Filling Machine, Classification, Workflow, Instructions for Use, Procurement

The filling machine is a small category of products in the packaging machine. From the perspective of material packaging, it can be divided into liquid filling machines, paste filling machines, powder filling machines, and granule filling machines. From the level of production automation, it can be classified as semi-automatic filling machines and fully automatic filling production lines.

Manufacturing Technology

- Photoelectric self-control sauce filling machine

- Countable quantitative pure water filling machine

- Wireless remote control mobile fully automatic filling machine

- A type of filling machine

- Filling machine star wheel clamp

- Fresh beer filling machine

- Residual liquid recovery device for vacuum cap-down filling machine

- Vacuum cap-down filling machine sealing and vacuum lifting device

- Vacuum cap-down filling machine

- Cap flushing device for vacuum cap-down filling machine

- Adjustable flow control valve for liquid filling machine

- Cup distribution mechanism for beverage filling machine

- Cup dropping device for paper cup filling machine

- Pre-formed cup lid film conveyor for filling machine

- A new type of automatic filling machine metering device

machine classification

Filling machines can be classified according to the filling principle as follows: atmospheric pressure filling machine, pressure filling machine, liquid filling machine, oil filling machine, paste filling machine, sauce filling machine, granule slurry filling machine, powder filling machine, large barrel water filling machine, and vacuum filling machine.

Atmospheric pressure filling machine:

This type of filling machine operates under atmospheric pressure, relying on the liquid's own weight for filling. It can be further divided into timed filling and volumetric filling. It is suitable for filling low-viscosity liquids without gas, such as milk, liquor, mineral water, etc.

Pressure filling machine:

The pressure filling machine operates under pressure higher than atmospheric pressure. It can be divided into two types: one where the pressure in the storage tank is equal to the pressure in the bottle, and the liquid flows into the bottle by its own weight, known as equal pressure filling; the other where the pressure in the storage tank is higher than the pressure in the bottle, and the liquid enters the bottle by pressure difference. This method is commonly used in high-speed production lines. Pressure filling machines are suitable for filling liquids containing gas, such as beer, soda, champagne, etc.

Vacuum filling machine:

The vacuum filling machine operates when the pressure inside the bottle is lower than atmospheric pressure. This type of filling machine has a simple structure, high efficiency, and a wide range of viscosity adaptability. It can be used for filling materials such as oils, syrups, fruit wines, etc.

Oil filling machine:

Oil filling machines are designed specifically for filling various types of oils, such as edible oil, lubricating oil, peanut oil, soybean oil, etc. These machines can be configured for both manual and automated operations, such as an edible oil filling machine. They can be classified based on measurement methods, such as flow meter type, piston type, and weighing type. They can also be categorized based on equipment styles, such as linear type and rotary type. Most oil filling machine manufacturers in China are located in Shandong, Guangdong, and Jiangsu provinces.

Plunger filling machine:

This type of filling machine is widely used in pharmaceutical, food, daily chemical, oil, pesticide, and other industries. It can fill various liquids and paste-like products, such as disinfectants, hand sanitizers, toothpaste, ointments, cosmetics, etc.

Liquid filling machine:

It features a new horizontal design that is lightweight and convenient. It automatically draws the material and can be equipped with a feeding hopper for thicker pastes. It can switch between manual and automatic modes. In the automatic mode, the machine performs continuous filling at the set speed. In the manual mode, the operator can use a foot pedal to initiate the filling process, and if the pedal is continuously pressed, it switches to automatic continuous filling. It also has an anti-drip filling system using cylinder movements to drive the filling head.

Additional accessories:

a. Needle filling head: Suitable for filling products in small-caliber bottles and soft tube packaging. The needle diameter and length can be customized according to the specific size of the container.

b. Rotary/ball valve control system: Suitable for materials with different viscosities and containing particles, it can solve various pressure issues caused by high level or high-pressure feeding.

c. Hopper: Recommended for filling high-viscosity products to achieve better filling results.

