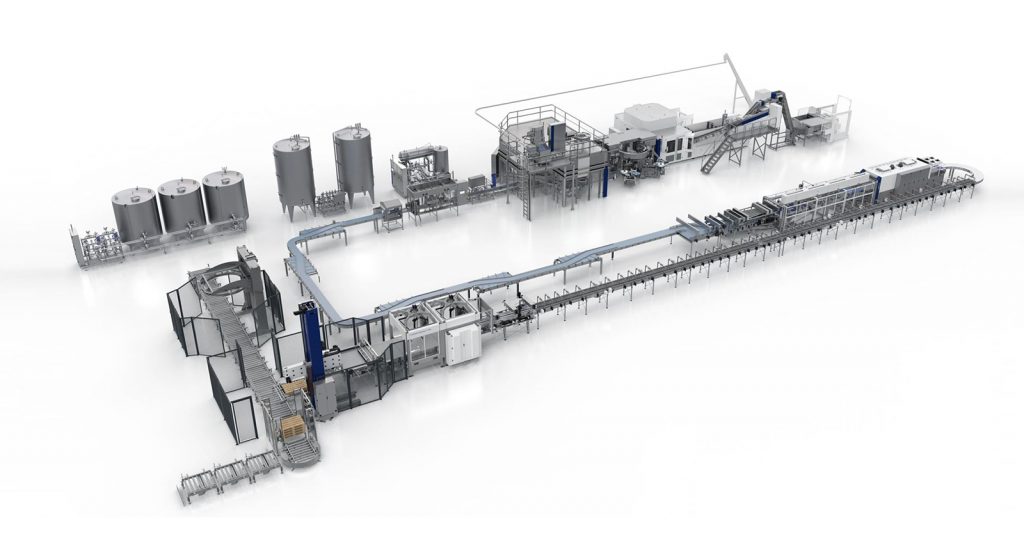

Fruit juice beverage filling production line

Juice and beverage filling production lines are used to produce and package juice and beverage products in PET plastic bottles, glass bottles, Tetra Pak packaging, and other forms. The filling capacity of the production line is typically 330ml, 500ml, 1L, 1.5L, and it can produce a variety of juice beverages such as mango juice, kiwi juice, peach juice, and more.

In terms of the complexity of the beverage production process, beverages made from fresh fruits are more complex to produce than those made from concentrated fruit purees because different fruits require different methods of juicing. Additionally, the process of producing clear juices requires more complex enzymatic clarification and filtration processes. Therefore, to purchase a complete beverage filling production line, it is necessary to determine the type of fruit, whether to make clear or cloudy juice, the percentage of fruit juice, sterilization methods, packaging types, labeling methods, and packaging materials, among other factors.

A juice and beverage filling production line consists of three main parts:

1、Water treatment system: Raw water can come from various sources such as wells, tap water, and rivers. The water treatment system can produce the required water quality based on the raw water quality report.

2、Juice and sugar preparation and mixing system: This system is typically used for concentrated juice and fruit powder. It includes a sugar melting pot, syrup filtration, mixing, homogenization, vacuum deaerator, and ultra-high-temperature sterilization machine.

3、Juice filling and packaging system: This system is mainly used for sterilizing the mouth and inner surface of the PET bottle and cap. The spraying system is suitable for cooling and heating various bottled or canned hot beverages or carbonated drinks.

What can we do for your juice and beverage production?

We can provide you with a complete set of juice and beverage filling production line equipment and process design diagrams, and the raw materials can be fresh fruit or concentrated fruit juice, allowing you to adjust the juice production plan flexibly.

Why choose our juice and beverage filling production line?

Our production line can be tailored to meet the individual needs of our customers. We offer various functional supports, including automatic control of the supply and capping systems, automatic detection of filling temperature, high-temperature material alarm, low-temperature shutdown and automatic reflux, no bottle no capping, waiting for bottles, and stopping the machine for missing caps. These functions not only improve production efficiency but also ensure product quality and production safety.

TAG: Juice Filling Line Juice Filling Machine

-

![A detailed introduction of the production line process for juice beverages]() A detailed introduction of the production line process for juice beveragesApr , 28 /2023

A detailed introduction of the production line process for juice beveragesApr , 28 /2023 -

![Juice Filling Line equipment manufactory]() Juice Filling Line equipment manufactoryJun , 06 /2023

Juice Filling Line equipment manufactoryJun , 06 /2023 -

![PET Plastic 1500ml Fruit Juice Filling And Packaging Machine]() PET Plastic 1500ml Fruit Juice Filling And Packaging MachineJun , 09 /2023

PET Plastic 1500ml Fruit Juice Filling And Packaging MachineJun , 09 /2023 -

![Self Cleaning Stainless Steel 9000kg Juice Filling Machine]() Self Cleaning Stainless Steel 9000kg Juice Filling MachineJun , 09 /2023

Self Cleaning Stainless Steel 9000kg Juice Filling MachineJun , 09 /2023 -

![Large-Scale Beverage Filling Line: Enhancing Efficiency and Innovation in Beverage]() Large-Scale Beverage Filling Line: Enhancing Efficiency and Innovation in BeverageJul , 24 /2023

Large-Scale Beverage Filling Line: Enhancing Efficiency and Innovation in BeverageJul , 24 /2023 -

![Juice Beverage Filling Equipment: Detailed Introduction]() Juice Beverage Filling Equipment: Detailed IntroductionNov , 04 /2023

Juice Beverage Filling Equipment: Detailed IntroductionNov , 04 /2023

Home /

Home /