Detailed Process of Food and Beverage Packaging

The process of food and beverage packaging encompasses the entire process of packaging, including the preparation of raw materials, the selection and configuration of packaging equipment, and the various steps involved in packaging operations. The following is a detailed process of food and beverage packaging.

I. Preparation of Raw Materials

Raw materials for food and beverage packaging include packaging materials such as plastic bottles, paper cartons, aluminum foil, and the food and beverage products themselves. Before preparing raw materials, it is essential to choose suitable packaging materials based on product characteristics and packaging requirements, followed by quality inspection to ensure safety and quality.

II. Selection and Configuration of Packaging Equipment

Select appropriate packaging equipment such as filling machines, labeling machines, and sealing machines based on product characteristics and packaging requirements. When acquiring equipment, considerations include production scale, product variety, and packaging speed. Thorough communication and negotiation with equipment suppliers are essential to ensure the adaptability and stability of the selected equipment.

III. Packaging Operations

- Preparatory Work: Inspect and maintain packaging equipment, clean the operating area to ensure hygiene.

- Packaging Preparation: Ensure all selected packaging materials, such as plastic bottles and paper cartons, are prepared. Depending on packaging requirements, prepare the necessary packaging containers and auxiliary materials, such as bottle caps, labels, and tapes.

- Packaging Operation Steps:

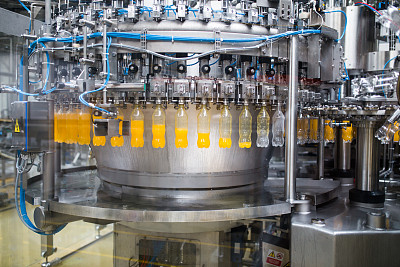

- Filling: Pour the food and beverage into the packaging containers, either manually or using an automatic filling machine.

- Sealing: Based on the container type and sealing method, perform sealing operations, such as using a capping machine for plastic bottles or a bottom-sealing machine for paper cartons.

- Labeling: Affix product labels according to packaging requirements, either manually or using a labeling machine.

- Inspection: Conduct visual inspections and quality checks on the packaged food and beverages to ensure they meet the required standards.

IV. Post-Packaging Processing

Store, transport, and sell the packaged food and beverages. During storage, maintain environmental cleanliness and temperature control to ensure product quality. Implement appropriate packaging protection measures during transportation to prevent packaging damage and product leakage. Display products in dry, well-ventilated environments during sales for easy customer selection and consumption.

V. Quality Control and Safety Supervision

Quality control and safety supervision are crucial aspects of the packaging process:

- Pre-Packaging Preparation: Inspect and control the quality of packaging materials, clean and disinfect equipment, and understand product characteristics and packaging requirements.

- Hygiene Control: Ensure cleanliness and hygiene in the operating area, including work surfaces, tools, and containers. Pay special attention to the hygiene performance of materials and equipment that come into contact with food and beverages. Regularly clean and disinfect equipment to prevent contamination.

- Sampling and Testing: Conduct sampling and testing during the packaging process, including visual inspections, packaging integrity checks, capacity measurements, and seal integrity tests to ensure that no quality issues occur during packaging. Record the test results and compare them with relevant standards.

- Material Traceability: Maintain records and manage the source and usage of raw materials, facilitating quick tracing of problematic products and recalls to protect consumer rights and the company's reputation.

- Safety Supervision: Government regulatory authorities should regularly inspect companies and monitor the quality of packaged products. Conduct checks and sampling tests, strengthen equipment registration, and supervision to prevent the use of low-quality and non-compliant equipment.

VI. Environmental Protection and Sustainable Development

Focus on environmental protection and sustainable development throughout the packaging process:

- Energy Conservation: Choose energy-efficient equipment, schedule production plans rationally to reduce equipment idling and standby time, and improve energy utilization efficiency. Regularly inspect and maintain equipment to ensure normal operation and avoid energy waste.

- Waste Reduction: Control the generation of waste during packaging by optimizing packaging design, reducing the amount of packaging material used. Classify and recycle waste, such as paper cartons and plastic bottles. Reuse or resourcefully treat waste to reduce environmental pollution.

- Use of Renewable Materials: Prioritize the use of renewable packaging materials, such as biodegradable materials and recyclable materials, to reduce dependence on non-renewable resources. Pay attention to the environmental friendliness and sustainability of packaging materials, avoiding the use of environmentally harmful materials.

- Promotion of Green Packaging: Promote green packaging by incorporating eco-friendly designs, such as reducing packaging layers and utilizing biodegradable materials. Additionally, advocate for green packaging certification and standards to guide consumers in choosing environmentally friendly products.

In conclusion, the food and beverage packaging process is a complex and rigorous procedure that requires careful planning and implementation. Quality control and safety supervision are crucial for ensuring product quality and safety, while the principles of environmental protection and sustainable development should be integrated throughout the entire packaging process to reduce energy consumption, waste, and environmental pollution. Only by tightly combining quality and environmental protection can sustainable development in food and beverage packaging be achieved.

TAG: Beverage Packaging Machine Beverage Packaging Production Line

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?