Paste filling machine:

Ideal for filling various viscosity products from aqueous solutions to creams. It is suitable for industries such as daily chemical, pharmaceutical, food, and pesticide.

Sauce filling machine:

Suitable for filling viscous sauces with large particles and high concentration, such as chili sauce, bean paste, peanut butter, sesame paste, jam, butter hot pot base, red oil hot pot base, etc.

According to the operation process, filling machines can be classified as fully automatic filling machines and semi-automatic filling machines.

Weighing filling machine:

Suitable for low-viscosity liquid materials, such as paints, coatings, resins, and various chemical raw materials.

Granule slurry filling machine:

It is an ideal filling equipment for granular and slurry-like viscous fluids, suitable for industries such as pharmaceutical, daily chemical, food, pesticides, and special sectors. This machine is a semi-automatic piston filling machine designed for filling granular and slurry-like fluid materials.

The machine has a small and compact design with a vertical structure, saving space. It is easy to operate, and the pneumatic components are from German brand FESTO and Taiwanese brand AirTac. The parts in contact with the material are made of 316L stainless steel, meeting GMP requirements. The filling valve is controlled by a pneumatic valve, providing higher filling accuracy. The filling volume and speed can be adjusted as needed. The filling head adopts anti-drawing and lifting filling device.

Powder filling machine:

This machine is suitable for quantitative filling of powder and small granular materials in industries such as chemical, food, agriculture, and by-products. Examples of materials include pesticides, veterinary drugs, disinfectants, laundry detergent, grains, seeds, milk powder, seasonings, monosodium glutamate, salt, sugar, additives, etc.

Product features:

Microcomputer control for accurate and adjustable quantitative filling. Parameters can be adjusted, and errors can be automatically corrected. Separation of strong and weak electric currents eliminates interference. It has high reliability and wide applicability. The filling parts are made of high-precision, interchangeable stainless steel with a reasonable classification. The modular design allows flexible combinations.

Large barrel water filling machine:

The large barrel water filling production line incorporates advanced production technology and processes from American companies, integrating the advantages of similar products from Italy, France, and other countries. It is an automated filling machine production line developed through technological improvements. This equipment is technologically advanced, reliable in performance, scientifically designed in process flow, and meets high food hygiene standards. It offers a high degree of automation, easy operation, and is an ideal filling equipment for beverage manufacturers, widely favored by the food and beverage industry.

The machine body is made of high-quality stainless steel, and other parts are made of non-toxic and durable composite materials. The electrical and pneumatic systems use imported components, resulting in low equipment failure rate and high reliability. The process flow includes automatic cap removal, automatic barrel brushing, automatic barrel loading, automatic washing and disinfection, automatic filling, automatic cap arranging, cap fitting, and capping, inspection by light, automatic shrink film packaging, and automatic bagging (including conveyor belt).

work process

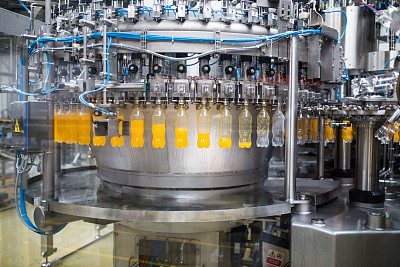

The general process of a liquid filling machine is as follows: Boxes filled with empty bottles are stacked on pallets and transported by a conveyor belt to the unloading palletizer. The pallets are unloaded one by one, and the boxes are sent to the unboxing machine through the conveyor belt. The empty bottles are taken out from the boxes, and the empty boxes are sent to the box washing machine through the conveyor belt for cleaning. After being thoroughly cleaned, the empty boxes are transported to the vicinity of the box packaging machine to be filled with the bottled beverages.

