How to Perform Maintenance on Edible Oil Filling Machine with Oil Leakage

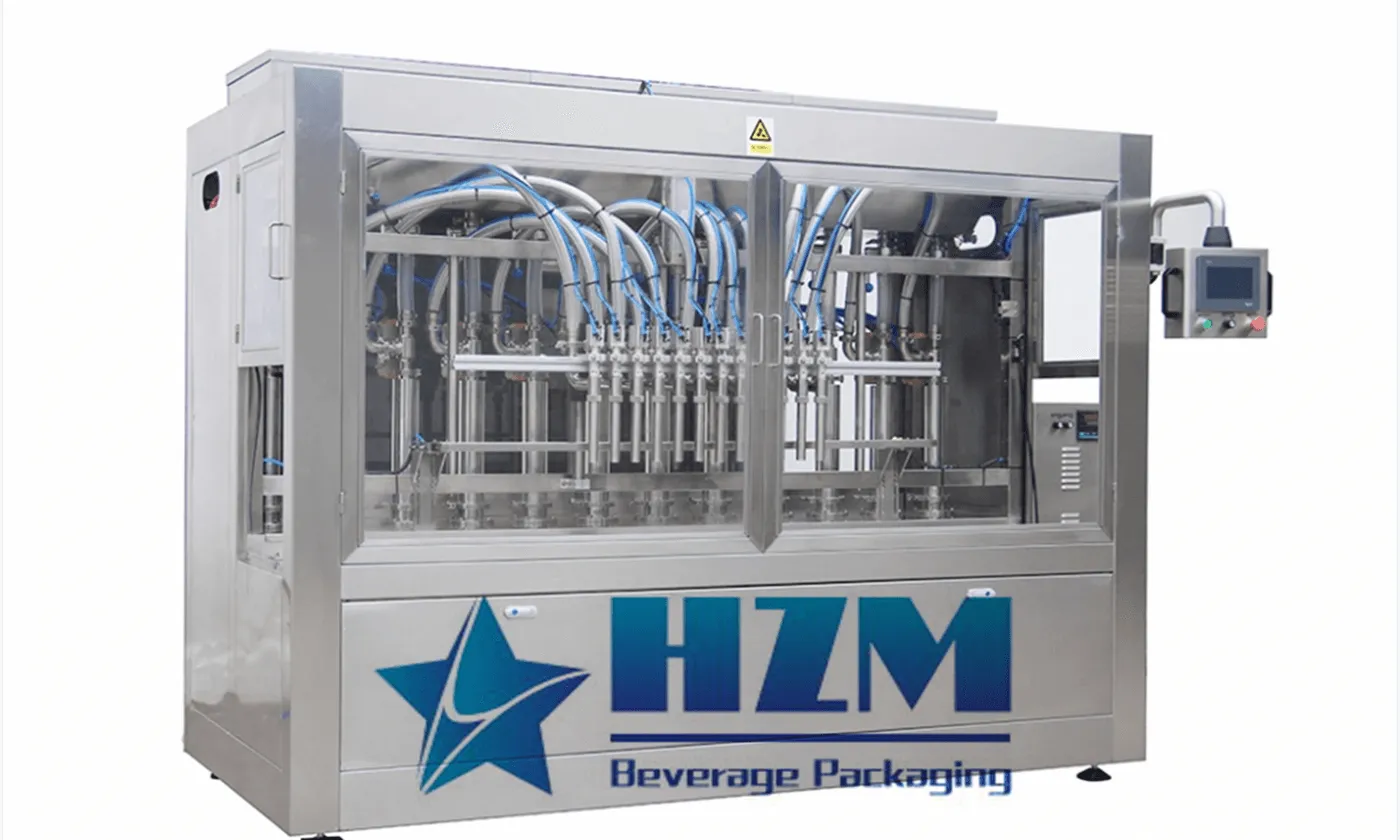

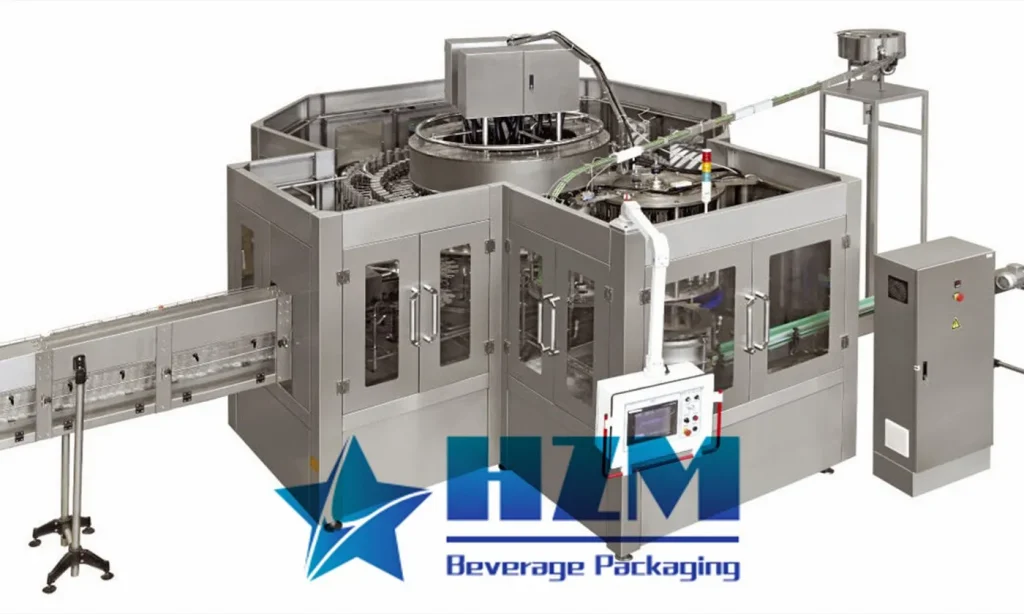

HZM Machinery, as your partner, offers the support of professional after-sales service engineers for the maintenance of edible oil filling machines.

When an edible oil filling machine experiences an oil leakage issue, it is crucial to conduct timely maintenance to ensure the proper functioning of the equipment while avoiding unnecessary production losses. Here are some basic maintenance steps for addressing oil leakage problems in an edible oil filling machine.

Step 1: Shutdown and Power Disconnection

First and foremost, when your edible oil filling machine experiences an oil leakage issue, it's essential to shut down the machine and disconnect the power supply to ensure safety during maintenance.

Step 2: Involvement of Professional After-Sales Service Engineers

During the maintenance process, you can rely on the expertise of HZM Machinery's professional after-sales service engineers. They possess extensive experience and knowledge, enabling them to quickly identify issues and provide solutions.

Step 3: Inspection of Oil Leakage Points

Professional after-sales service engineers will assist you in inspecting the equipment to determine the exact location of the oil leakage points. These points can be located in seals, valves, pipelines, or connection parts. Through visual inspection, they can pinpoint the exact location of the oil leakage.

Step 4: Cleaning of the Oil Leakage Area

The area with oil leakage will be thoroughly cleaned to ensure there are no residues or contaminants. This aids professional engineers in accurately detecting the oil leakage points.

Step 5: Inspection of Seals and Components

Professional after-sales service engineers will carefully inspect all seals, including rubber gaskets, washers, O-rings, and sealing rings, to ensure they are undamaged or not worn out. If necessary, they will replace damaged seals.

Step 6: Inspection of Valves, Pipelines, and Connections

Engineers will examine all valves, pipelines, and connection parts to ensure they are free of cracks, loosening, or damage. Repairs or replacements will be made as required.

Step 7: Examination of Oil Hoses

The oil hose system will undergo a thorough inspection to ensure there are no leaks or oil seepage areas. Damaged oil hoses will be repaired or replaced.

Step 8: Reassembly and Testing

