How to Choose the Best Fully Automatic Edible Oil Filling Machine

With the continuous progress of human civilization, people are paying more and more attention to the safety of edible oil. This has gradually shifted people's focus from the safety of edible oil itself to the safety of its packaging, resulting in greatly increased requirements for the cleanliness of edible oil filling. So, in the edible oil packaging process, which parts will affect its quality? In order to summarize how to achieve hygienic filling, we need to examine the production process of the fully automatic edible oil filling machine first.

The production process of the fully automatic edible oil filling machine:

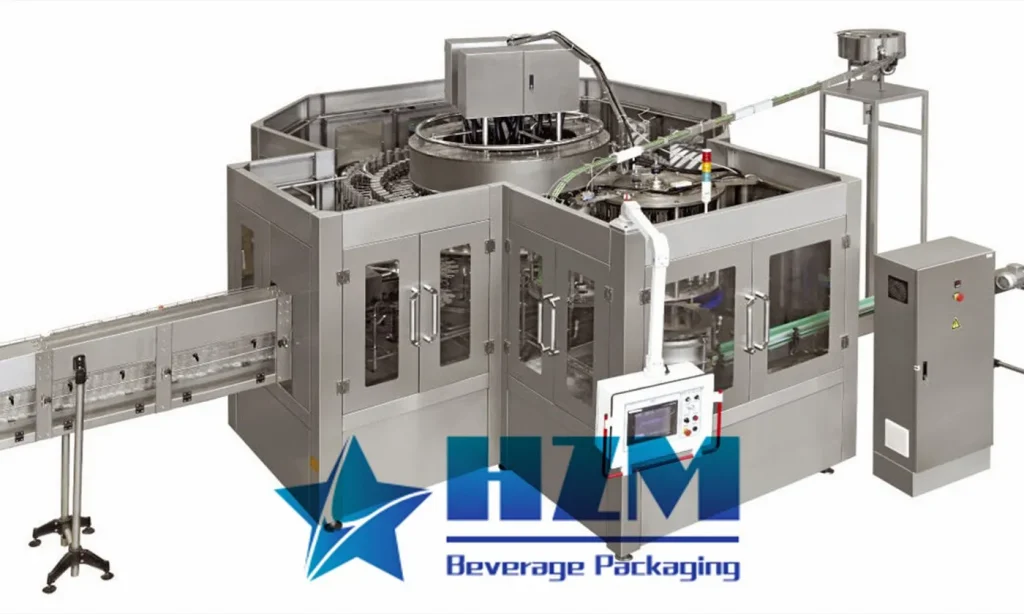

Firstly, edible oil needs a clean and sterile container to hold it, which can be blown out by the blowing machine in the fully automatic edible oil filling machine, or can be ordered separately. However, in terms of hygiene, the former without transportation is naturally cleaner.