The empty bottles taken out from the unboxing machine are fed into the bottle washer through another conveyor belt for sterilization and cleaning. After passing through the bottle inspection machine and meeting the cleanliness standards, they are sent to the filling machine and capping machine. The beverages are filled into the bottles by the filling machine. Once the bottles are filled with the beverages, they are sealed with caps by the capping machine and then transported to the labeling machine for labeling. After the labels are applied, the bottles are sent to the box packaging machine to be placed into boxes and then delivered to the palletizer. Finally, the pallets with the boxed products are stacked on pallets and transported to the warehouse.

Instructions for use

Instructions for Use, Maintenance, and Installation

- As this filling machine is an automated device, it requires uniform sizes for the PET bottles, bottle caps, and bottle pads.

- Before starting the machine, rotate the handles manually to check for any abnormalities in the rotation. Only proceed with operation if everything is determined to be normal.

- When adjusting the machine, use appropriate tools. It is strictly prohibited to use tools that are too large or apply excessive force to dismantle components, as this may damage the parts or affect the machine's performance.

- After making adjustments to the machine, make sure to tighten any loosened screws. Rotate the handles manually to observe if the machine's movements meet the requirements before starting operation.

- The machine must be kept clean. It is strictly forbidden to have oil stains, medicine residues, or glass fragments on the machine to avoid damage. Therefore, the following measures must be taken: (a) During the production process, promptly remove any medicine residues or glass fragments. (b) Before shift change, clean the various surfaces of the machine and apply lubricating oil to the moving parts. (c) Perform a thorough cleaning at least once a week, paying particular attention to areas that are not easily cleaned during regular use. Use compressed air if necessary.

Disinfection and Cleaning

- Loosen the upper and lower fixing screws and dismantle the liquid injection system for overall disinfection, or dismantle and disinfect each part separately.

- Place the liquid inlet pipe in the cleaning solution and start the machine for cleaning.

- For the 500ml model, there may be discrepancies in actual filling. Before official filling, use a measuring cylinder to ensure accurate measurement.

- The filling machine uses a needle. Model 10 employs a standard 5ml or 10ml syringe, Model 20 uses a 20ml glass filler, and Model 100 uses a 100ml glass filler.

Installation Precautions

- After unpacking the machine, first check if all the provided technical documentation is complete and if the machine has suffered any damage during transportation in order to address any issues promptly.

- Install and adjust the feeding and discharging components according to the illustrated diagrams in this instruction manual.

- Apply fresh lubricating oil to each lubrication point.

- Rotate the handles manually to check if the machine rotates in the correct direction (facing the motor shaft counterclockwise). The machine must be properly grounded.

