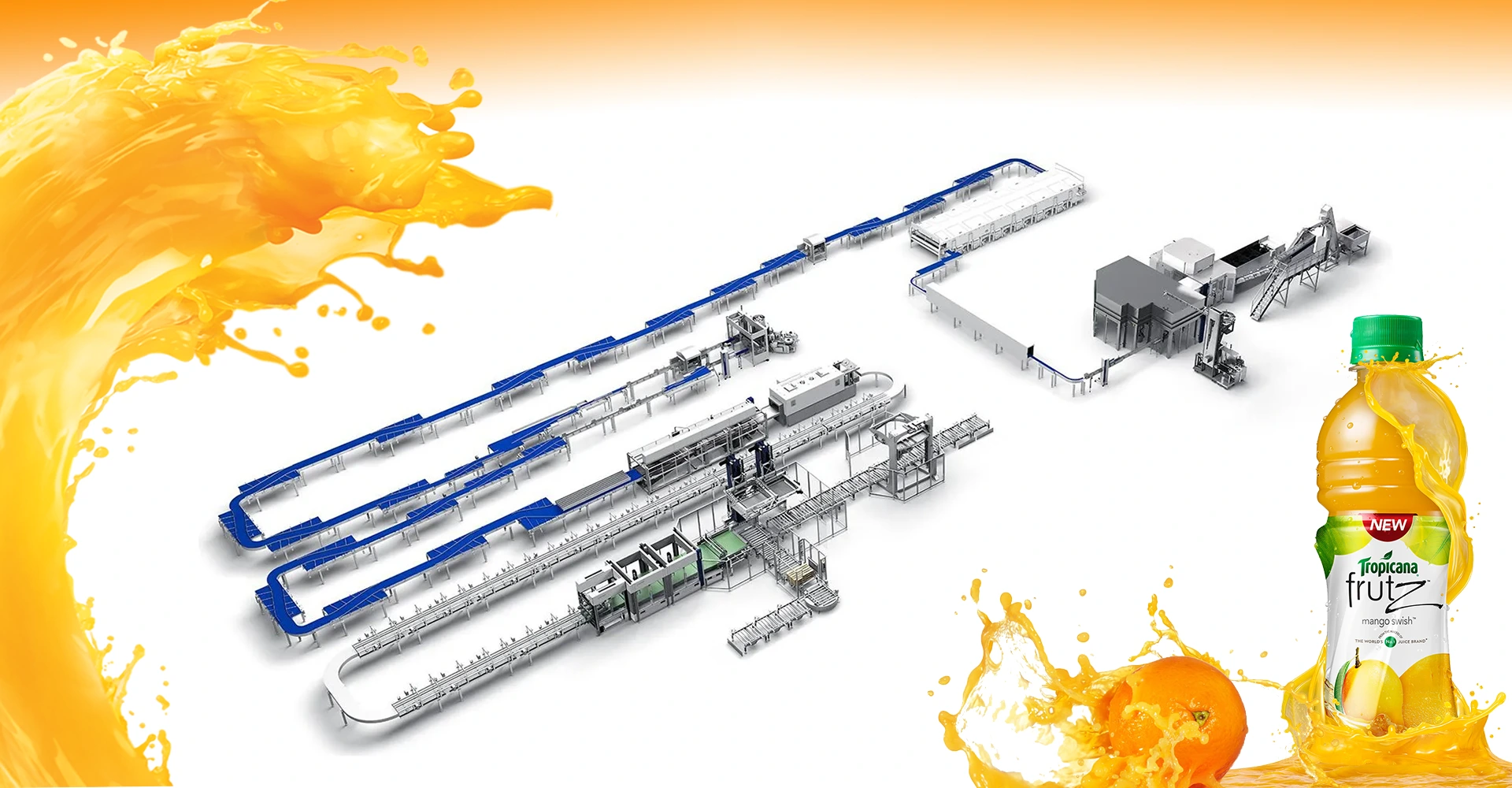

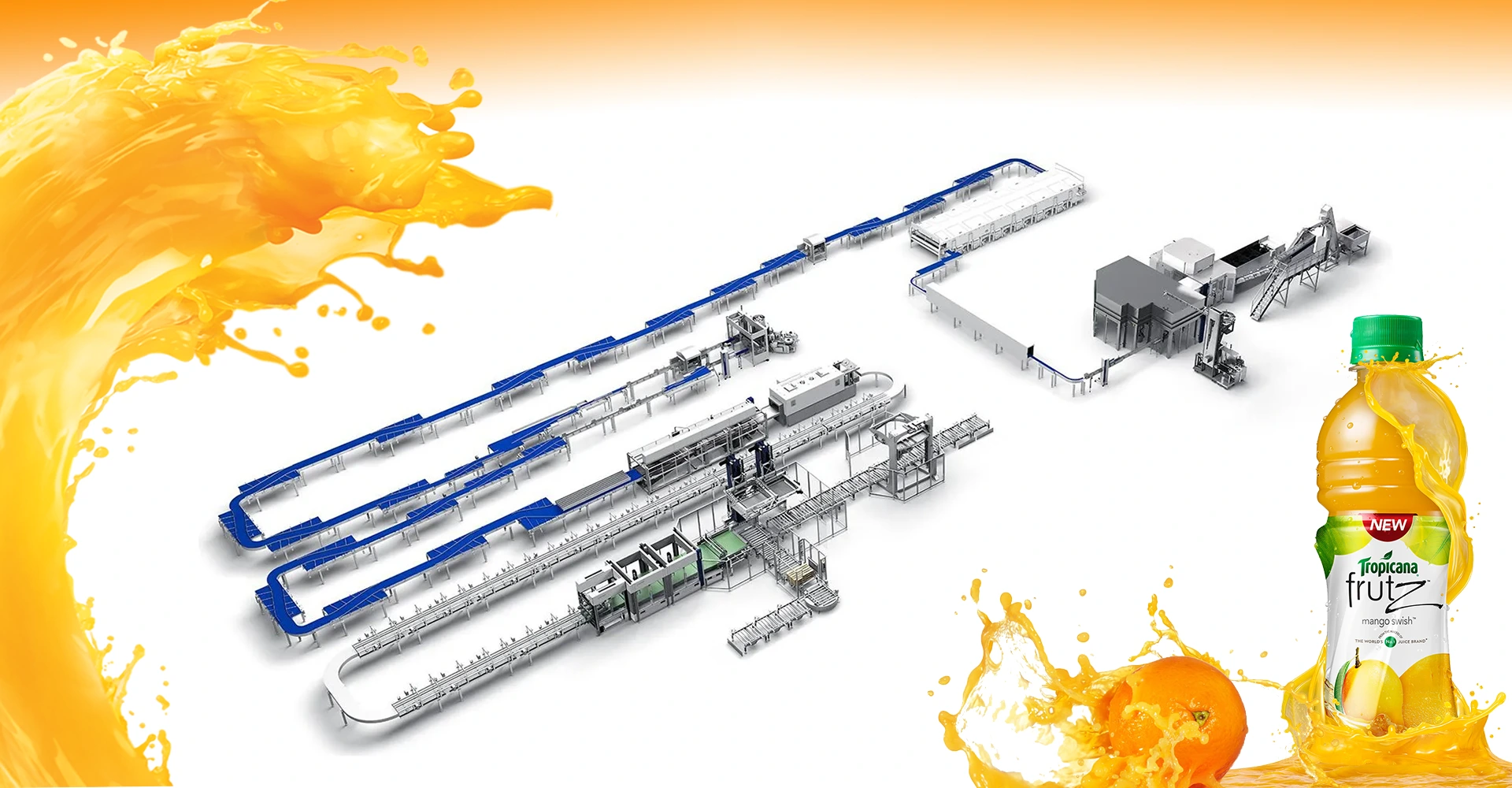

Essential Preparations for Beverage Production Line Installation

Preparing for the installation of a beverage production line is essential to ensure smooth setup and efficient operation. Here are some common preparatory steps:

1. Site Preparation

- Site Cleaning: Ensure the installation area is clean and free of any debris or obstructions.

- Leveling Check: Verify that the ground is level to prevent instability of the equipment after installation.

- Measurement: Measure the site dimensions according to the equipment layout requirements to ensure sufficient space for installation.

2. Supply of Water, Power, and Air

- Water Supply: Check the water pipes, ensure adequate water supply, and adjust water pressure according to the equipment's requirements.

- Power Supply: Prepare the appropriate power source and cables based on the equipment's power and voltage needs to ensure safe electricity usage.

- Air Supply: Verify that the air supply meets the equipment's pneumatic requirements (if air support is needed), including pressure and quality.

3. Equipment Verification and Inventory

- Component Check: Inventory all equipment parts to ensure nothing is missing.

- Visual Inspection: Check for any visible damage or wear on the equipment and report any issues to the supplier.

- Spare Parts: Ensure all essential spare parts are available for use during installation or future maintenance.

4. Preparation of Installation Drawings and Technical Documents

- Technical Drawings: Have installation drawings ready, including equipment layout, electrical wiring diagrams, and air supply layout.

