Key Points for Beer Filling in Beer Bottling Systems

When filling beer, it is essential to maintain strict sterility, minimize beer loss, prevent carbon dioxide (CO2) loss, and avoid contact between the beer and air to prevent oxidation. The filling valves must be clean and provide a good seal to prevent turbulence and beer surging. The structure of the filling machine mainly consists of the machine base, drive unit, beer buffer tank, lifting mechanism, and filling mechanism. Bottle filling machines typically employ a rotary structure and can accommodate up to 200 filling valves. Empty bottles are conveyed into the filling machine on a conveyor belt, separated at regular intervals by a bottle divider, and then rotated by an input star wheel onto elevatable trays. Finally, the beer is filled under the machine, and the trays are lowered to remove the filled bottles.

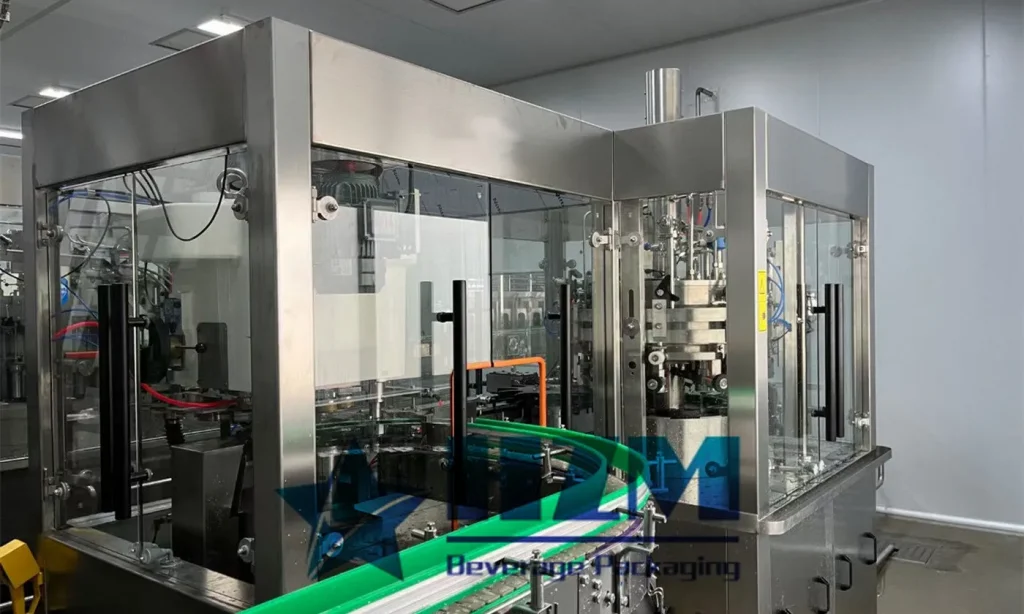

Füller,Grüne Behälter,Füllerkarussell

(1) Performance Requirements for Beer Filling Machines:

- The nominal production capacity of a filling machine is the number of beer bottles filled per hour. Standard series filling machines typically have capacities of 24,000, 36,000, 48,000, and 60,000 bottles per hour. Internationally, capacities can reach up to 150,000 bottles per hour, with 140–150 beer valves for a filling machine with a capacity of 60,000 bottles per hour.

- Beer filling liquid level accuracy must meet specific standards. In China, the liquid level difference should be ≤12mm, with an accuracy rate of 93% for 20,000–30,000 bottles per hour. Internationally, the liquid level difference is ±3mm, with an accuracy rate of 80%, or ±5mm with an accuracy rate of 98%.

- The beer loss rate during filling should be ≤0.8%.

- CO2 loss during filling should be ≤1.0g/L, with an oxygen increase of 0.02mg/L. The bottle neck air volume should be kept below 2ml/bottle, ideally between 0.5–1ml/bottle.

- The bottle breakage rate should be ≤0.7%.

(2) Key Process Requirements:

- Beer should be filled under isobaric conditions, and its temperature should be low, generally around -1°C to 2°C, to minimize the loss of CO2 and beer spillage.

- The sealing performance of the beer valves and the clarity of beer pipes should be excellent. The air pressure on the bottle carriers should be sufficient, maintained between 0.25–0.32MPa, and the distance from the beer pipe mouth of long-tube valves to the bottle bottom should be 1.5–3.0cm.

- After filling, beer bottles should be purged with beer or CO2 at a pressure of 0.2–0.4MPa to remove air from the bottle neck.

- The beer volume should be maintained at 640ml ± 10ml or 355ml ± 5ml. The liquid level height should be consistent, with 4%–5% headspace.

- During the filling process, unfilled bottles should not be manually topped up, and hands should not approach the bottle mouth.

