Mineral Water Plant Production Line Cost

The cost plan for a mineral water plant production line can vary based on several factors, including production scale, location, equipment, and technology choices.

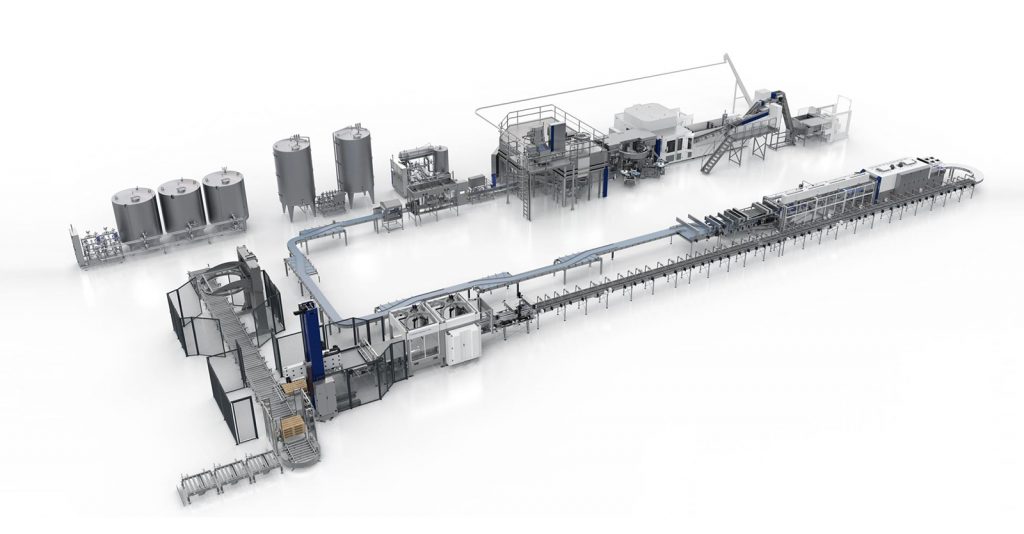

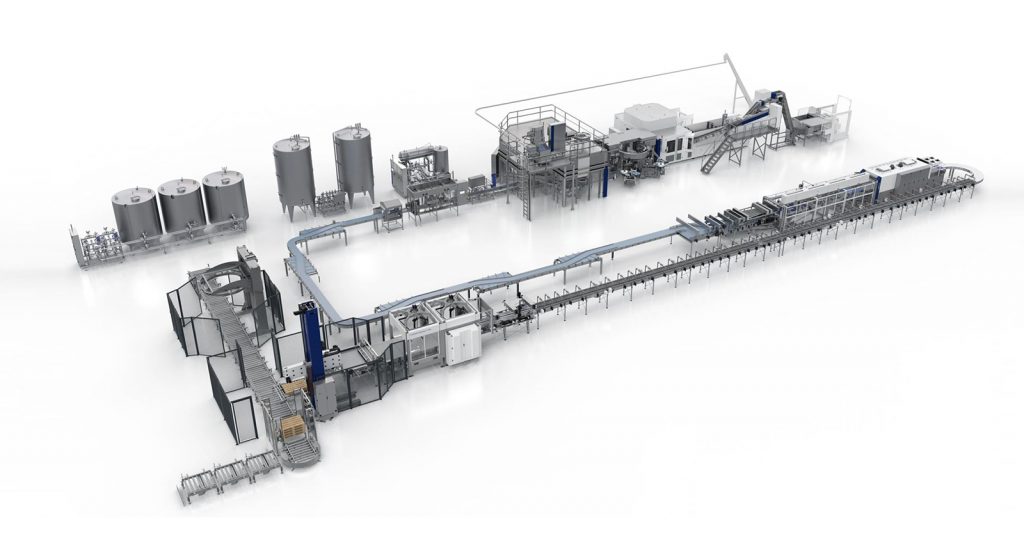

We are a comprehensive supplier of mineral water plant production equipment, specializing in the development, manufacturing, and sales of a range of equipment related to mineral water production. We provide complete mineral water production lines, including water treatment systems, mineral water filling machines, capping machines, automatic labeling machines, packaging machines, conveyors, palletizers, and more. We can offer turnkey projects and have a team of professional after-sales service engineers. Currently, our equipment is exported to over 30 regions and countries worldwide. We welcome more friends to discuss and inquire.