- Technical Manuals: Familiarize yourself with the equipment user manual and operating instructions for later testing and operator training.

5. Personnel Arrangements

- Technicians: Arrange for experienced technicians to handle equipment installation and testing.

- Training: If it is new equipment, schedule training sessions for operators and maintenance staff to ensure smooth operation.

6. Scheduling and Progress Planning

- Installation Timeline: Set an appropriate timeline for installation to avoid unnecessary delays.

- Progress Schedule: Create a detailed installation progress plan, executing each step to ensure coordination between different phases.

7. Safety Measures

- Protective Measures: Provide necessary protective equipment for installation, such as helmets, safety glasses, etc.

- Safety Inspection: Ensure the installation environment meets safety standards to prevent accidents.

Following these steps will help ensure a smooth installation of the beverage production line and support stable and efficient production in the future.

TAG: Beverage Filling Machine Beverage Production Line

Update:2024-11-04

Author:HZM Machinery

Pageviews:1013

Our Product Range

Water treatment system

Beverage processing system

Blow molding machine

Filling machine

--Cans Filling Machine

--Carbonated Filling Machine

--Juice Filling Machine

--Oil Filling Machine

--Water Filling Machine

--Condiment Filling Machine

--Daily Chemical Liquid Filling Machine

Labeling machine

Packaging machine

Packs, Bottle Conveyors Machine

Related Products

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?