After the maintenance process, professional after-sales service engineers will reassemble the equipment, ensuring that all components are correctly installed and fastened to prevent future oil leakage issues. They will assist in restarting the equipment and conducting tests and inspections to confirm that the oil leakage problem has been resolved.

Step 9: Preventive Maintenance Advice

To prevent future oil leakage problems, professional engineers typically provide advice on preventive maintenance. This includes the regular replacement of seals, checking valves and pipelines, and maintaining the equipment's cleanliness and lubrication.

HZM Machinery is a comprehensive manufacturer specializing in the development, manufacturing, and sales of edible oil filling machines. We offer top-quality equipment to the edible oil production industry. Additionally, we have a team of professional after-sales service engineers to ensure that your equipment receives timely and expert support.

TAG: Edible Oil Filling Machine Oil Filling Machine

-

![How to Choose the Best Fully Automatic Edible Oil Filling Machine]() How to Choose the Best Fully Automatic Edible Oil Filling MachineMay , 04 /2023

How to Choose the Best Fully Automatic Edible Oil Filling MachineMay , 04 /2023 -

![Filling Machine, Classification, Workflow, Instructions for Use, Procurement]() Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023

Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023 -

![How much does an edible oil filling machine cost per unit, and how to choose the right one?]() How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023

How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023 -

![Edible Oil Bottle Filling Machine: Manufacturers and Pricing]() Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023

Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023 -

![Edible Oil Filling Machine Manual]() Edible Oil Filling Machine ManualOct , 12 /2023

Edible Oil Filling Machine ManualOct , 12 /2023 -

![Operation Procedure and Precautions for Edible Oil Filling Machine]() Operation Procedure and Precautions for Edible Oil Filling MachineOct , 18 /2023

Operation Procedure and Precautions for Edible Oil Filling MachineOct , 18 /2023 -

![What is an edible oil filling machine?]() What is an edible oil filling machine?Oct , 22 /2023

What is an edible oil filling machine?Oct , 22 /2023 -

![What equipment does the edible oil filling production line include?]() What equipment does the edible oil filling production line include?Oct , 25 /2023

What equipment does the edible oil filling production line include?Oct , 25 /2023

Home /

Home /