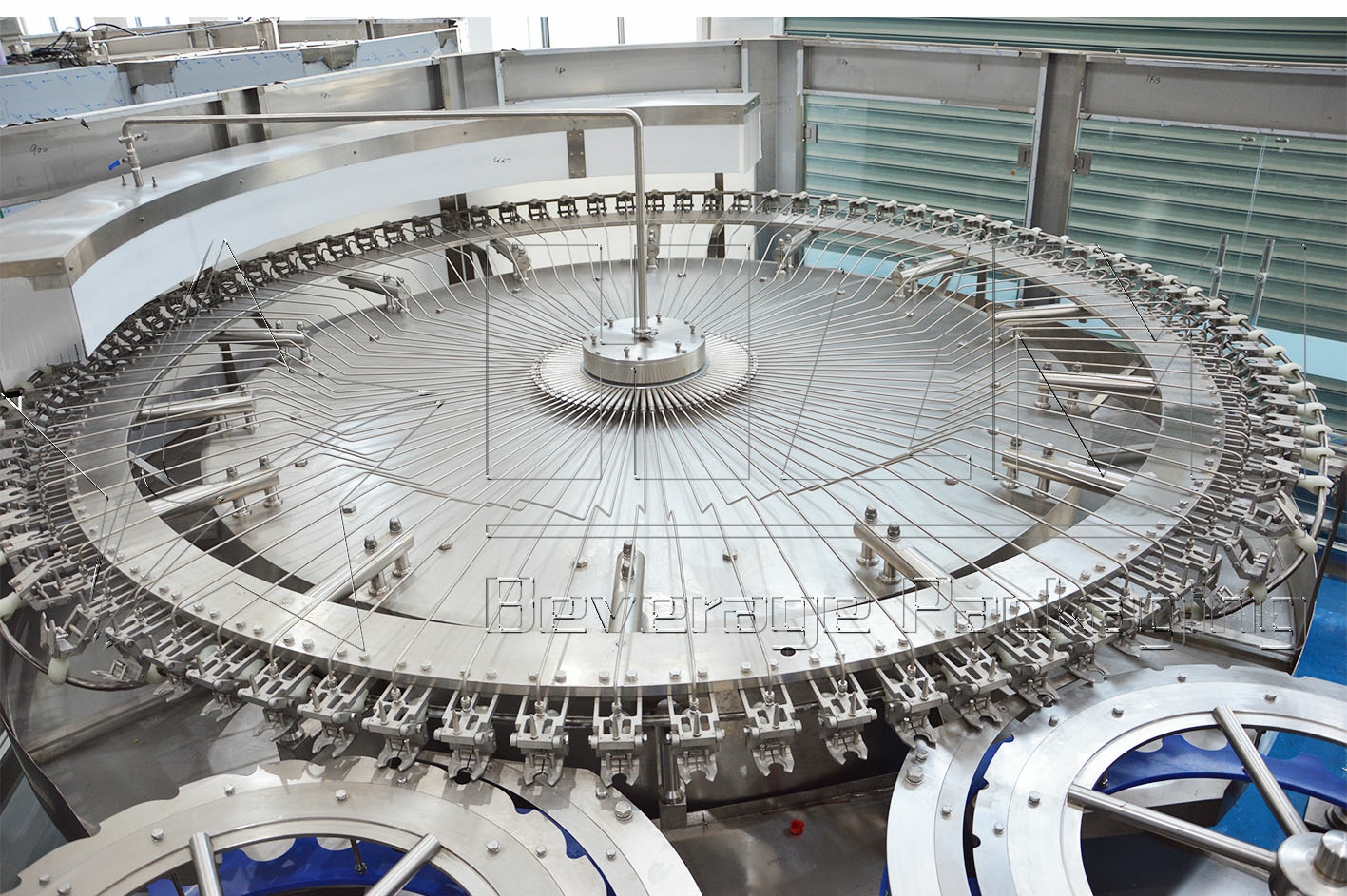

Contactless Aseptic Bottle Milk Filling Machine

| Material: | Stainless Steel | Process: | Gravity Filling System |

|---|---|---|---|

| Certification: | GB/T19001-2000 | Type: | Filling Machine |

| Filling Valve: | Gravity Mechanical Valve Or Customer Needs | Capacity: | 12000-48000bph |

| Applicable Bottle Type: | 200ml-1500ml | Application: | Milk Beverage |

| Function: | Milk Beverage Filling Machine | ||

| High Light: | PLC Milk Bottle Packing Machine, PLC Aseptic Bottle Packing Machine, Contactless Milk Bottle Filling Machine | ||

Contactless Aseptic Bottle Milk Filling Machine

Specifications

Packaging bottle: PET outsourcing bottle or PP bottle

Bottle cap: anti-theft cap

Filling valve: aseptic filling valve, non-contact filling

Applicable products: Pasteurized milk, active probiotics, fermented yogurt and other cold chain products.

Applicable capacity: 8000-48000BPH (500ml)

Characteristic

1. Intelligent contact screen, human design, easy operation.

2. High speed filling valve, avoiding drop leaking, accurate filling quantity.

3. Program logic controller(PLC), easy for changing size or modifying parameters.

4. Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

5. Pneumatic executive control valve, high efficiency and safety.

6. Close positioning design, easy governing, suitable for packing of all sizes of bottles.

7. Machine is designed according to requirements of buyer's.

Quality Control

In order to ensure the excellent performance of our beverage production line and beverage machinery, we have introduced advanced technology from Germany and Italy, and continue to improve our liquid filling production technology.

We also provide free training to employees to help them improve their technical skills.

In addition, we firmly believe that beverage production lines and beverage machines with high qualification rate and high quality can effectively reduce production costs.

Therefore, we strictly implement product inspections in every production link from the acquisition of raw materials to the shipment of finished products to ensure quality and pass rate. In addition, the sound management system and high-quality employees have also attracted a lot of attention to improve work efficiency.

FAQ

Q: What are the Primary Products of Your Company?

A: Our products mainly include water production line, juice production line, tea production line, water filling machine, juice filling machine, tea filling machine, and more.

Q: Where is Your Beverage Machinery Applied to?

A: Our beverage production lines are extensively used for packaging of water, fruit juice, tea drinks, milk beverage, juice with grains, sodas, protein beverages, energy drinks, and more.

Q: What are the Properties of Your Beverage Production Lines?

A: Our beverage machinery adopts automatic operation system which greatly improves the performance and productivity of our packaging machines. They have properties of multifunction, standard design, modularization, digital control system, good compatibility, high accuracy, flexibility, and high working efficiency.

All these measures together enable us to provide high quality carbonated beverage production lines, can filling machines, juice production lines, tea filling machines, etc, at competitive prices.

Q: What Kind of After-sale Services does Your Company Provide?

A: Installation guides, device debugging and technical trainings are offered to our global customers to help them make full use of our water production lines, tea filling machines, beverage production lines, and other beverage machinery.

TAG: Contactless Milk Bottle Filling Machine Milk Filling Machine PLC Aseptic Bottle Packing Machine PLC Milk Bottle Packing Machine

Home /

Home /