Additionally, the following requirements should be met: CO2 mass fraction controlled between 0.45% and 0.55%, dissolved oxygen content less than 0.3mg/L, and compliance with other criteria outlined in GB4927 standards. Beer storage tanks should be pressurized with CO2 or nitrogen, with pressure controlled at 0.06–0.08MPa. Two-stage vacuum and CO2 counter-pressure filling should be used. Measures such as dripping water to remove foam from the bottle neck air should be employed. Attention should be given to environmental hygiene and aseptic operations. Filtered beer should be kept at a low temperature under a backpressure of 0.06–0.08MPa for 14–18 hours before filling. Filling should occur under constant temperature, pressure, and speed to minimize CO2 loss from the beer. Secondary beer resulting from filling should be treated through deoxygenation, sterilization, and CO2 enrichment before recycling.

(3) Filling Operation:

- Before filling, the filling machine should be cleaned and sterilized. If the machine has been idle for over 24 hours, it should be cleaned with a 2% alkaline solution at 60–65°C for 20–30 minutes, followed by rinsing with sterile sand-filtered water. The beer storage tank (or vat) should be pre-pressurized with CO2, and beer should be slowly and steadily transferred from the beer tank to the beer vat of the filling machine to maintain the beer level at 2/3 of the vat's height.

- During filling, the beer vat's liquid level, pressure, and filling speed should be kept stable.

- After filling, mechanical tapping, ultrasonic foam induction, or high-pressure jet devices can be used to inject a small amount of beer, sterile water, or CO2 into the bottle to remove air from the bottle neck, followed by capping.

- Troubleshooting and Resolution for Bottle Filling:

A. Excessive liquid level in bottles: Possible causes include defective sealing rubber rings in beer valves, leaky pressure relief valves, vacuum valves, or overly short or bent return air pipes.

B. Bottles not filled to capacity: Possible causes include incorrect adjustment of air valve opening, insufficient bottle carrier air pressure, damaged bottle doors, excessively small air valve or beer valve openings.

C. Surging during filling: Possible causes include high beer temperature, high CO2 content, unstable backpressure and beer pressure, excessively high bottle carrier air pressure, air valve leakage, air valve not closing, short depressurization time or worn cam lobes, and unclean bottles.

D. Failure to dispense beer during filling: Possible causes include malfunctioning isobaric springs, blocked return air pipes, and sticky beer valves.

TAG: Beer Filling Machine Carbonated Filling Machine Glass Bottle Filling Machine

-

![Carbonated Beverage Filling Machine Solution]() Carbonated Beverage Filling Machine SolutionApr , 22 /2023

Carbonated Beverage Filling Machine SolutionApr , 22 /2023 -

![Fully Understanding Automatic Beverage Filling Machines]() Fully Understanding Automatic Beverage Filling MachinesMay , 08 /2023

Fully Understanding Automatic Beverage Filling MachinesMay , 08 /2023 -

![Glass Bottle Packaging Equipment]() Glass Bottle Packaging EquipmentJun , 07 /2023

Glass Bottle Packaging EquipmentJun , 07 /2023 -

![28000 BPH SS316 Carbonated Soft Drink Filling Machine For Sale]() 28000 BPH SS316 Carbonated Soft Drink Filling Machine For SaleJun , 09 /2023

28000 BPH SS316 Carbonated Soft Drink Filling Machine For SaleJun , 09 /2023 -

![Coffee Tea Granule Glass Bottle Filling Machine]() Coffee Tea Granule Glass Bottle Filling MachineJun , 09 /2023

Coffee Tea Granule Glass Bottle Filling MachineJun , 09 /2023 -

![Full Automatic All In One 8000 Bph Glass Bottle Filling Machine]() Full Automatic All In One 8000 Bph Glass Bottle Filling MachineJun , 09 /2023

Full Automatic All In One 8000 Bph Glass Bottle Filling MachineJun , 09 /2023 -

![Soda Sparkling Water 8000 BPH Glass Bottle Filling Machine]() Soda Sparkling Water 8000 BPH Glass Bottle Filling MachineJun , 09 /2023

Soda Sparkling Water 8000 BPH Glass Bottle Filling MachineJun , 09 /2023 -

![Enhancing Production Efficiency and Quality-Beverage Filling Machines]() Enhancing Production Efficiency and Quality-Beverage Filling MachinesJun , 16 /2023

Enhancing Production Efficiency and Quality-Beverage Filling MachinesJun , 16 /2023 -

![Beer Bottling Machines for Sale by HZM Machinery]() Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023

Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023 -

![small scale beer bottling equipment]() small scale beer bottling equipmentSep , 20 /2023

small scale beer bottling equipmentSep , 20 /2023 -

![Beer Filling Machine Principle]() Beer Filling Machine PrincipleOct , 03 /2023

Beer Filling Machine PrincipleOct , 03 /2023 -

![Basic Principles of Beer Packaging]() Basic Principles of Beer PackagingOct , 05 /2023

Basic Principles of Beer PackagingOct , 05 /2023

Home /

Home /