Easy Operate 500ml Aerated Juice Glass Bottling Machine

| Material: | Stainless Steel | Process: | Pressure Filling System |

|---|---|---|---|

| Certification: | GB/T19001-2000 | Type: | Filling Machine |

| Capacity: | 8000 Bottles/hour---36000 Bottles/hour (500ml) | Bottle Height (mm): | 180-315 |

| Bottle Volume (ml): | 200ml-750ml | Remark: | All-in-one Type |

| High Light: | 500ml Glass Bottling Machine, 1500ml Glass Bottling Machine, 500ml aerated juice Bottling Machine | ||

Easy Operate 500ml Aerated Juice Glass Bottling Machine

Bottle Filling Machine Ampoule Pharmaceutical Bottle Forming Filling And Sealing Machine

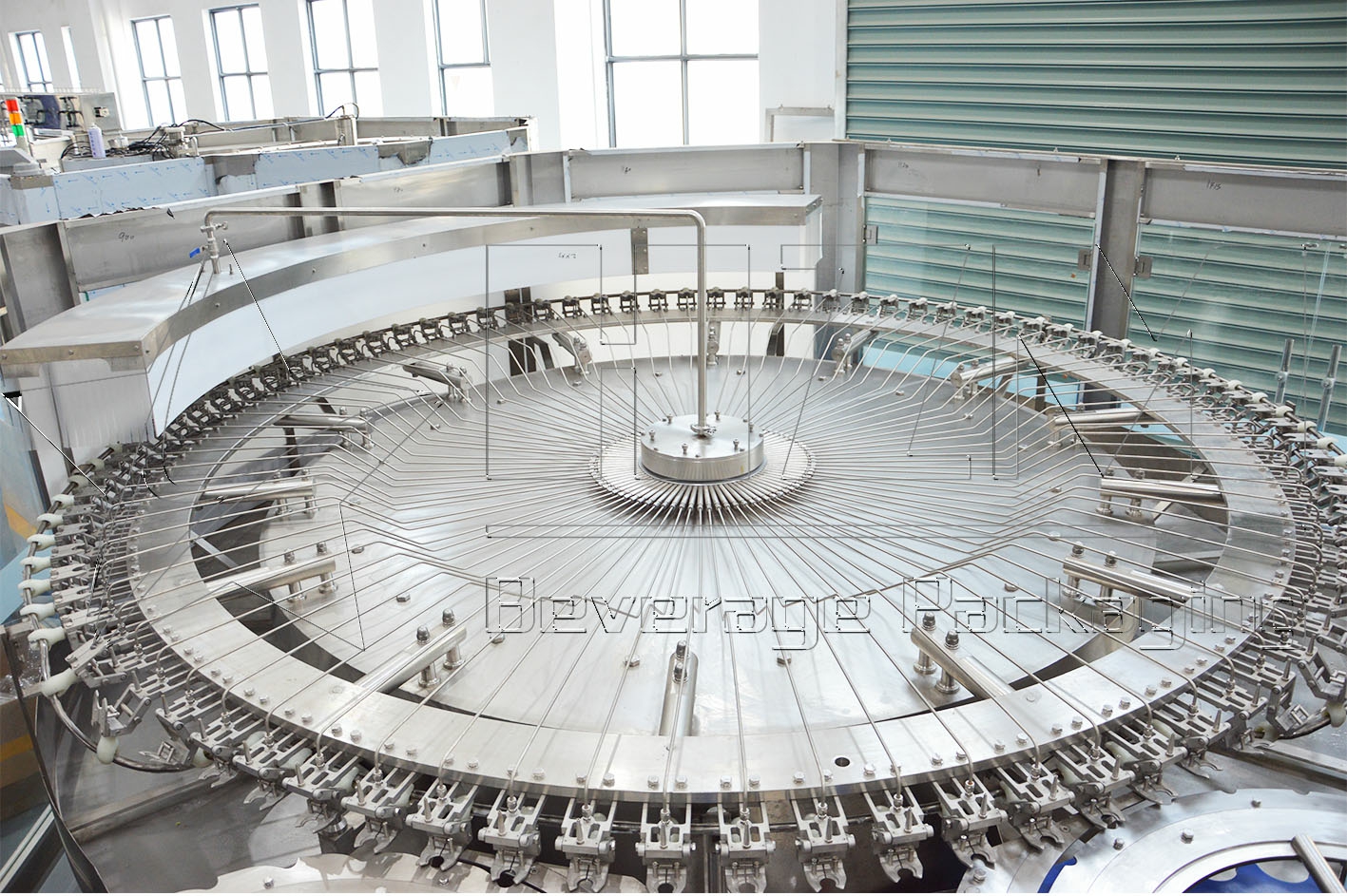

Our bottled water filling machine is an automatic liquid packaging machine that combines a bottle washing machine, a pressure filling machine and a capping machine. We provide you with some information about how bottled water bottlers work. The air conveyor transports the empty bottle to the washing machine in an orderly manner, then turns the bottle over and cleans the inside of the bottle through the nozzle. After dropping the bottle, it is automatically sent to the filling machine to fill the liquid at high speed, and these bottles are covered safely and reliably by the capping machine.

