How much does a bottling machine cost

When it comes to the manufacturing and packaging industry, bottling machines play a crucial role in ensuring efficient production and timely delivery of products. From beverages to pharmaceuticals, these machines are designed to fill, cap, and seal bottles with precision and consistency. However, one common question that arises is how much does a bottling machine cost? In this article, we will dive into the factors that determine the cost of a bottling machine, explore different types of machines available in the market, and discuss their benefits.

Factors Influencing the Cost

1. Machine Type:

The type of bottling machine significantly affects its cost. There are various types available, including rotary filling machines, overflow fillers, piston fillers, and gravity fillers. Each type has its own advantages and is suitable for specific applications. Generally, rotary filling machines are the most expensive due to their high-speed capabilities and versatility.

2. Production Capacity:

The capacity of a bottling machine is another essential factor that influences its cost. Machines with higher production rates and larger capacity command higher prices. It is crucial to estimate your production requirements accurately and choose a machine that can cater to your needs efficiently.

3. Automation Level:

The level of automation in a bottling machine can vary significantly. Fully automated machines, equipped with advanced features like bottle positioning, filling level sensors, and automatic capping, tend to be more expensive. However, they offer increased productivity, reduced human error, and enhanced efficiency in the long run.

Types of Bottling Machines

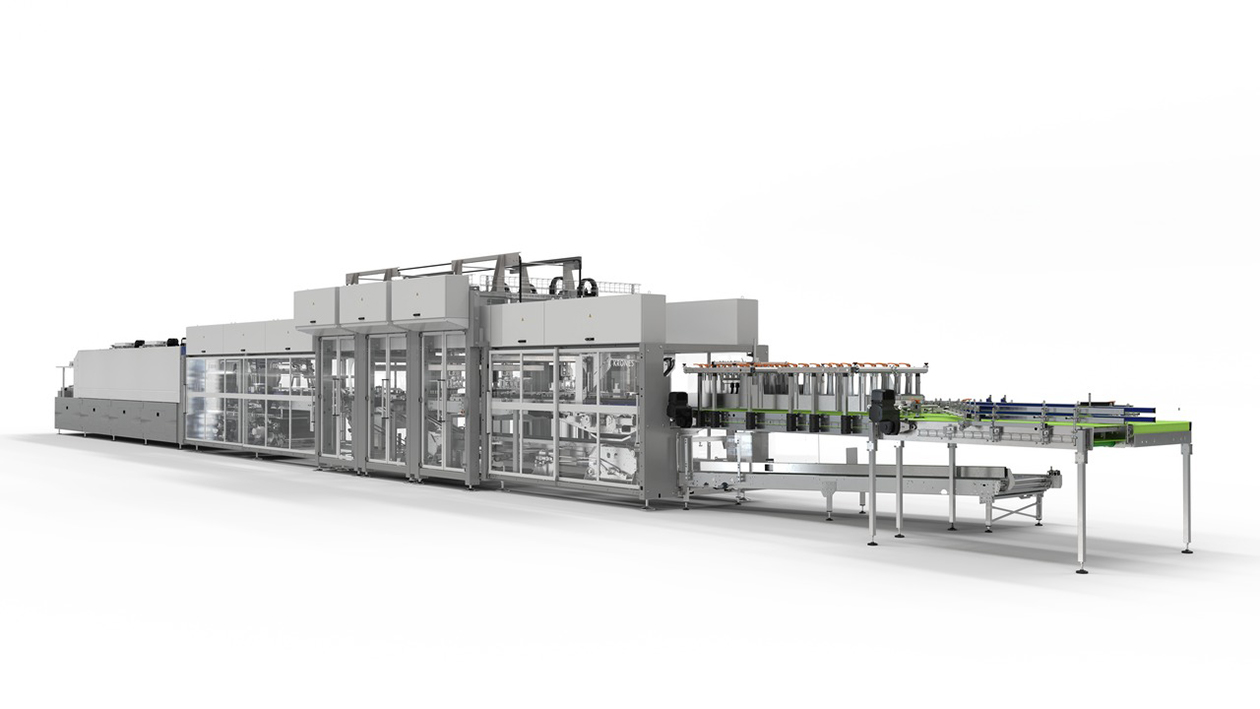

1. Rotary Filling Machines:

Rotary filling machines are widely used in industries that require high-speed filling. These machines consist of multiple stations, each dedicated to a specific task, such as bottle cleaning, filling, capping, and labeling. They offer fast and efficient production, making them suitable for large-scale manufacturing facilities.