Here is a summary of the cost plan for a mineral water plant production line that we offer, for reference. The actual costs may require a detailed business plan and cost analysis:

- Building and Land Costs:

- Land purchase or leasing expenses.

- Building construction or renovation costs.

- Infrastructure, electricity, water, and gas supply expenses.

- Equipment Costs:

- Water treatment equipment, such as reverse osmosis systems, filters, and disinfection equipment.

- Mineral water filling and packaging equipment.

- Storage tanks, conveyors, etc.

- Quality control equipment and laboratory tools.

- Raw Material Costs:

- Costs associated with sourcing water.

- Packaging material costs, including bottles, labels, caps, and packaging materials.

- Labor Costs:

- Salaries and benefits for operators, technicians, and maintenance personnel.

- The number of staff required for the production line.

- Utility and Permit Costs:

- Expenses for permits, including health department approvals and water quality testing.

- Energy Costs:

- Electricity and gas costs for equipment operation and heating/cooling.

- Packaging and Distribution Costs:

- Expenses for packaging materials, truck transportation, and distribution channels.

- Operating and Maintenance Costs:

- Regular maintenance, repairs, and equipment replacement costs.

- Marketing and Advertising Costs:

- Expenses for promotion, advertising, and marketing campaigns.

- Ongoing Training Costs:

- Costs for providing necessary training and education for employees.

- Wastewater Treatment and Waste Management Costs:

- Expenses related to wastewater treatment and waste disposal.

- Miscellaneous Expenses:

- Budget for unforeseen or miscellaneous expenditures.

- Interest Expenses:

- Consider interest payments if loans are needed to fund the project.

- Working Capital:

- Capital required for daily operating expenses, including raw materials, salaries, and utilities.

- Insurance Costs:

- Expenses for insurance to protect the business and assets.

This is a general estimate, and specific costs will vary depending on project scale, location, and other factors. Before starting the project, you should undertake a detailed business plan, including cost analysis, and consult with industry experts and equipment suppliers to obtain a more accurate estimate of the cost of a mineral water plant production line.

TAG: Mineral Water Filling Machine Mineral Water Packing Machine Mineral Water Production Line

-

![How Much Does a Mineral Water Production Line Cost?]() How Much Does a Mineral Water Production Line Cost?Sep , 14 /2023

How Much Does a Mineral Water Production Line Cost?Sep , 14 /2023 -

![Comprehensive Equipment Plan for Mineral Water Production]() Comprehensive Equipment Plan for Mineral Water ProductionSep , 18 /2023

Comprehensive Equipment Plan for Mineral Water ProductionSep , 18 /2023 -

![Mineral Water Plant Production Equipment Solutions And Prices]() Mineral Water Plant Production Equipment Solutions And PricesOct , 29 /2023

Mineral Water Plant Production Equipment Solutions And PricesOct , 29 /2023 -

![Which machines are required for mineral water plant?]() Which machines are required for mineral water plant?Nov , 08 /2023

Which machines are required for mineral water plant?Nov , 08 /2023 -

![HZM Machinery Offers Turnkey Projects for Mineral Water Plants]() HZM Machinery Offers Turnkey Projects for Mineral Water PlantsNov , 17 /2023

HZM Machinery Offers Turnkey Projects for Mineral Water PlantsNov , 17 /2023 -

![Optimized Overview of the Mineral Water Production Line Process and Equipment]() Optimized Overview of the Mineral Water Production Line Process and EquipmentNov , 28 /2023

Optimized Overview of the Mineral Water Production Line Process and EquipmentNov , 28 /2023 -

![How much does a complete set of mineral water production line equipment cost?]() How much does a complete set of mineral water production line equipment cost?Dec , 18 /2023

How much does a complete set of mineral water production line equipment cost?Dec , 18 /2023

Home /

Home /