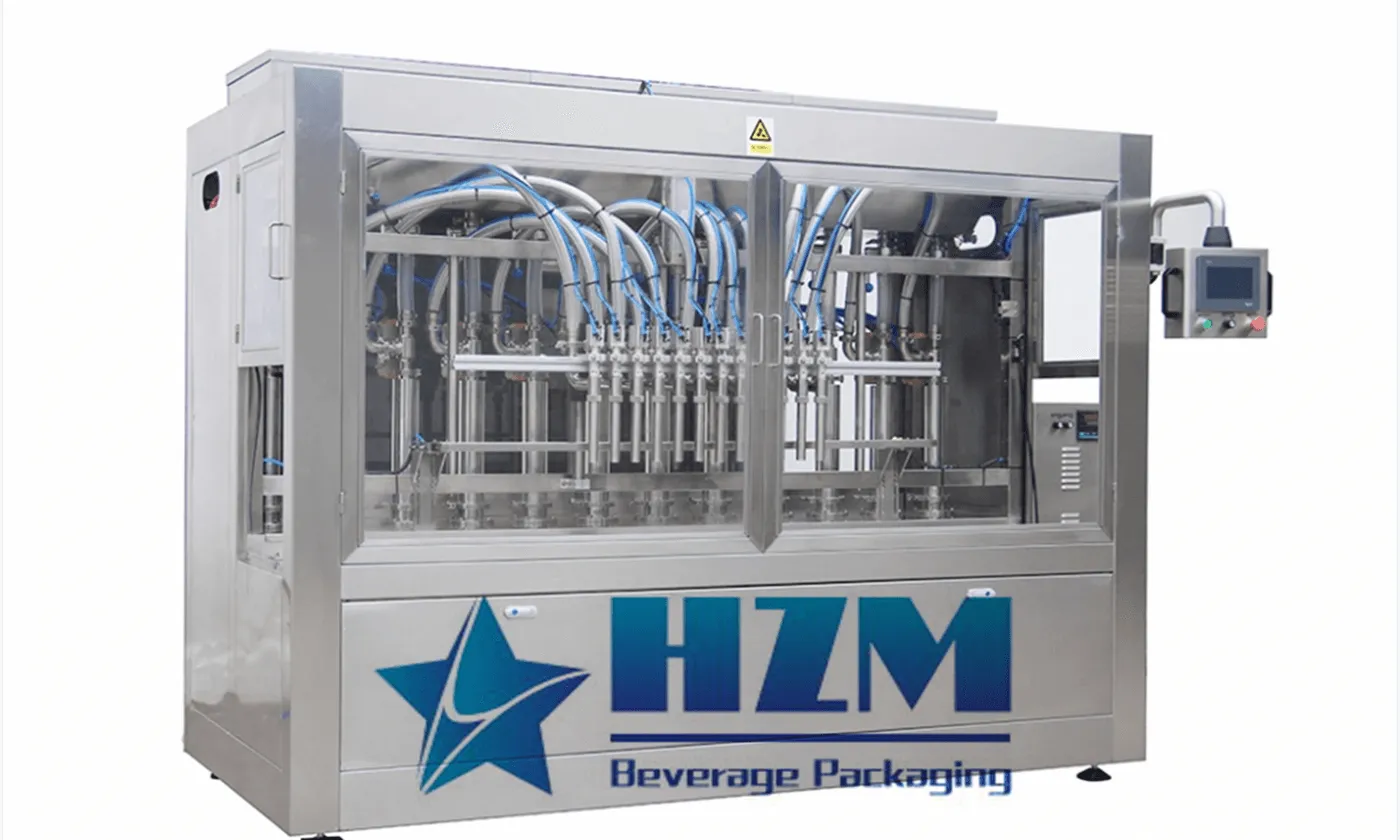

After arranging the containers, it comes to the part of filling the edible oil. In this process, high-precision quantitative filling should be realized to avoid backflow, overflow, and residue. The final step is to spin the cap of the filled edible oil. When spinning the cap, attention should also be paid to whether the bottle cap is clean, sterile, and free of impurities and dust.

From the filling steps, in order to ensure the pure and hygienic packaging of edible oil, it is necessary to choose a more reliable fully automatic edible oil filling machine. But where to start? This article will inspire you from five aspects on how to choose the best fully automatic edible oil filling machine.

How to choose the best fully automatic edible oil filling machine?

Here, cost-effectiveness refers to purchasing a liquid automatic filling machine with high efficiency, durability, and multiple functions within a certain price range, rather than just a low price. While low-priced machines are tempting, can their quality, efficiency, and durability be guaranteed? Sacrificing product and output for low prices is a shortsighted behavior. Moreover, a machine that is relatively expensive but with high efficiency and complete functions can recover costs after a certain period of operation.

Due to food safety concerns, the filling machine selected should have a certain degree of sealing and hygiene. This requires minimizing human operations as much as possible during the entire packaging process, avoiding external pollution. At the same time, the machine needs to be able to automatically clean the internal pipeline, promptly handle edible oil residues, and maintain cleanliness throughout the production process.

Choosing a reliable fully automatic filling machine manufacturer can usually save you time in selecting and avoid the tedious and annoying task of obtaining information from various channels and then comparing them based on the above conditions. A well-known brand in the liquid packaging industry usually has a certain number of years of operation and can provide you with targeted solutions based on accumulated rich experience, bringing you intimate service.

TAG: Automatic Edible Oil Filling Machine Edible Oil Filling Machine Filling Machine

-

![How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?]() How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?Mar , 24 /2023

How to Solve the Problem that the Liquid Filling Machine is not Fill Correctly?Mar , 24 /2023 -

![How to choose the right filling machine?]() How to choose the right filling machine?Apr , 19 /2023

How to choose the right filling machine?Apr , 19 /2023 -

![What should be paid attention to when purchasing food-specific filling machines?]() What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023

What should be paid attention to when purchasing food-specific filling machines?Apr , 21 /2023 -

![Comprehensive Service Solution for Glass Bottle Beverage Filling Equipment]() Comprehensive Service Solution for Glass Bottle Beverage Filling EquipmentApr , 23 /2023

Comprehensive Service Solution for Glass Bottle Beverage Filling EquipmentApr , 23 /2023 -

![Filling Machine, Classification, Workflow, Instructions for Use, Procurement]() Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023

Filling Machine, Classification, Workflow, Instructions for Use, ProcurementJun , 19 /2023 -

![How much does an edible oil filling machine cost per unit, and how to choose the right one?]() How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023

How much does an edible oil filling machine cost per unit, and how to choose the right one?Aug , 03 /2023 -

![Edible Oil Bottle Filling Machine: Manufacturers and Pricing]() Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023

Edible Oil Bottle Filling Machine: Manufacturers and PricingSep , 21 /2023 -

![Overview of Equipment for Edible Oil Filling Production Line]() Overview of Equipment for Edible Oil Filling Production LineSep , 25 /2023

Overview of Equipment for Edible Oil Filling Production LineSep , 25 /2023

Home /

Home /