2. Overflow Fillers:

Overflow fillers are ideal for filling containers with foaming or viscous liquids. These machines use a unique filling method where the liquid overflows into the container, ensuring consistent fill levels and minimizing the risk of spillage. They are commonly used in industries such as cosmetics, pharmaceuticals, and food processing.

3. Piston Fillers:

Piston fillers are suitable for filling a wide range of products, from liquids to creams and pastes. They operate by using a piston to draw the product from the reservoir and dispense it into the bottles. These machines offer excellent accuracy and control over fill volumes, making them popular in the pharmaceutical and chemical industries.

Benefits of Bottling Machines

1. Increased Efficiency:

Bottling machines automate the entire packaging process, leading to improved efficiency and productivity. They can handle large volumes of bottles in a shorter time, reducing manual labor and operational costs.

2. Consistency in Fill Levels:

One of the critical aspects of packaging is ensuring consistent fill levels. Bottling machines offer precise control over fill volumes, reducing wastage and ensuring uniformity in product packaging.

3. Reduced Packaging Errors:

Manual packaging is prone to errors and inconsistencies. Bottling machines eliminate human error by automating the process, resulting in accurately packaged products and minimizing the risk of customer complaints or recalls.

4. Cost Savings:

While bottling machines require an upfront investment, they can lead to substantial cost savings in the long run. With increased efficiency and reduced wastage, businesses can optimize their production and reduce operational expenses.

Investing in a bottling machine can significantly enhance your production capabilities and streamline the packaging process. The cost of a bottling machine depends on various factors, including the machine type, production capacity, and automation level. It is essential to assess your specific requirements and choose a machine that offers the best value for money. With the benefits of increased efficiency, consistency, reduced errors, and long-term cost savings, bottling machines are a worthy investment for businesses in the manufacturing and packaging industry.

At Huazhen Machinery (HZM) Co., Ltd. we have been committed to providing our customers with high quality liquid beverage packaging machinery solutions. Our company has become a professional supplier in the field of liquid beverage packaging machinery with its excellent R&D, manufacturing and sales capabilities. As a company with strict quality inspection standards, we are guaranteed by international quality management system certifications such as CE and ISO 9001:2015 to ensure that every detail of our products is carefully inspected to meet customers’ expectations and requirements. Our team is always striving for excellence to ensure the performance, durability and stability of each bottling machine. At Huazhen Machinery, we believe that no matter what the cost of a bottling machine is, we are always striving to exceed your expectations. Thank you for your attention and support, and we look forward to continuing to work with you to create a brighter future. If you have any needs about bottling machine or other packaging machinery, why don’t you contact us, we will be happy to provide you with the best solution.

TAG: Bottling Machine Packaging machine Water Bottling Machine

-

![Five Tips for Choosing the Right Packaging Machine for Your Business]() Five Tips for Choosing the Right Packaging Machine for Your BusinessApr , 24 /2023

Five Tips for Choosing the Right Packaging Machine for Your BusinessApr , 24 /2023 -

![Mineral Water Bottling Production Line Process]() Mineral Water Bottling Production Line ProcessJul , 06 /2023

Mineral Water Bottling Production Line ProcessJul , 06 /2023 -

![Overview of Packaging Machine Types and Classification Methods]() Overview of Packaging Machine Types and Classification MethodsAug , 11 /2023

Overview of Packaging Machine Types and Classification MethodsAug , 11 /2023 -

![Design and Electrical Control of Fully Automatic Carton Packaging Machine]() Design and Electrical Control of Fully Automatic Carton Packaging MachineAug , 15 /2023

Design and Electrical Control of Fully Automatic Carton Packaging MachineAug , 15 /2023 -

![What is a Beverage Packaging Machine?]() What is a Beverage Packaging Machine?Aug , 25 /2023

What is a Beverage Packaging Machine?Aug , 25 /2023 -

![Bottled water production process PDF]() Bottled water production process PDFSep , 18 /2023

Bottled water production process PDFSep , 18 /2023 -

![Mineral Water Machine Price in Pakistan: A Comprehensive Guide]() Mineral Water Machine Price in Pakistan: A Comprehensive GuideSep , 30 /2023

Mineral Water Machine Price in Pakistan: A Comprehensive GuideSep , 30 /2023 -

![Mineral Water Production Cost]() Mineral Water Production CostOct , 01 /2023

Mineral Water Production CostOct , 01 /2023

Home /

Home /