Specifications

Glass bottle steam filling machine

Capacity: A-15000 bottles/hour ----54000 bottles/hour (500ml)

Applicable bottle type: 200ml-1500ml

Filling valve: According to customer needs, use equal pressure mechanical valve/imported flow meter valve

Applicable products: high-end aerated mineral water, aerated soda water, cola, sprite, aerated juice

Specifications of Bottled Water Filling Machine

|

Model |

Number of Bottle Rinsing Clip |

Number of Filling Valve |

Number of Capping Head |

Capacity (bpm) |

Bottle Size |

Dimensions (mm) |

Weight (Kg) |

Remark |

||

|

Diameter (mm) |

Height (mm) |

Volume (ml) |

||||||||

|

DGY06 |

18 |

18 |

6 |

8000 |

Φ60-Φ96 |

180-315 |

350-1500 |

2480x1980x2600 |

4000 |

All-in-one Type |

|

DGY08 |

24 |

24 |

8 |

12000 |

Φ60-Φ96 |

180-315 |

350-1500 |

2800x2400x2600 |

6000 |

All-in-one Type |

|

DGY10 |

32 |

32 |

10 |

16000 |

Φ60-Φ96 |

180-315 |

350-1500 |

3300x3000x2700 25002500 3085 |

7200 |

All-in-one Type |

|

DGY12 |

40 |

40 |

12 |

20000 |

Φ60-Φ96 |

180-315 |

350-1500 |

3900x3180x2700 |

9000 |

All-in-one Type |

|

DGY15 |

50 |

50 |

15 |

24000 |

Φ60-Φ96 |

180-315 |

350-1500 |

5300x4200x2900 |

10000 |

All-in-one Type |

|

DGY15 |

60 |

60 |

15 |

28000 |

Φ60-Φ96 |

180-315 |

350-1500 |

5700x4600x2900 |

12000 |

All-in-one Type |

|

DGY18 |

72 |

72 |

18 |

32000 |

Φ60-Φ96 |

180-315 |

350-1500 |

6600x5100x2900 |

15000 |

All-in-one Type |

Features

All parts in contact with liquid are manufactured by quality stainless steel, for example, the filling valves are made of stainless steel 316.

The use of pressure type filling system helps ensure high filling speed, precision and quality.

Our bottled water filling machine uses advanced "PICK, PLACE" capping system with magnetic clutch capping head for reliable capping and convenient magnetic torque adjustment.

Due to the adoption of frequency conversion motor+PLC+MMI, the capacity, shift production and failure alarm could be displayed on the screen for ease of operation.

Quality Control

To guarantee the excellent performance of our beverage production lines and beverage machinery, we introduce advanced technology from Germany and Italy, and constantly improve our production technology of liquid filling. Apart from that, free trainings are offered to our employees to help them improve technical skills. In addition, we strongly believe that beverage production lines and beverage machines with high pass rate and reliable quality can effectively reduce production cost. Thus, we strictly implement product inspection in every step of production, from raw material acquisition to shipping our finished products, to ensure the quality and pass rate. Besides, much attention is also placed on perfect management system and high quality employees for a higher working efficiency.

As a bottled water filling machine with decades of experience, we at HZM also provide flesh fruit grain beverage filling line, automatic depalletizer, wrapping case packer etc., in addition to water filling machine. If you do not find the product you are looking for, we can customize our beverage machinery according to your specific requirements. As a result of our high quality products and dependable service, we have been awarded the ISO9001:2000 certificate.

Apart from water filling machines, we also produce degassers, beverage mixers, tea drink production lines, can production lines etc. to suit your various needs. Additionally, we can customize our beverage production lines according to customers' specific requirements. With the advantage of superior reliability, safety and durability, our products are in increasing demand in the USA, Canada, Britain, Mexico, Japan .

TAG: 1500ml Glass Bottling Machine 500ml aerated juice Bottling Machine 500ml Glass Bottling Machine Glass Bottle Filling Machine

-

WhatsApp/Tel : +8613915693104

-

Email : [email protected]

-

Email : [email protected]

-

Address : Machinery Industry Park of Jinfeng Town, Suzhou City, Jiangsu, China

© 2023 HZM Machinery Co., Ltd. All Rights Reserved

Submitted successfully

We have received your message and will get in touch with you as soon as possible to provide you with the corresponding service

Home /

Home /