipment, installation, and logistics.

- Procurement Timeline – Plan timely delivery and installation to avoid project delays.

4. Installation & Commissioning

- Professional Setup – Engage skilled technicians for proper equipment installation.

- Operator Training – Train staff on equipment operation and maintenance.

- Testing & Quality Check – Conduct thorough tests to ensure compliance with industry standards.

5. Production Workflow

- Water Treatment – Purify water to meet safety and regulatory standards.

- Filling & Packaging – Automate bottling and packaging with real-time quality monitoring.

- Quality Assurance – Implement regular testing for consistent product quality.

6. Environmental Sustainability

- Wastewater Treatment – Install systems to reduce environmental impact.

- Energy Efficiency – Utilize energy-saving equipment and production practices.

- Eco-Friendly Packaging – Use recyclable or biodegradable materials.

7. Financial Planning

- Cost Estimation – Cover equipment, labor, and material expenses.

- Revenue Projections – Forecast sales and profitability.

- ROI Analysis – Assess financial viability and expected returns.

8. Risk Management

- Market Risks – Monitor demand fluctuations and competition.

- Quality Risks – Address equipment failures and product deviations.

- Regulatory Compliance – Stay updated on legal and industry standards.

9. Timeline & Milestones

Develop a structured project timeline with key milestones to track progress and ensure timely execution.

10. Conclusion

This plan provides a structured approach to establishing a high-quality, efficient, and sustainable mineral water production line, ensuring compliance with industry standards while maximizing profitability.

TAG: filling machines Mineral Water Production Line

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?