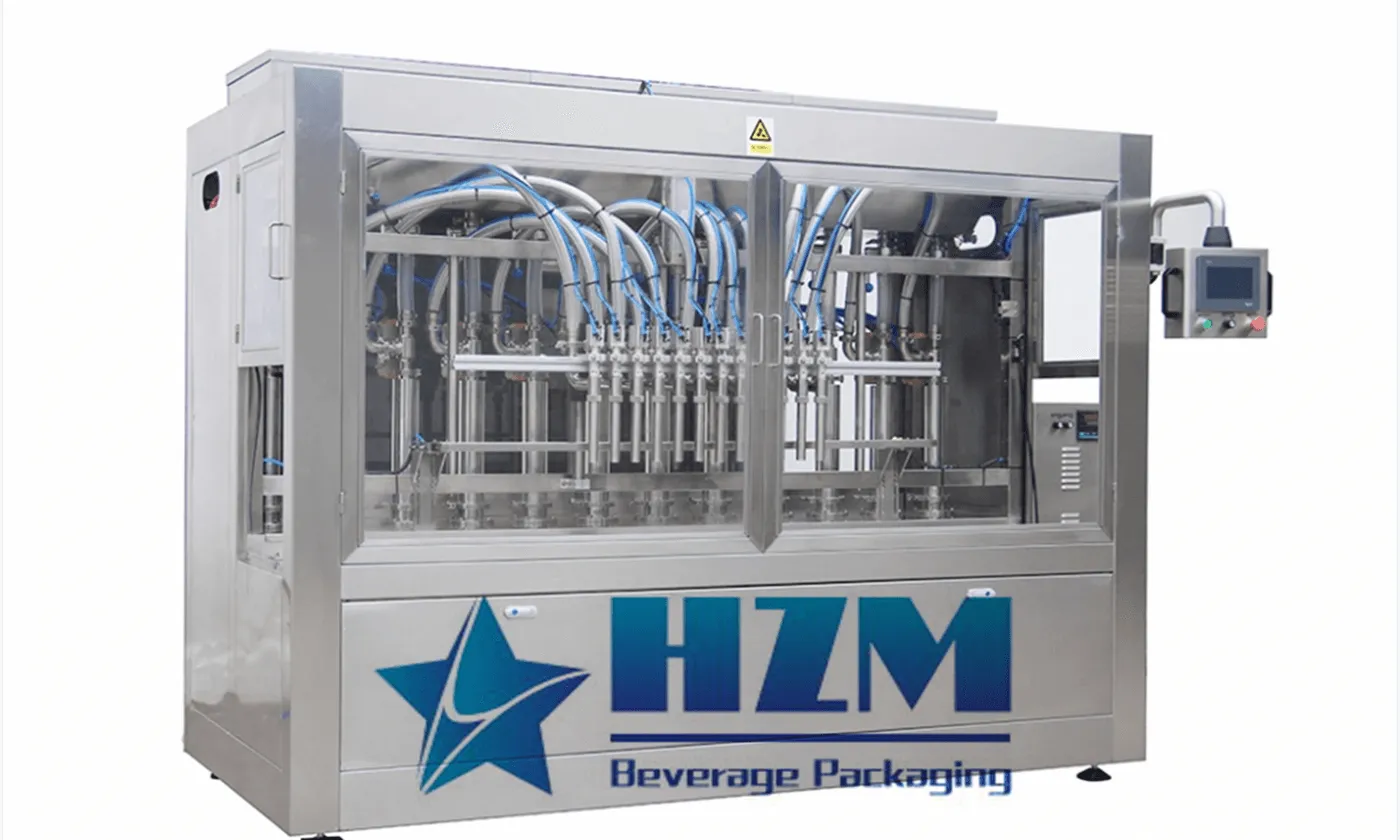

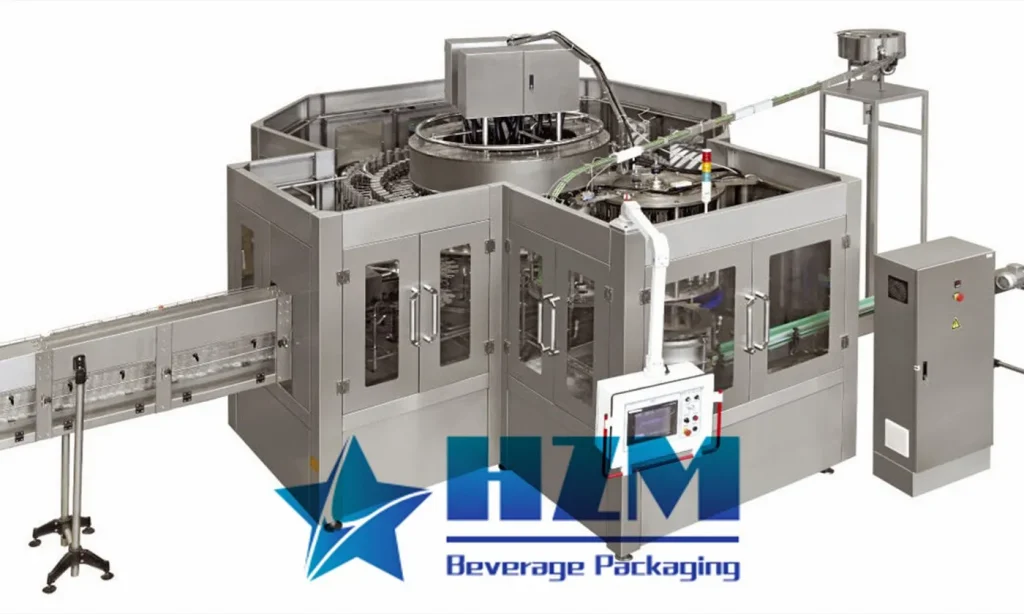

Manufacturer of edible oil filling machines offers stable and user-friendly equipment

For manufacturers of edible oil filling machines, the stability and practicality of equipment are paramount, alongside good value for money. Here's an introduction to the structure of the equipment provided by edible oil filling machine manufacturers. Please read carefully!

Manufacturers of edible oil filling machines often employ vacuum filling machines. This method keeps the material tank at atmospheric pressure. During filling, air is evacuated from the bottle to create a vacuum. When a certain level of vacuum is reached, the liquid flows into the bottle from the supply tank due to the pressure difference, completing the filling process. This method is mainly used for filling non-gaseous liquids. It automatically stops filling when there's a bottle leakage, reducing losses. However, for some aromatic liquids, there may be a slight loss of fragrance due to vacuum filling. Additionally, vacuum filling has strict requirements for bottle specifications because the quantity is determined by the depth of the filling nozzle into the bottle, directly affecting the accuracy of quantification. Nevertheless, due to its ease of adjustment, it is still widely used.

Equipment from manufacturers of edible oil filling machines typically consists of filling systems, bottle in/out mechanisms, bottle lifting mechanisms, workbenches, and transmission systems. It's used for filling non-gaseous liquids and usually employs a rotary design. Under the action of the transmission system, the shaft drives the turntable and the measuring cup to rotate together. The liquid flows into the measuring cup from the material tank through the pipeline due to its own weight. Under the action of the cam, the bottle carrier lifts the bottles. When the bottle mouth presses against the cap plate and rises, the spring compresses, causing the slide valve to slide upward in the movable measuring cup's inner hole. As the shaft rotates, the properly measured cup moves away from the feed pipe and enters the filling position. When the slide valve opens the liquid hole and the liquid flows into the bottle, the gas inside the bottle is discharged through the four small grooves on the lower surface of the cap plate, completing the filling task of one bottle. With the rotation of the turntable, the measuring cup enters below sequentially to complete the quantification. When it moves away from the quantification position and enters the filling position, it starts filling again, continuously and repeatedly.

