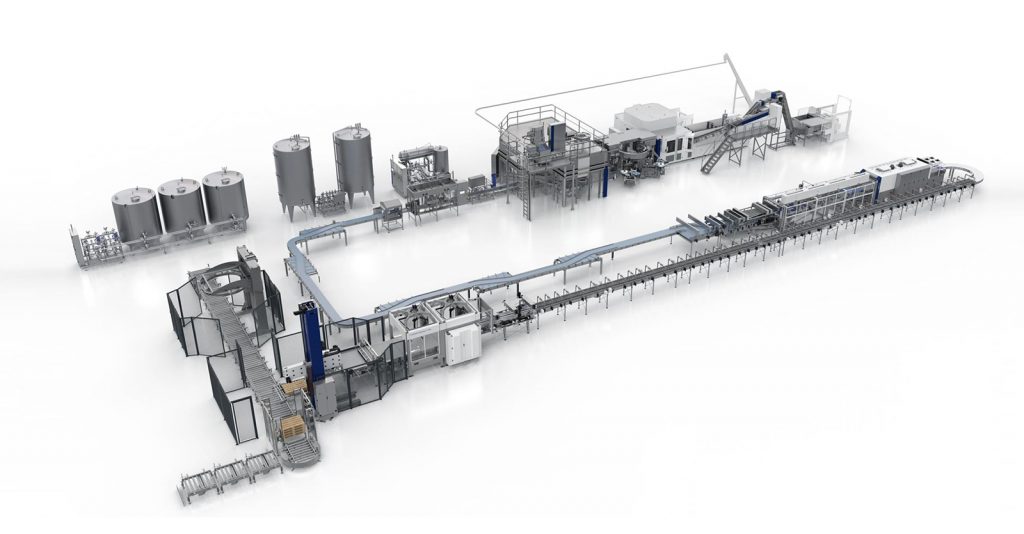

Mineral Water Bottling Production Line Process

With the improvement of living standards, mineral water has become the preferred choice for daily drinking water. In the market, most mineral water is sold in barrels to ensure better quality and safety. So, what is the process of a mineral water bottling production line? Let's introduce it step by step.

Step 1: Construction and Development

Before the production of any mineral water bottling production line, it is necessary to carry out on-site construction and development according to the construction plan. This step mainly involves determining the location and functions of major infrastructure such as offices, production plants, warehouses, power distribution rooms, and gas stations. In addition, the production line needs to be equipped with corresponding equipment, such as air filtration equipment, mineral water pretreatment equipment, packaging machines, and filling lines.

Step 2: Raw Material Preparation

Before producing mineral water, various raw materials need to be prepared. This includes the water source from the mineral water's origin, mineral water treatment agents, disinfectants, etc. These raw materials need to undergo professional processing and disinfection to ensure the safety of water quality before entering the filling production line.

Step 3: Water Source Treatment

Water source treatment is one of the core steps in a mineral water bottling production line, aiming to ensure the safety and hygiene of water quality. During the process of treating the water source, impurities, bacteria, and other harmful substances in the water need to be removed through methods such as filtration, sedimentation, and membrane separation, in order to obtain clean and safe water sources. This ensures that the quality of the final bottled mineral water meets the standards.

Step 4: Mineral Water Disinfection

After the water source is treated, the mineral water needs to be disinfected. The purpose of disinfection is to kill bacteria, viruses, microorganisms, and other harmful substances in the water. Common disinfection methods include ultraviolet sterilization and high-temperature disinfection.

Step 5: Packaging and Filling

Mineral water packaging and filling are the final steps of the entire production line. In this step, suitable filling lines and packaging materials, such as barrels or bottles, need to be selected for automatic packaging and filling according to the product specifications. During the packaging and filling process, strict control and inspection of the packaging's appearance, quality, and other indicators are necessary to ensure the product quality meets the standards.

In summary, the process of a mineral water bottling production line needs to be designed, constructed, and produced according to standardized, professional, and scientific requirements. Only by ensuring strict control at each step can the quality and safety of mineral water be guaranteed.

TAG: 5 Gallon Water Filling Line Water Bottle Filling Machine Water Bottling Machine Water Filling Line

-

![12000BPH Pure Water Filling Line Debugging Successfully Completed]() 12000BPH Pure Water Filling Line Debugging Successfully CompletedMar , 24 /2023

12000BPH Pure Water Filling Line Debugging Successfully CompletedMar , 24 /2023 -

![Here are five things to consider for maintaining a fully automated mineral water production line]() Here are five things to consider for maintaining a fully automated mineral water production lineApr , 20 /2023

Here are five things to consider for maintaining a fully automated mineral water production lineApr , 20 /2023 -

![HZM: Your Reliable Supplier for 5 Gallon Water Filling Line]() HZM: Your Reliable Supplier for 5 Gallon Water Filling LineJun , 02 /2023

HZM: Your Reliable Supplier for 5 Gallon Water Filling LineJun , 02 /2023 -

![5 Gallon Water Filling Line: Pricing and Procurement Considerations]() 5 Gallon Water Filling Line: Pricing and Procurement ConsiderationsJun , 03 /2023

5 Gallon Water Filling Line: Pricing and Procurement ConsiderationsJun , 03 /2023 -

![HZM Water Filling Line: Your Reliable Supplier for Complete Equipment Solutions]() HZM Water Filling Line: Your Reliable Supplier for Complete Equipment SolutionsJun , 06 /2023

HZM Water Filling Line: Your Reliable Supplier for Complete Equipment SolutionsJun , 06 /2023 -

![HZM Mineral Water Production Line Equipment Manufacturer]() HZM Mineral Water Production Line Equipment ManufacturerJun , 06 /2023

HZM Mineral Water Production Line Equipment ManufacturerJun , 06 /2023 -

![Stainless Steel 200ml Automatic Water Bottle Filling System]() Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023

Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023 -

![5 Gallon Water Bottle Packing Machine]() 5 Gallon Water Bottle Packing MachineJun , 09 /2023

5 Gallon Water Bottle Packing MachineJun , 09 /2023 -

![Bottled Water Production Line:5-gallon]() Bottled Water Production Line:5-gallonJun , 23 /2023

Bottled Water Production Line:5-gallonJun , 23 /2023 -

![In-Depth Analysis of the Water Bottle Filling Machine Market]() In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023

In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023 -

![Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling Line]() Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023

Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023 -

![How much does a bottling machine cost]() How much does a bottling machine costAug , 25 /2023

How much does a bottling machine costAug , 25 /2023 -

![Bottled water production process PDF]() Bottled water production process PDFSep , 18 /2023

Bottled water production process PDFSep , 18 /2023 -

![Mineral Water Machine Price in Pakistan: A Comprehensive Guide]() Mineral Water Machine Price in Pakistan: A Comprehensive GuideSep , 30 /2023

Mineral Water Machine Price in Pakistan: A Comprehensive GuideSep , 30 /2023 -

![Mineral Water Production Cost]() Mineral Water Production CostOct , 01 /2023

Mineral Water Production CostOct , 01 /2023 -

![Common Faults in 5-Gallon Drum Filling Lines and Their Solutions]() Common Faults in 5-Gallon Drum Filling Lines and Their SolutionsOct , 04 /2023

Common Faults in 5-Gallon Drum Filling Lines and Their SolutionsOct , 04 /2023

Home /

Home /