How Do Label Machines Work?

Labels are vital aspects of every business because these help in different business aspects ranging from packaging to presentation, identification, and traceability. These serve as a communicating way of communication from manufacturers to the customers and the world. Labels help in promoting the product brand and indicate important information about the product that consumers need to know.

In addition, labels also facilitate tracking and tracing products within the supply chain. So, here we will look at the key working principle of labeling machines and their types for further knowledge.

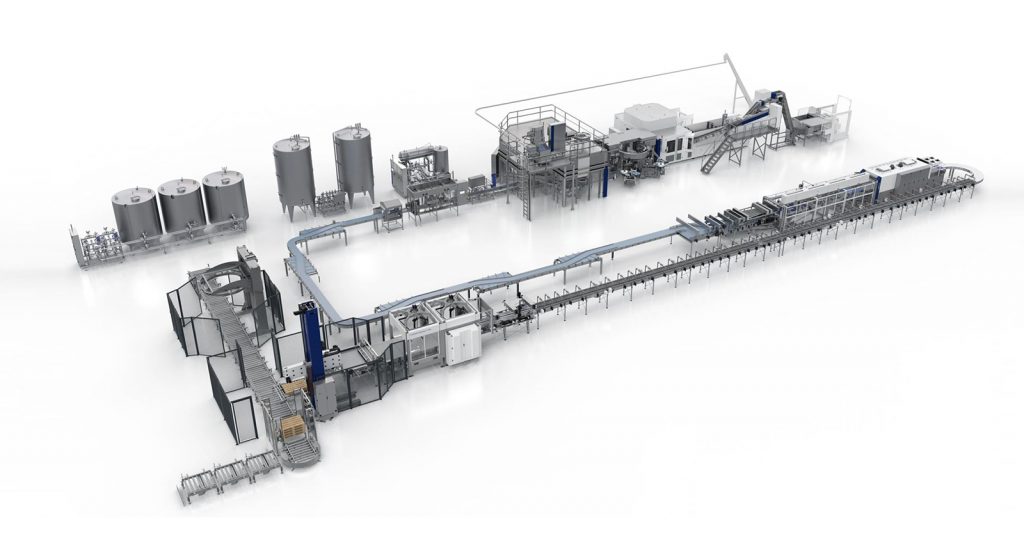

Different types of labeling machines

Labeling requirements of businesses are usually different because of the different label materials and shapes of required objects. It would be better to understand the most appropriate labeling machine for your business to meet all your labeling needs in different circumstances. Here we have enlisted different varieties and types of labeling machines to give you an idea.

So, here we go:

Manual labeling machine

Semi-automatic labeling machine

Automatic labeling machine

The labeling, as mentioned above, machine types are based on the automation degree. However, when it’s to labeling function, the categories are usually divided into side labeling machines, flat labeling machines, wrap-around labeling machines, and corner labeling machines.

How does a labeling machine work?

