Large-Scale Beverage Filling Line: Enhancing Efficiency and Innovation in Beverage

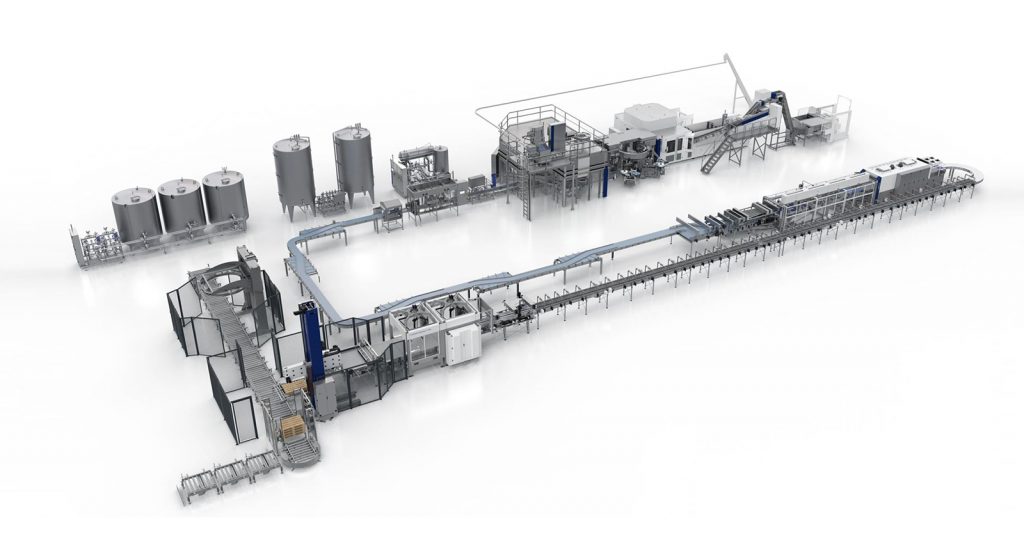

The large-scale beverage filling line is a highly automated equipment system widely used in mass beverage production. Comprised of multiple devices, each with its specific role, it ensures efficient and precise filling and packaging of beverages. As a manufacturer of large-scale beverage filling lines, HZM Machinery has established a strong reputation in the market.

Applications:

HZM Machinery's large-scale beverage filling line is suitable for various enterprises engaged in mass beverage production, including beverage manufacturers, bottled beverage companies, energy drink manufacturers, soda production companies, and more. It provides efficient and reliable production solutions to meet the increasing market demands.

Equipment Components and Responsibilities:

The large-scale beverage filling line consists of several key components:

- Conveying System: Transports empty bottles or pre-packaged beverage containers to the filling area, ensuring continuous operation of the production line.

- Cleaning and Disinfection System: Cleans and disinfects the beverage containers, guaranteeing product hygiene and safety.

- Filling System: Accurately fills the beverage containers with the designated volume, ensuring consistency and quality for each product.

- Sealing and Packaging System: After filling, seals and packages the beverage containers, ensuring long-term product preservation and transportation.

- Inspection and Quality Control System: Conducts inspections on filled beverage containers to ensure compliance with quality standards and eliminates defective products.

Price and Brand:

HZM Machinery is a professional manufacturer committed to providing high-quality large-scale beverage filling lines. We prioritize product performance and stability while offering customized solutions to meet the unique requirements of different enterprises. Our large-scale beverage filling lines are competitively priced, reliable, and enjoy a strong reputation in the market.

You can contact us anytime for a quote, You can obtain the price for individual equipment as well as solutions for the entire production line

Advantages and Disadvantages of Large-Scale Beverage Filling Lines

Advantages:

- High Production Capacity: Large-scale beverage filling lines offer high production capacity to meet the demands of mass beverage production, thereby improving production efficiency.

- High Level of Automation: The equipment system is highly automated, reducing labor input and enhancing production efficiency and consistency.

Disadvantages:

- High Investment Cost: Large-scale beverage filling lines require significant initial investment, which may pose financial challenges for start-ups or smaller-scale enterprises.

- Space Requirements: Large-scale beverage filling lines typically require ample production space, which may pose limitations for enterprises with limited space.

By choosing HZM Machinery's large-scale beverage filling line, you will acquire an efficient and reliable equipment system that brings innovation and competitive advantages to your beverage production. Whether you are a large-scale beverage production enterprise or aiming to expand your production capacity, HZM Machinery can provide tailored solutions. Feel free to contact us to learn more about our large-scale beverage filling lines, and let us contribute to the growth of your business!

TAG: Beverage Filling Machine CSD Filling Lines Juice Filling Line

-

![Important Questions To Consider Before Purchasing Carbonated Filling Machine]() Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023

Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023 -

![Classification of beverage filling machines]() Classification of beverage filling machinesMar , 24 /2023

Classification of beverage filling machinesMar , 24 /2023 -

![Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling Machine]() Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023

Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023 -

![Fruit juice beverage filling production line]() Fruit juice beverage filling production lineApr , 21 /2023

Fruit juice beverage filling production lineApr , 21 /2023 -

![Application of Juice Beverage Filling Machine in the Industry]() Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023

Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023 -

![Introducing HZM Machinery Co., Ltd.: Your Trusted Supplier of CSD Filling Lines]() Introducing HZM Machinery Co., Ltd.: Your Trusted Supplier of CSD Filling LinesApr , 26 /2023

Introducing HZM Machinery Co., Ltd.: Your Trusted Supplier of CSD Filling LinesApr , 26 /2023 -

![Juice Filling Line equipment manufactory]() Juice Filling Line equipment manufactoryJun , 06 /2023

Juice Filling Line equipment manufactoryJun , 06 /2023 -

![Juice Beverage Filling Equipment: Detailed Introduction]() Juice Beverage Filling Equipment: Detailed IntroductionNov , 04 /2023

Juice Beverage Filling Equipment: Detailed IntroductionNov , 04 /2023

Home /

Home /