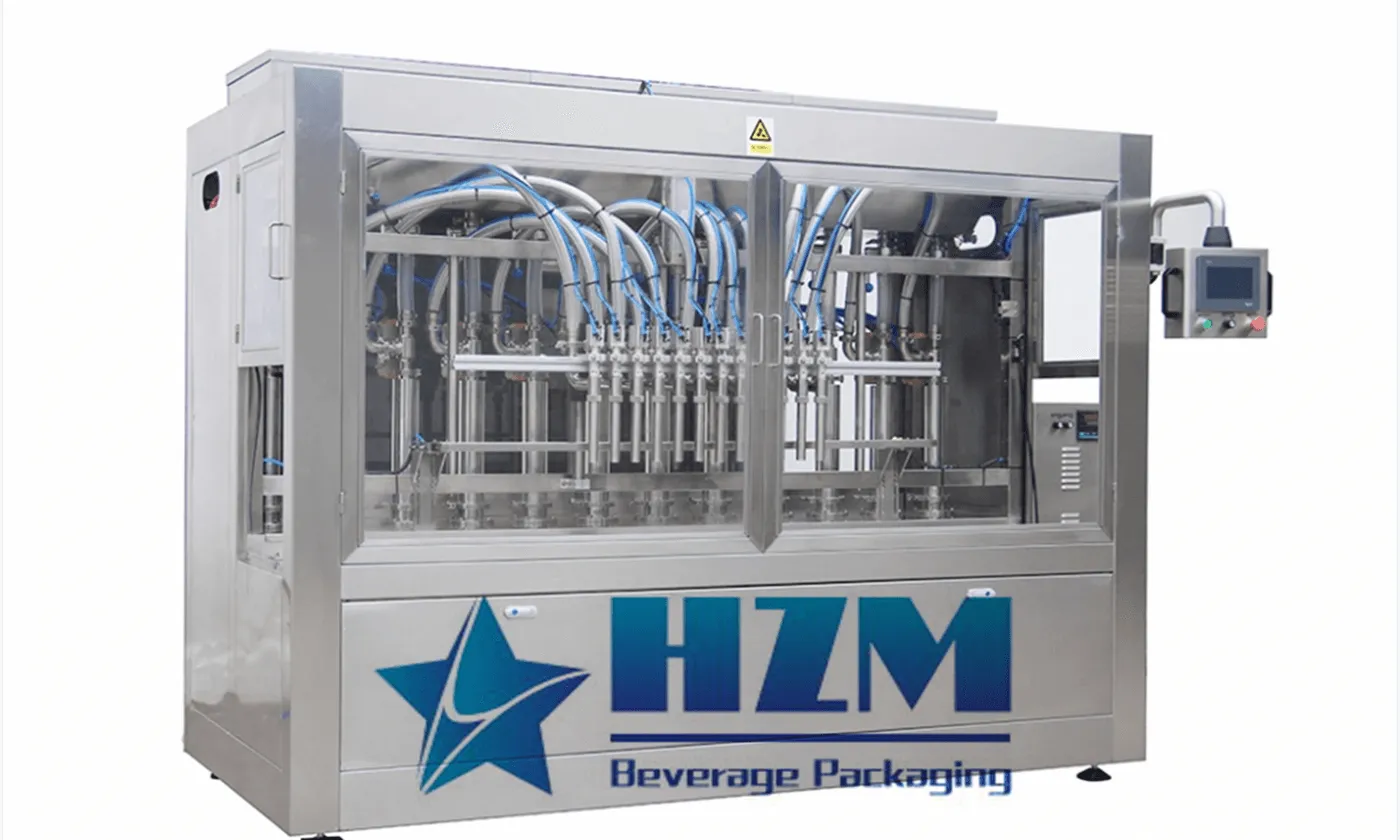

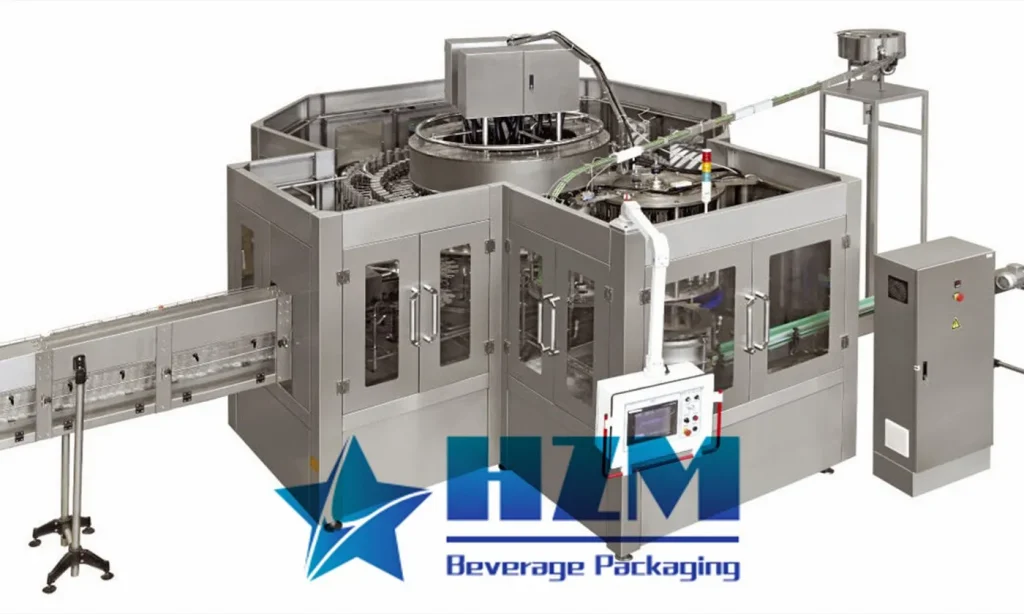

Choosing to purchase the HZM Filling Machine.

Why Choose HZM Mechanical Filling Machine?

- Superior Quality: Our machine is built with precision and craftsmanship, using premium-grade materials to ensure durability and long-lasting performance. It is designed to withstand demanding production environments, providing you with a reliable solution for years to come.

- Versatile Functionality: HZM Mechanical Filling Machine offers versatile functionality, allowing you to handle a wide range of products and containers. Whether you need to fill liquids, creams, or powders into bottles, jars, or tubes, our machine can efficiently accommodate your diverse packaging needs.

- Efficient Workflow: With its streamlined workflow, HZM Mechanical Filling Machine optimizes your production process, minimizing downtime and maximizing productivity. The automated features, such as bottle feeding, filling, and capping, ensure a smooth and continuous operation, saving you time and labor costs.

- Precision and Accuracy: Our machine incorporates advanced technology for precise and accurate filling. The adjustable settings allow you to control fill volumes with precision, ensuring consistent product quality and reducing product waste. Say goodbye to overfilling or underfilling issues!

- User-Friendly Interface: HZM Mechanical Filling Machine is designed with user convenience in mind. The intuitive interface and easy-to-use controls make it simple for operators to set up and operate the machine. Minimal training is required, enabling a quick integration into your production line.

- Reliable Customer Support: We pride ourselves on providing excellent customer support. Our dedicated team is always ready to assist you with any inquiries, technical support, or maintenance needs. We are committed to ensuring your satisfaction and the smooth operation of your filling machine.

