Daily Maintenance Tips for Edible Oil Filling Machines

In the filling machinery industry, especially for edible oil filling machines, the application of automation technology, intelligent technology, and information technology has become very common. Various types of automatic filling machines, semi-automatic filling machines, and fully automatic filling machines can be seen busy in various corners of the industry. They create one miracle after another for our lives and economic development, promoting China's economic development and progress. But have we done enough for the daily maintenance and upkeep of these machines?

Firstly, since the edible oil filling machine is mainly used for the packaging of various oil products, maintenance mainly involves keeping the machine and the working environment clean and hygienic to avoid direct or indirect contamination of the product. Before and after operation, the machine must be cleaned inside and outside, and parts that have been in contact with food must be strictly disinfected.

Secondly, during the maintenance of the edible oil filling machine, special attention should be paid to the fact that when conducting maintenance checks, the circuit breaker should be cut off or the power plug should be unplugged to prevent electric shock, burns, and injuries during the check. Also, the compressed air pressure of the edible oil filling machine should be reduced to zero, and it must be confirmed that the pressure has dropped to zero before disassembling the components on the compressed air side. This ensures the normal operation of the edible oil filling machine, ensures that the enterprise's production is not affected, and also effectively extends the service life of the filling machine.

Thirdly, it is necessary to check once a month whether the parts of the edible oil filling machine rotate flexibly and whether they are worn. Any defects found should be repaired in a timely manner, and forced use is not allowed. If the machine is not used for a long time, it must be wiped and cleaned thoroughly, and the smooth parts of the machine should be coated with rust-proof oil, covered with cloth, and prepared for the next use.

Edible oil filling machines are like people. If they work for a long time without replenishing energy or without proper rest, they will also have faults. Therefore, it is necessary to regularly maintain and upkeep filling machines to ensure their high work efficiency and long service life.

TAG: Edible Oil Filling Machines Filling Machine

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine Manufacturer

Drinking water production line – Bottled Water Filling Machine Manufacturer -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer

Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling Machine

Fully Automatic Beverage Filling Machine -

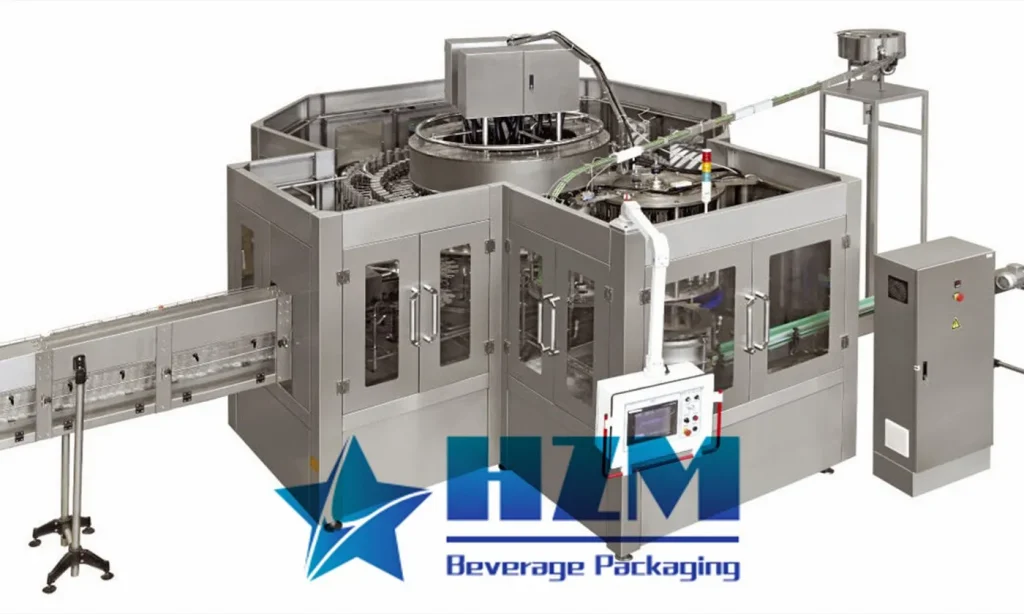

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

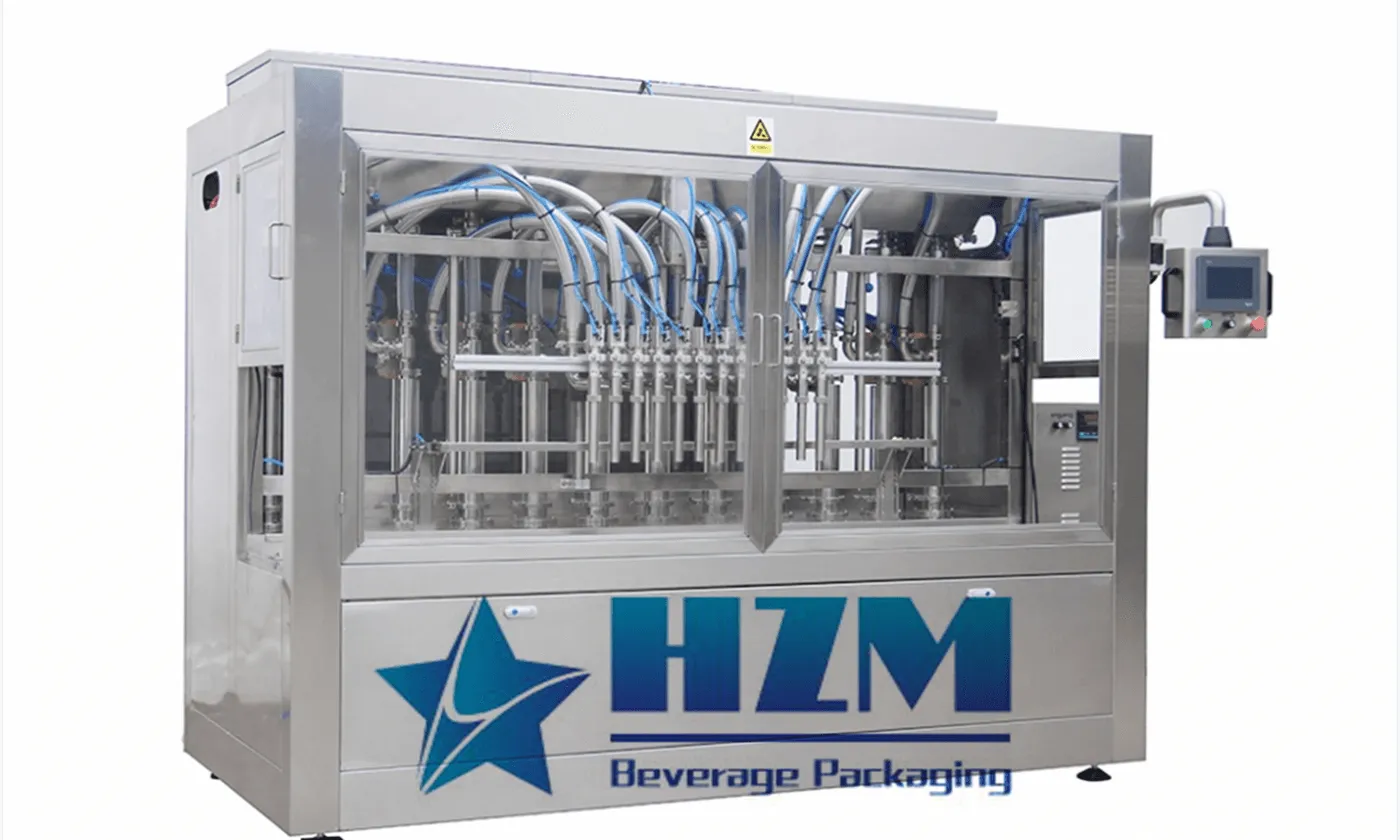

![Linear Type Oil Filling Machine]() Linear Type Oil Filling Machine

Linear Type Oil Filling Machine -

![PET Bottle Water Filling Machine]() PET Bottle Water Filling Machine

PET Bottle Water Filling Machine -

![3-10L Big PET Bottle Water Filling Machine]() 3-10L Big PET Bottle Water Filling Machine

3-10L Big PET Bottle Water Filling Machine -

![3-5 Gallon Water Filling Line]() 3-5 Gallon Water Filling Line

3-5 Gallon Water Filling Line -

![Automatic Water Bottle Filling Machine]() Automatic Water Bottle Filling Machine

Automatic Water Bottle Filling Machine

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025 -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025

Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025 -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025

Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025 -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling MachineDec , 21 /2023

Automatic Pure Water Bottling Filling MachineDec , 21 /2023 -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling MachineOct , 11 /2023

Fully Automatic Beverage Filling MachineOct , 11 /2023 -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling MachineOct , 10 /2023

3-In-1 Water Bottle Filling MachineOct , 10 /2023 -

![How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?]() How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?Mar , 24 /2023

How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?Mar , 24 /2023 -

![How to choose the right filling machine?]() How to choose the right filling machine?Apr , 19 /2023

How to choose the right filling machine?Apr , 19 /2023 -

![What should be paid attention to when purchasing food-specific filling machines?]() What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023

What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023 -

![Comprehensive Service Solution for Glass Bottle Beverage Filling Equipment]() Comprehensive Service Solution for Glass Bottle Beverage Filling EquipmentApr , 23 /2023

Comprehensive Service Solution for Glass Bottle Beverage Filling EquipmentApr , 23 /2023 -

![How much does an edible oil filling machine cost per unit, and how to choose the right one?]() How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023

How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023 -

![Why Durability Is Highly Valued in Fully Automatic Edible Oil Filling Machines?]() Why Durability Is Highly Valued in Fully Automatic Edible Oil Filling Machines?Oct , 14 /2023

Why Durability Is Highly Valued in Fully Automatic Edible Oil Filling Machines?Oct , 14 /2023 -

![What is an edible oil filling machine?]() What is an edible oil filling machine?Oct , 22 /2023

What is an edible oil filling machine?Oct , 22 /2023