Here are five things to consider for maintaining a fully automated mineral water production line

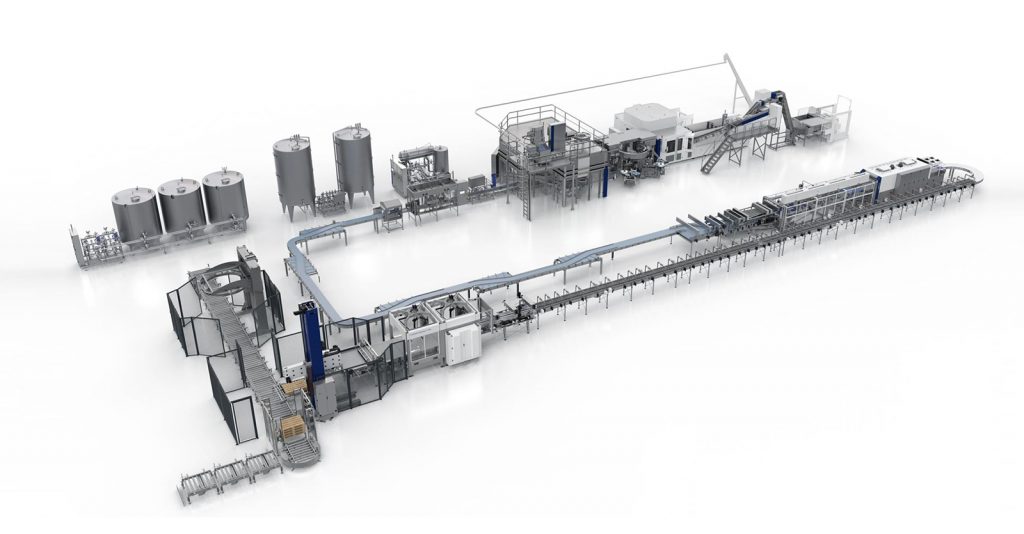

The fully automated mineral water production line is a device used for producing bottled mineral water, which can automatically complete a series of production processes such as filling, labeling, and sealing of mineral water. Its principle is to remove impurities and heavy metals from the water through complex physical and chemical reactions after preliminary treatment, while supplementing the minerals and trace elements needed by the human body, making the water clear, pure, and suitable for drinking

The main function of the fully automated mineral water production line is to produce high-quality bottled mineral water to meet people's demand for high-quality healthy drinks. It has high production efficiency, low production cost, easy operation, stable and reliable quality, and is deeply loved by consumers. However, the importance of daily maintenance standards for the fully automated mineral water production line is self-evident. Daily maintenance standards include the following aspects

- Regular cleaning of the filling pipes and containers of the fully automatic mineral water production line to ensure stable water quality and equipment hygiene.

- Regular inspection of the operation status of the production line equipment and the degree of wear of its components, and timely repair or replacement of any problematic parts.

- Regular replacement of the filters and cleaning of the water pumps on the production line to ensure the filtration effect and the cleanliness of the water source.

- Regular water quality testing to ensure that the quality of the produced mineral water meets national standards.

- Establishing a comprehensive material storage system, regularly updating procurement channels, and ensuring the qualification of the water source.

In daily maintenance, maintenance personnel should strictly follow the operating procedures to prevent non-professionals from opening the equipment for maintenance, and avoid equipment malfunctions or safety accidents. At the same time, attention should be paid to maintenance records, timely handling of equipment failures, and prevention of the impact on production schedules and product quality.

TAG: Water Filling Line Water treatment system

-

![12000BPH Pure Water Filling Line Debugging Successfully Completed]() 12000BPH Pure Water Filling Line Debugging Successfully CompletedMar , 24 /2023

12000BPH Pure Water Filling Line Debugging Successfully CompletedMar , 24 /2023 -

![Drinking Water Treatment System Manufacturer and Solutions]() Drinking Water Treatment System Manufacturer and SolutionsMay , 05 /2023

Drinking Water Treatment System Manufacturer and SolutionsMay , 05 /2023 -

![HZM Water Filling Line: Your Reliable Supplier for Complete Equipment Solutions]() HZM Water Filling Line: Your Reliable Supplier for Complete Equipment SolutionsJun , 06 /2023

HZM Water Filling Line: Your Reliable Supplier for Complete Equipment SolutionsJun , 06 /2023 -

![HZM Mineral Water Production Line Equipment Manufacturer]() HZM Mineral Water Production Line Equipment ManufacturerJun , 06 /2023

HZM Mineral Water Production Line Equipment ManufacturerJun , 06 /2023 -

![Mineral Water Production Line Equipment: Prices and Manufacturers]() Mineral Water Production Line Equipment: Prices and ManufacturersJun , 30 /2023

Mineral Water Production Line Equipment: Prices and ManufacturersJun , 30 /2023 -

![Water Filling Production Line: Efficient, Safe, and Stable Industry Solution]() Water Filling Production Line: Efficient, Safe, and Stable Industry SolutionJul , 04 /2023

Water Filling Production Line: Efficient, Safe, and Stable Industry SolutionJul , 04 /2023 -

![Automatic Drinking Water Filling Production Line Equipment]() Automatic Drinking Water Filling Production Line EquipmentJul , 10 /2023

Automatic Drinking Water Filling Production Line EquipmentJul , 10 /2023 -

![Bottled water production process PDF]() Bottled water production process PDFSep , 18 /2023

Bottled water production process PDFSep , 18 /2023

Home /

Home /