Invest in HZM Mechanical Filling Machine today and experience a seamless packaging process that boosts your efficiency and product quality. Contact us now to learn more about our product, request a demonstration, and discuss how our filling machine can meet your specific requirements. Upgrade your packaging operations with HZM Mechanical Filling Machine and stay ahead of the competition!

TAG: Beverage Filling Machine Edible Oil Filling Machine Filling Machine filling machines Water Filling Machine

-

![Mono-block Filling Machine 3 in 1]() Mono-block Filling Machine 3 in 1

Mono-block Filling Machine 3 in 1 -

![Olive Oil Filling Machine]() Olive Oil Filling Machine

Olive Oil Filling Machine -

![Automatic Cooking Oil Filling Machine]() Automatic Cooking Oil Filling Machine

Automatic Cooking Oil Filling Machine -

![Edible Oil Filling Machine]() Edible Oil Filling Machine

Edible Oil Filling Machine -

![Linear Type Oil Filling Machine]() Linear Type Oil Filling Machine

Linear Type Oil Filling Machine -

![PET Bottle CSD Beverage Filling Machine]() PET Bottle CSD Beverage Filling Machine

PET Bottle CSD Beverage Filling Machine -

![Glass Bottle CSD Beverage Filling Machine]() Glass Bottle CSD Beverage Filling Machine

Glass Bottle CSD Beverage Filling Machine -

![CSD Beverage Can Filling Machine]() CSD Beverage Can Filling Machine

CSD Beverage Can Filling Machine -

![Carbonated Drinks Filling Machine]() Carbonated Drinks Filling Machine

Carbonated Drinks Filling Machine -

![PET Bottle Water Filling Machine]() PET Bottle Water Filling Machine

PET Bottle Water Filling Machine -

![3-10L Big PET Bottle Water Filling Machine]() 3-10L Big PET Bottle Water Filling Machine