The above is the internal structure and function of edible oil filling machines. Please use the equipment according to the instructions. If you're interested in purchasing products such as Jiangang automatic filling machines, edible oil filling machines, beverage filling machines, etc., please contact us for quotations and specifications.

TAG: Edible Oil Filling Machine Oil Filling Machine

-

![How to Choose the Best Fully Automatic Edible Oil Filling Machine]() How to Choose the Best Fully Automatic Edible Oil Filling MachineMay , 04 /2023

How to Choose the Best Fully Automatic Edible Oil Filling MachineMay , 04 /2023 -

![Filling Machine, Classification, Workflow, Instructions for Use, Procurement]() Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023

Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023 -

![How much does an edible oil filling machine cost per unit, and how to choose the right one?]() How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023

How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023 -

![Edible Oil Bottle Filling Machine: Manufacturers and Pricing]() Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023

Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023 -

![Edible Oil Filling Machine Manual]() Edible Oil Filling Machine ManualOct , 12 /2023

Edible Oil Filling Machine ManualOct , 12 /2023 -

![Operation Procedure and Precautions for Edible Oil Filling Machine]() Operation Procedure and Precautions for Edible Oil Filling MachineOct , 18 /2023

Operation Procedure and Precautions for Edible Oil Filling MachineOct , 18 /2023 -

![What is an edible oil filling machine?]() What is an edible oil filling machine?Oct , 22 /2023

What is an edible oil filling machine?Oct , 22 /2023 -

![What equipment does the edible oil filling production line include?]() What equipment does the edible oil filling production line include?Oct , 25 /2023

What equipment does the edible oil filling production line include?Oct , 25 /2023

Home /

Home /