Forms and Methods of Beer Packaging

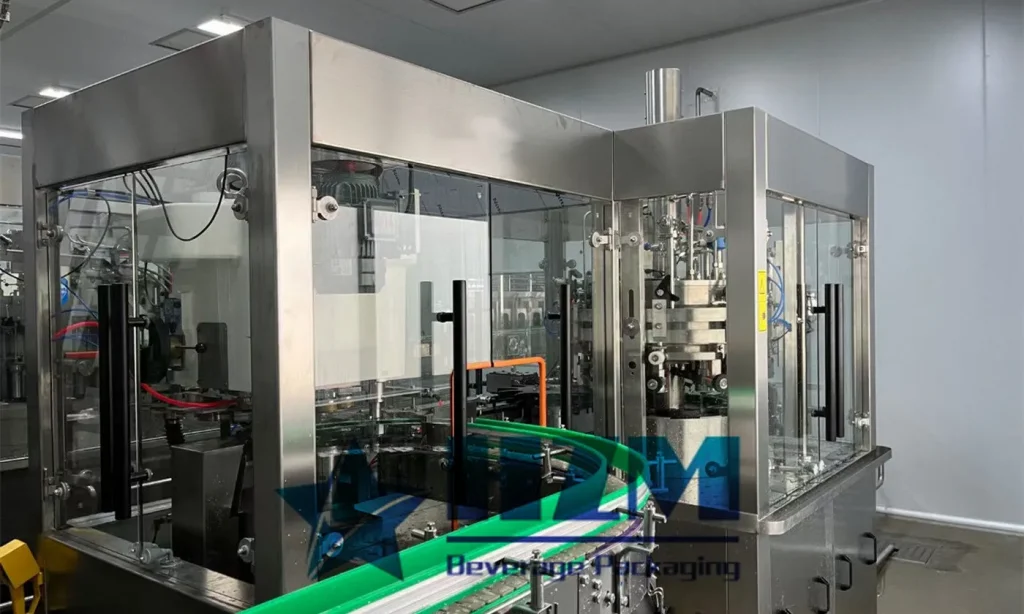

Beer packaging comes in various forms, including bottling (glass and polyester plastic), canning, and kegging. Among these, bottled beer, particularly mature beer in glass bottles, dominates the market share in China. In recent years, the production of bottled draft beer has been steadily increasing, and the sales outlook for kegged beer during peak seasons remains optimistic.

Different methods are employed for beer packaging, each with its unique advantages. The most common methods include pressurized filling, vacuum-assisted CO2 filling, double vacuum filling, CO2 counter-pressure filling, hot filling, and aseptic filling.

Pressurized Filling

Pressurized filling involves transferring beer into containers under a positive pressure, which helps minimize oxygen exposure. However, it is essential to control the pressure precisely to prevent over-foaming or under-filling.

Vacuum-Assisted CO2 Filling

This method combines a vacuum stage to remove air and a CO2 injection stage to fill the container with carbon dioxide. It effectively reduces the oxygen content in the beer, contributing to better product quality.

Double Vacuum Filling

Double vacuum filling is a more advanced technique that includes two vacuum stages. This approach further reduces the oxygen levels in the packaging process, enhancing beer freshness and stability.

CO2 Counter-Pressure Filling

CO2 counter-pressure filling maintains a balanced pressure inside the container to prevent foaming and oxidation. It ensures a consistent and high-quality beer product.

Hot Filling

Hot filling is suitable for certain beer types and involves filling containers with beer at an elevated temperature. This process can help extend the shelf life of the beer by sterilizing the container and preventing microbial contamination.

Aseptic Filling

Aseptic filling has gained prominence, particularly with the rise of draft beer. This method focuses on maintaining a sterile environment during the filling process, minimizing the risk of contamination and preserving the beer's freshness.

The choice of packaging method depends on various factors, including the type of beer, production volume, and market demand. While pressurized filling remains a common choice, the demand for draft beer and the emphasis on quality have driven advancements in vacuum-assisted, double vacuum, and aseptic filling techniques. Ultimately, the selection of the right packaging method plays a crucial role in delivering high-quality beer to consumers, ensuring a satisfying and consistent taste experience.

TAG: Beer Filling Machine Glass Bottle Filling Machine

-

![Glass Bottle Packaging Equipment]() Glass Bottle Packaging EquipmentJun , 07 /2023

Glass Bottle Packaging EquipmentJun , 07 /2023 -

![Coffee Tea Granule Glass Bottle Filling Machine]() Coffee Tea Granule Glass Bottle Filling MachineJun , 09 /2023

Coffee Tea Granule Glass Bottle Filling MachineJun , 09 /2023 -

![Full Automatic All In One 8000 Bph Glass Bottle Filling Machine]() Full Automatic All In One 8000 Bph Glass Bottle Filling MachineJun , 09 /2023

Full Automatic All In One 8000 Bph Glass Bottle Filling MachineJun , 09 /2023 -

![Magnetic Pump 500ml SS304 Glass Bottle Soda Filling Machine]() Magnetic Pump 500ml SS304 Glass Bottle Soda Filling MachineJun , 09 /2023

Magnetic Pump 500ml SS304 Glass Bottle Soda Filling MachineJun , 09 /2023 -

![Beer Bottling Machines for Sale by HZM Machinery]() Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023

Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023 -

![small scale beer bottling equipment]() small scale beer bottling equipmentSep , 20 /2023

small scale beer bottling equipmentSep , 20 /2023 -

![Beer Filling Machine Principle]() Beer Filling Machine PrincipleOct , 03 /2023

Beer Filling Machine PrincipleOct , 03 /2023 -

![Basic Principles of Beer Packaging]() Basic Principles of Beer PackagingOct , 05 /2023

Basic Principles of Beer PackagingOct , 05 /2023

Home /

Home /