how does a blow molding machine work

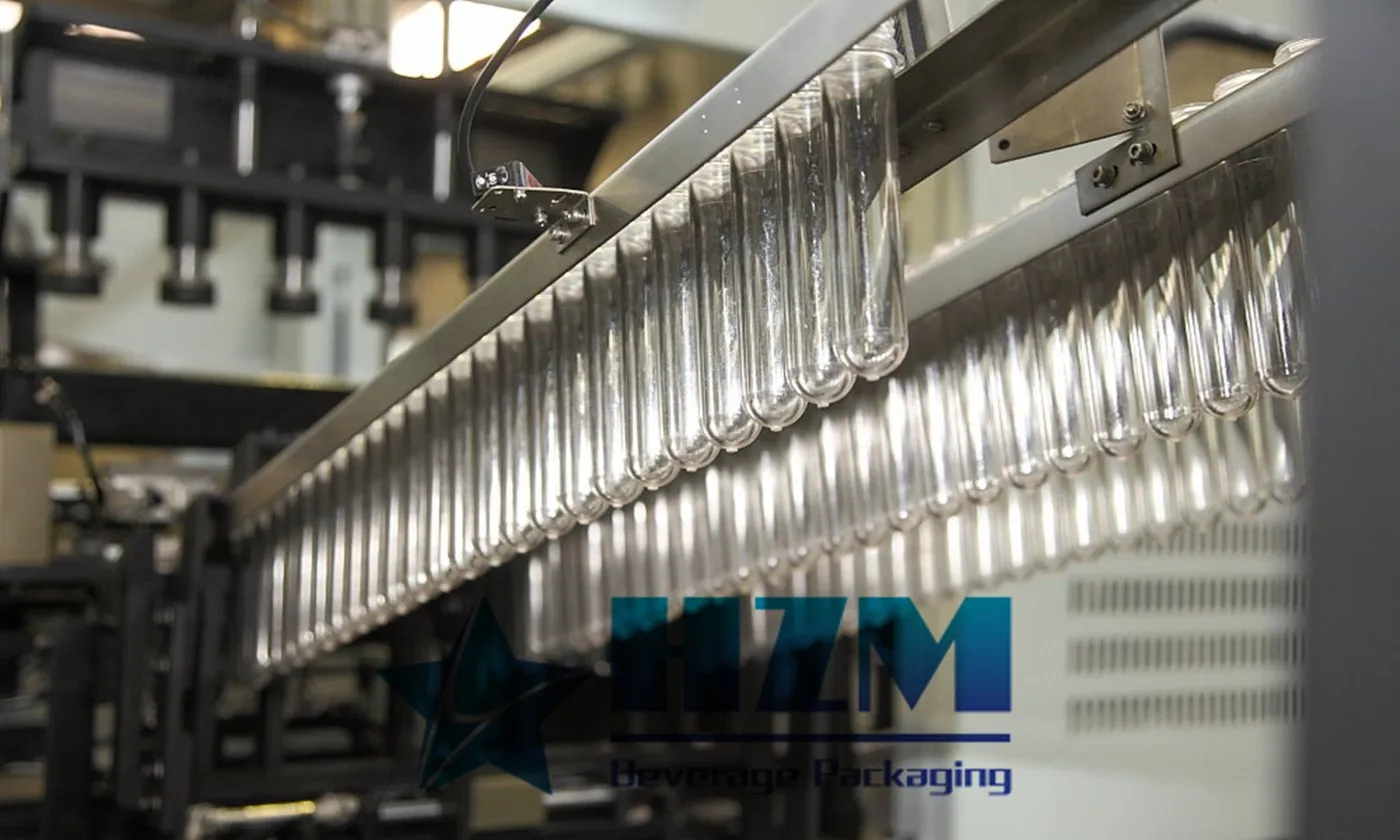

Blow molding machines are essential equipment in the manufacturing industry for producing various plastic products, including bottles, containers, and other hollow objects. Understanding how these machines work is crucial for those interested in the manufacturing process. In this article, we will explore the working principle of a blow molding machine, with insights from HZM Blow Molding Machine Manufacturer, a leading provider of high-quality blow molding machines.

Working Principle: The blow molding process typically involves three main steps: extrusion, molding, and cooling. Let's delve into each step:

- Extrusion: The process starts with the extrusion phase. Plastic material, usually in the form of pellets or granules, is fed into the extruder of the blow molding machine. The material is then melted and formed into a molten tube or parison through the use of heat and pressure. HZM Blow Molding Machine Manufacturer utilizes advanced extrusion technology to ensure precise control of temperature, speed, and material distribution.

- Molding: Once the parison is formed, it moves to the molding station. Here, the parison is clamped between two halves of a mold. The mold is designed to match the desired shape of the final product. HZM Blow Molding Machine Manufacturer focuses on high-quality molds that ensure accuracy and consistency during the molding process. The mold is then closed, creating a sealed cavity where the parison takes the shape of the mold.

- Cooling: After the parison is shaped, the cooling process begins. The mold is cooled using either air or water to solidify the plastic and allow it to retain its shape. HZM Blow Molding Machine Manufacturer incorporates efficient cooling systems to expedite the cooling process, ensuring shorter cycle times and higher production efficiency. Once the plastic has cooled and solidified, the mold opens, and the finished product is ejected from the machine.

HZM Blow Molding Machine Manufacturer: As a leading blow molding machine manufacturer, HZM emphasizes precision, efficiency, and reliability in their machines. They leverage advanced technology and expertise to design and manufacture blow molding machines that deliver superior performance and consistent product quality. HZM's machines incorporate features such as precise control systems, high-speed operation, and easy-to-use interfaces, ensuring optimal results and operator convenience.

Conclusion: Blow molding machines, including those manufactured by HZM, operate through a well-defined process involving extrusion, molding, and cooling. By understanding the working principle, manufacturers can optimize production efficiency and produce high-quality plastic products. HZM Blow Molding Machine Manufacturer's commitment to technological advancements and quality ensures that their machines deliver reliable performance and meet the diverse needs of the manufacturing industry.

TAG: Blow Molding Machine

-

![Successful Delivery of New Blow Molding Machine to Indonesian Customer]() Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023

Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023 -

![The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and Precision]() The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023

The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023 -

![Automatic Rotary Blow Molding Machine: Features, Applications, and Maintenance]() Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023

Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023 -

![Maintenance and Care of 5 Gallon Bottle Blow Molding Machine]() Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023

Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023

Home /

Home /