3-10L Big PET Bottle Water Filling Machine -

![3-5 Gallon Water Filling Line]() 3-5 Gallon Water Filling Line

3-5 Gallon Water Filling Line -

![Automatic Water Bottle Filling Machine]() Automatic Water Bottle Filling Machine

Automatic Water Bottle Filling Machine

-

![Important Questions To Consider Before Purchasing Carbonated Filling Machine]() Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023

Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023 -

![How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?]() How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?Mar , 24 /2023

How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?Mar , 24 /2023 -

![Classification of beverage filling machines]() Classification of beverage filling machinesMar , 24 /2023

Classification of beverage filling machinesMar , 24 /2023 -

![Unveiling the Precision and Efficiency of Water Filling Machines]() Unveiling the Precision and Efficiency of Water Filling MachinesMar , 24 /2023

Unveiling the Precision and Efficiency of Water Filling MachinesMar , 24 /2023 -

![Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling Machine]() Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023

Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023 -

![How to choose the right filling machine?]() How to choose the right filling machine?Apr , 19 /2023

How to choose the right filling machine?Apr , 19 /2023 -

![What should be paid attention to when purchasing food-specific filling machines?]() What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023

What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023 -

![Comprehensive Service Solution for Glass Bottle Beverage Filling Equipment]() Comprehensive Service Solution for Glass Bottle Beverage Filling EquipmentApr , 23 /2023

Comprehensive Service Solution for Glass Bottle Beverage Filling EquipmentApr , 23 /2023 -

![Application of Juice Beverage Filling Machine in the Industry]() Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023

Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023 -

![Soft Drinks Sparkling Water Filling Machine: A Comprehensive Guide]() Soft Drinks Sparkling Water Filling Machine: A Comprehensive GuideApr , 26 /2023

Soft Drinks Sparkling Water Filling Machine: A Comprehensive GuideApr , 26 /2023 -

![How to Choose the Best Fully Automatic Edible Oil Filling Machine]() How to Choose the Best Fully Automatic Edible Oil Filling MachineMay , 04 /2023

How to Choose the Best Fully Automatic Edible Oil Filling MachineMay , 04 /2023 -

![Leading Manufacturer of Mineral Water Filling Machines]() Leading Manufacturer of Mineral Water Filling MachinesMay , 27 /2023

Leading Manufacturer of Mineral Water Filling MachinesMay , 27 /2023 -

![Your Trusted Manufacturer of Mineral Water Filling Machines]() Your Trusted Manufacturer of Mineral Water Filling MachinesJun , 06 /2023

Your Trusted Manufacturer of Mineral Water Filling MachinesJun , 06 /2023 -

![200-500ml Ultra-Clean Filling Machine]() 200-500ml Ultra-Clean Filling MachineJun , 09 /2023

200-500ml Ultra-Clean Filling MachineJun , 09 /2023 -

![Revolutionizing Beverage Production: The Ultimate Beverage Filling Machine]() Revolutionizing Beverage Production: The Ultimate Beverage Filling MachineJun , 27 /2023

Revolutionizing Beverage Production: The Ultimate Beverage Filling MachineJun , 27 /2023 -

![What is the Working Principle of 3 in 1 Water Filling Machine?]() What is the Working Principle of 3 in 1 Water Filling Machine?Jun , 27 /2023

What is the Working Principle of 3 in 1 Water Filling Machine?Jun , 27 /2023 -

![How much does an edible oil filling machine cost per unit, and how to choose the right one?]() How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023

How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023 -

![Edible Oil Bottle Filling Machine: Manufacturers and Pricing]() Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023

Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023 -

![Overview of Equipment for Edible Oil Filling Production Line]() Overview of Equipment for Edible Oil Filling Production LineSep , 25 /2023

Overview of Equipment for Edible Oil Filling Production LineSep , 25 /2023

Home /

Home /