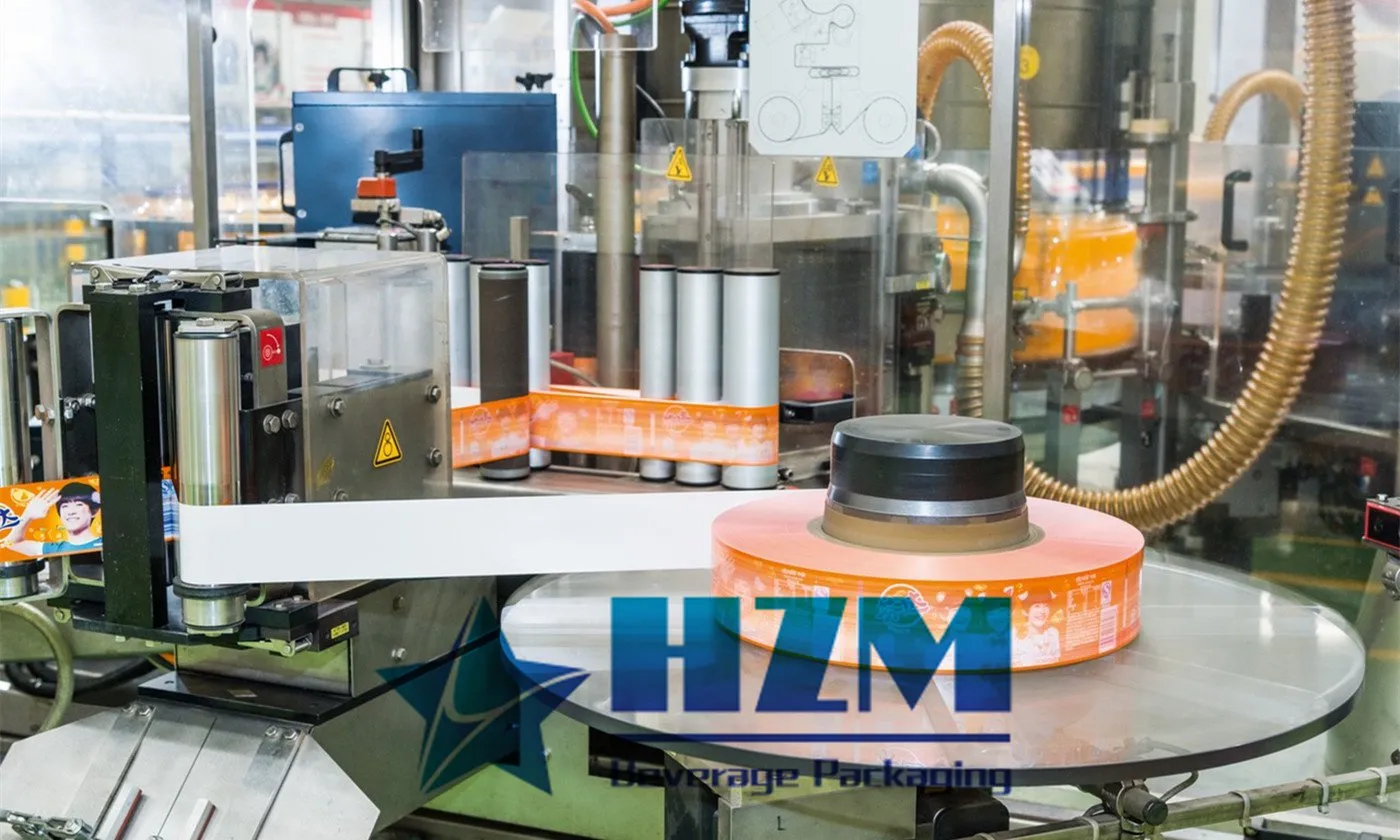

The work process of the labeling machine starts by feeding the bottle to the labeling machine on the conveyor at a constant speed. The mechanical fixture can separate the bottle at a fixed distance and then push it toward the conveyor.

The typical mechanical system of a labeling machine includes a labeling wheel, a dry wheel, and a reel. The label belt is dragged by the drive wheel intermittently. The label wheel then presses against the bottle. The reel uses an open-loop displacement control to maintain the label strip tension.

Labels are connected closely on the strip; therefore, they must be stopped constantly. The practice is necessary to attach the label tape to the item with the labeling wheel moving at a constant speed. When the conveyor belt reaches a specific position, the speed will be accelerated by the label drive wheel to match the belt speed.

Once the label is attached, the speed will be deaccelerated to a stop.

At times the label may have a slight slip. Due to this, each label comes up with a mark to ensure its correct placement that the sensor will read. In the label’s deacceleration phase, the drive wheel of the labeling machine will also readjust its position. The position readjustment will ultimately help in correcting errors on the label.

Contact HZM Beverage Packaging to get your labeling machine.

HZM Beverage Packaging provides a variety of labeling machines. These range from automatic labeling machines to automatic sleeve labeling machines. They use premium quality raw materials in manufacturing these machines. So, consumers can benefit from their labeling machines for future generations. In addition, a longer after-sale guarantee with online and offline support can add more assurance and peace to your purchase.

So, if you want to get comprehensive technical support, after-sale services, and high-quality labeling machines, HZM Beverage Packaging can be your go-to destination.

TAG: Labeling Machine labeling machines

-

![Automatic Drinking Water Filling Production Line Equipment]() Automatic Drinking Water Filling Production Line EquipmentJul , 10 /2023

Automatic Drinking Water Filling Production Line EquipmentJul , 10 /2023 -

![How to create a complete Water Filling Line?]() How to create a complete Water Filling Line?Jul , 10 /2023

How to create a complete Water Filling Line?Jul , 10 /2023 -

![HZM Machinery: Providing the Perfect Solution for Beverage Production Line Equipment]() HZM Machinery: Providing the Perfect Solution for Beverage Production Line EquipmentAug , 18 /2023

HZM Machinery: Providing the Perfect Solution for Beverage Production Line EquipmentAug , 18 /2023 -

![Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling Machine]() Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling MachineAug , 22 /2023

Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling MachineAug , 22 /2023 -

![Automatic 150BPM Sleeve Shrink Labeling Machine]() Automatic 150BPM Sleeve Shrink Labeling MachineNov , 03 /2023

Automatic 150BPM Sleeve Shrink Labeling MachineNov , 03 /2023 -

![Essential Maintenance Tips for Labeling Machines]() Essential Maintenance Tips for Labeling MachinesFeb , 29 /2024

Essential Maintenance Tips for Labeling MachinesFeb , 29 /2024 -

![What Machines Are Used to Apply Plastic Labels on Beverage Bottles?]() What Machines Are Used to Apply Plastic Labels on Beverage Bottles?Jun , 14 /2024

What Machines Are Used to Apply Plastic Labels on Beverage Bottles?Jun , 14 /2024

Home /

Home /