Comprehensive Overview of Pasteurization Production Line Applications, Processes, Operation, and Safety Measures

The application of the pasteurization production line is extremely extensive in our daily life, and it is suitable for the sterilization of vacuum-packed foods, low-temperature meat products, ham sausages, sausages, fruits, fruit juices, vegetable juices, pickled vegetables, pickled vegetables, salted vegetables, pickled vegetables, radishes, pickles, pickles, wild vegetables, jams, jellies, bean products, etc., as well as the sterilization of vacuum-packed foods, flexible tube and bottle packaging materials, and glass bottle packaging materials.

- Scope of Application of Pasteurization Production Line

The pasteurization production line is suitable for the sterilization of vacuum-packed foods, low-temperature meat products, ham sausages, sausages, fruits, fruit juices, vegetable juices, pickled vegetables, pickled vegetables, salted vegetables, pickled vegetables, radishes, pickles, pickles, wild vegetables, jams, jellies, bean products, etc., as well as the blanching or cooking processes of fruits and vegetables.

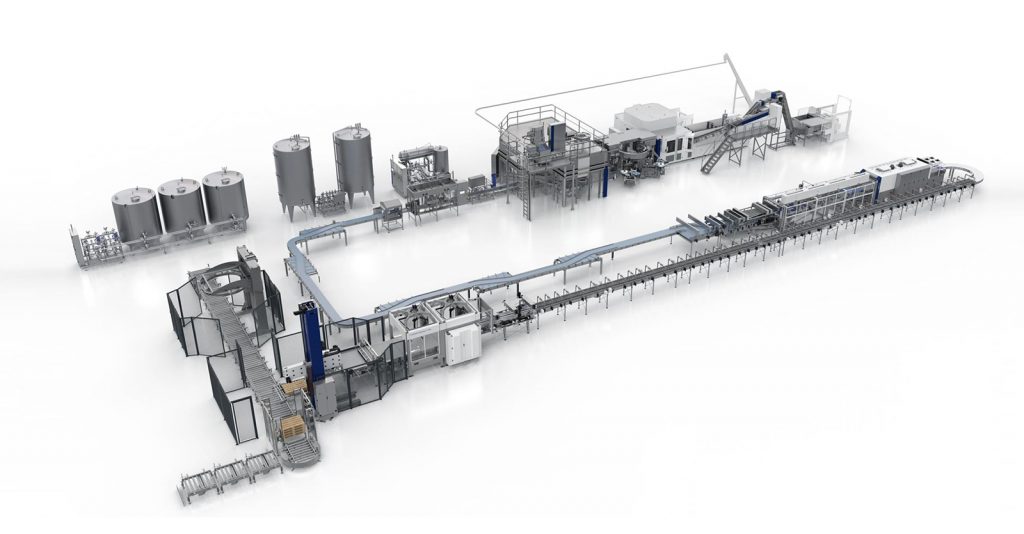

- Process Flow of Pasteurization Production Line

Sterilization - Cooling - Cleaning - Drying, equipped with a sterilization curve recorder to monitor the production process, to achieve the purpose of automatic, safe, and hygienic production. The conveyor, sterilizer, cooler, and air (drying) machine operate continuously throughout the process with automatic control.

- Key Points of Operation of the Pasteurization Production Line

- Firstly, open the cooling water pump of the pasteurization production line to ensure sufficient cooling water supply.

- Check the cooling water tank to confirm that there is water in the tank. Check whether the vacuum gauge is at zero and whether the interfaces of the four-section sterilizer are properly connected, and whether there is any looseness or air leakage at the interfaces. After checking, proceed to the next step.

- Do not start the pump empty, preheat the pasteurization production line with water until the heating temperature rises between the flash evaporators, then feeding can be started.

- At the same time, open the feeding pump and flash evaporator discharge pump to keep the liquid level in the flash evaporator below the centerline of the sight glass. After the liquid level is stable, proceed to the next step.

- Open the cooling water circulation system to keep the liquid level of the cooling water circulating in the cooling water mirror.

- Before starting the vacuum pump, close the valve of the pasteurization production line vacuum pump and then gradually open it to increase the vacuum pump.

- Precautions for Use of the Pasteurization Production Line

- After the operation of the pasteurization production line is completed, the equipment should be cleaned.

- When moving or rewiring the pasteurization production line, confirm the direction of the motor. If it is reversed, reverse any two phases of the three-phase power supply.

- Non-professionals are prohibited from opening the electrical system.

- Check the oil level and quality of the reducer every month, and add or replace the oil as necessary. The oil used is No. 32 engine oil.

TAG: Tunnel Pasteurizer UHT Sterilizer

-

![Advancing Food Safety with the Tunnel Pasteurizer Machine]() Advancing Food Safety with the Tunnel Pasteurizer MachineSep , 01 /2023

Advancing Food Safety with the Tunnel Pasteurizer MachineSep , 01 /2023 -

![HZM Machinery Provides Professional Tunnel Pasteurizer Machine Purchase and Installation]() HZM Machinery Provides Professional Tunnel Pasteurizer Machine Purchase and InstallationSep , 03 /2023

HZM Machinery Provides Professional Tunnel Pasteurizer Machine Purchase and InstallationSep , 03 /2023 -

![HZM Tunnel Pasteurizer Machine: The Ultimate Solution for Quality and Sustainability in Beverage Processing]() HZM Tunnel Pasteurizer Machine: The Ultimate Solution for Quality and Sustainability in Beverage ProcessingSep , 05 /2023

HZM Tunnel Pasteurizer Machine: The Ultimate Solution for Quality and Sustainability in Beverage ProcessingSep , 05 /2023 -

![Modern Beverage Tunnel Pasteurizer Machine]() Modern Beverage Tunnel Pasteurizer MachineSep , 06 /2023

Modern Beverage Tunnel Pasteurizer MachineSep , 06 /2023 -

![Key Points for Purchasing Fully Automatic Sterilization Pots]() Key Points for Purchasing Fully Automatic Sterilization PotsFeb , 20 /2024

Key Points for Purchasing Fully Automatic Sterilization PotsFeb , 20 /2024 -

![What equipment is needed to produce beverages?]() What equipment is needed to produce beverages?Mar , 28 /2024

What equipment is needed to produce beverages?Mar , 28 /2024

Home /

Home /