Common Failures and Solutions of Plastic Blow Molding Machine

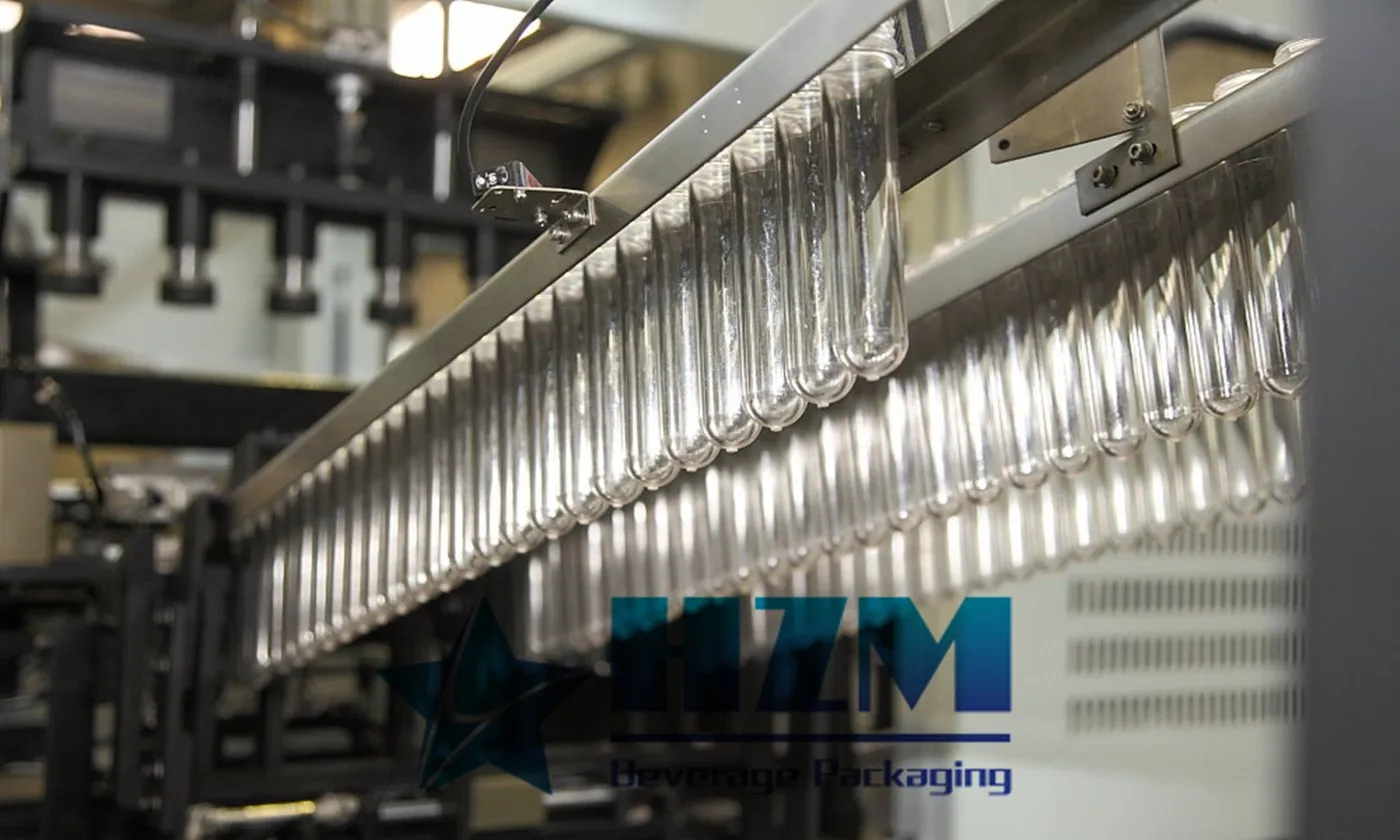

Plastic bottles are almost ubiquitous in our daily lives – water, beverages, tea, milk, oil, and other liquid products are all packaged in plastic bottles. As the machine responsible for producing plastic bottles, the plastic blow molding machine is widely used in various industries, contributing significantly to the development of the liquid packaging industry. However, being a complex machine that integrates mechanics, electronic control, and hydraulics, the plastic blow molding machine can inevitably experience failures if operated incorrectly, and poorly designed machines are more prone to problems. In this article, we will analyze and provide solutions to five common failures of plastic blow molding machines to help you overcome the challenges.

Five Common Failures and Solutions of Plastic Blow Molding Machine:

Excessive Noise

During the operation of the plastic blow molding machine, some irregular vibrations of the machine body can lead to significant noise. Additionally, certain guide wheels rolling on the cam's outer track and groove may produce substantial noise due to impact. Excessive noise not only creates an unfavorable working environment on-site but also affects the normal work and rest of nearby residents.

Solution: At the source, upgrading the old version of plastic blow molding machines to the new generation equipped with multi-axis servo motor control is possible. To mitigate sound propagation, increasing the workshop's sealing and providing operators with earplugs can be effective.

Accumulation of Material at the Bottom of Bottles

If there is material accumulation at the bottom of bottles produced by the plastic blow molding machine, the common reasons might be that the blowing time is too long, the air pressure is unstable, or the stretching rod is not adjusted properly.

Solution: Shorten the blowing time, reduce the descent speed of the stretching rod, increase the heating temperature at the bottom of the preform, and shorten the supply air pipeline.

Deformation of Bottle Mouth

Deformation of the bottle mouth in PET bottles is generally caused by continuous temperature rise in the heating machine, leading to mouth expansion.

Solution: Enhance the cooling at the bottle mouth through air cooling or water cooling, or install central air conditioning in the production workshop to lower the ambient temperature.

Difficulty in Mold Ejection

This situation may arise due to too short exhaust time of the plastic blow molding machine, malfunction of the exhaust valve, fracture of the locking screw, or excessive locking force.

Solution: Adjust the exhaust time, repair the exhaust valve and locking screw, or reduce the locking force.

Obvious Mold Joint Line on Bottles

If the mold joint line is too obvious, it might be due to insufficient mold clamping pressure, premature sealing time, or mold issues.

Solution: Increase the mold clamping pressure of the plastic blow molding machine, adjust the angle of the support bar during clamping, check for tight mold fit, and repair the mold thread matching position.

The Simplest Solution: Choose HZM Machinery's PET Fully Automatic Blow Molding Machine

The ever-changing market demands have prompted the need for updates and upgrades in blow molding machines. After intensive research and technological development, HZM Machinery has launched the sixth generation of fully automatic rotary blow molding machines, significantly reducing the occurrence of failures. The upgraded advantages include:

- A fast mold replacement mechanism with coordinated motion between the bottom mold and the open-close mold, controlled by locking blocks to reduce machine vibrations. Along with high-performance servo motors, mechanical arm positioning mechanisms, and an optimized exhaust channel design, the noise of the plastic blow molding machine is minimized.

- Precise servo stretching control, achieving maximum processing angles and flexibility.

- An optimized heating machine with cooling at the bottle mouth, combined with a precise temperature control system to prevent mouth deformation.

- Six-valve blow molding process with large-diameter blow molding valves for accurate control of high-pressure air pressure.

Furthermore, HZM Machinery provides blow molding mold design services, designing molds that meet the most stringent conditions from a professional perspective. Moreover, HZM offers excellent after-sales service, responding promptly to your specific needs, ensuring a convenient, professional, and responsive service attitude. Throughout the lifecycle of the PET fully automatic blow molding machine, HZM will be there with you!

TAG: Automatic Blow Molding Machine Blow Molding Machine

-

![Successful Delivery of New Blow Molding Machine to Indonesian Customer]() Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023

Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023 -

![The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and Precision]() The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023

The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023 -

![Automatic Rotary Blow Molding Machine: Features, Applications, and Maintenance]() Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023

Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023 -

![Maintenance and Care of 5 Gallon Bottle Blow Molding Machine]() Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023

Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023 -

![Solutions for Blow Molding Plastic Bottles]() Solutions for Blow Molding Plastic BottlesJun , 09 /2023

Solutions for Blow Molding Plastic BottlesJun , 09 /2023 -

![Automatic Blow Molding Machines: Unveiling the Secrets of Bottle Formation]() Automatic Blow Molding Machines: Unveiling the Secrets of Bottle FormationJun , 29 /2023

Automatic Blow Molding Machines: Unveiling the Secrets of Bottle FormationJun , 29 /2023 -

![Selling Automatic Blow Molding Machine – HZM Machinery]() Selling Automatic Blow Molding Machine – HZM MachineryJul , 10 /2023

Selling Automatic Blow Molding Machine – HZM MachineryJul , 10 /2023 -

![User What are the three types of blow moulding?]() User What are the three types of blow moulding?Nov , 23 /2023

User What are the three types of blow moulding?Nov , 23 /2023

Home /

Home /