Cold Drink Bottle Packing Machine Manufacturer ,Price

What is Cold Drink Bottle Packing Machine

A cold drink bottle packing machine is a specialized piece of equipment used in the beverage industry to package cold beverages such as soft drinks, juices, and water into bottles. These machines are designed to handle the entire process, including bottle rinsing, filling, capping, and labeling, ensuring that the cold drinks are securely packed and ready for distribution. Here's a breakdown of its features and functions:

Key Functions:

- Bottle Rinsing: The machine first rinses empty bottles to ensure they are clean and free from any contaminants before filling.

- Filling: Cold drink bottle packing machines often feature gravity or pressure filling mechanisms. They are optimized for cold liquid products to prevent foaming and ensure accurate filling levels.

- Capping: After filling, the machine automatically caps the bottles with plastic or metal caps to seal them.

- Labeling: Some machines come with integrated labeling systems that apply product labels on the bottles.

- Quality Control: Advanced machines also have sensors or inspection systems to ensure that the bottles are properly filled and sealed, removing any defective products from the production line.

Key Features:

- Low-temperature Operation: These machines are designed to work efficiently in low-temperature environments, ensuring that the cold drinks are filled without affecting product quality.

- High-speed Production: Most cold drink packing machines can handle large volumes, filling hundreds to thousands of bottles per hour.

- Customization: Machines can be customized for different bottle sizes and shapes, depending on the needs of the manufacturer.

- Sanitation: The machines are typically made of food-grade stainless steel, which is easy to clean and meets strict hygiene standards.

Types of Cold Drink Bottle Packing Machines:

- Automatic Cold Drink Packing Machines: Fully automated systems that handle rinsing, filling, capping, and labeling with minimal manual intervention.

- Semi-Automatic Machines: These machines require some manual input but still streamline much of the process, such as filling and capping.

- Monoblock Machines: These combine rinsing, filling, and capping into one compact unit, ideal for small to medium production lines.

Industries and Applications:

Cold drink bottle packing machines are widely used in:

- Soft drink manufacturing

- Bottled water production

- Juice bottling companies

- Beverage co-packers

These machines help maintain product integrity, maximize efficiency, and reduce labor costs, making them essential in large-scale beverage production.

cold drink bottle packing machine price

The price of a cold drink bottle packing machine can vary significantly depending on several factors such as the level of automation, production capacity, the brand, and any additional features (like labeling, capping, or sterilization functions). Below is a general range of prices based on machine type and specifications:

Price Range:

- Semi-Automatic Cold Drink Bottle Packing Machines

- Price Range: $5,000 to $20,000 USD

- These machines require some manual operation but can handle a decent level of production for smaller manufacturers. They usually have lower speeds and are ideal for startups or small-scale operations.

- Fully Automatic Cold Drink Bottle Packing Machines

- Price Range: $20,000 to $100,000+ USD

- These machines are more advanced, handling everything from bottle rinsing to capping and labeling without manual intervention. The price depends on the production speed (bottles per hour), bottle size flexibility, and other features.

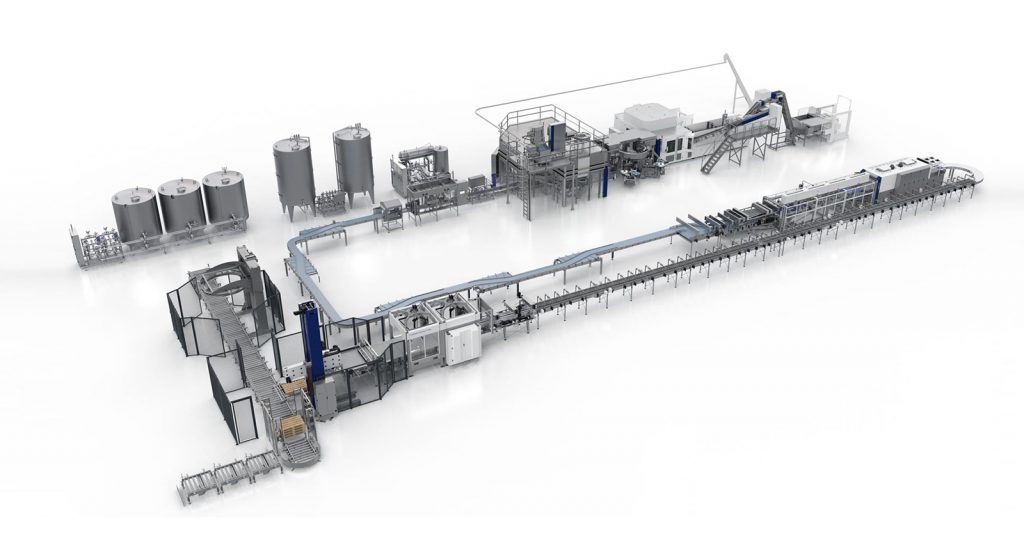

- High-Speed Fully Automatic Bottling Lines (Monoblock or Triblock Systems)

- Price Range: $100,000 to $500,000+ USD

- These machines are designed for large-scale production, handling thousands of bottles per hour. They combine multiple functions like rinsing, filling, capping, and labeling in one system, optimized for efficiency in high-demand environments such as soft drink and bottled water plants.

- Customized Cold Drink Bottling Systems

- Price Range: $150,000 to $1 million+ USD

- Large beverage companies may opt for fully customized bottling lines, which include advanced automation, quality control systems, and tailored configurations for specific bottle sizes and beverage types. These systems are typically integrated into a larger production and packaging process.

Additional Factors Influencing Price:

- Production Speed: Machines that can process more bottles per minute (BPM) or hour will typically be more expensive.

- Bottle Size Flexibility: Machines that can handle a wide range of bottle sizes (e.g., 250 ml to 2 liters) usually cost more due to their versatility.

- Sterilization and Sanitation Features: Machines with integrated cleaning or sterilization systems (such as UV sterilizers) for the bottles and filling lines often come at a higher price.

- Brand and Country of Origin: Machines from well-known manufacturers can also differ in price depending on the reputation and quality of the machine.

HZM Machinery – Professional Cold Drink Bottle Packing Machine Manufacturer

HZM Machinery is a leading manufacturer of high-efficiency, reliable cold drink bottle packing machines, dedicated to providing advanced packaging solutions for beverage production companies worldwide. Whether it's carbonated drinks, juices, mineral water, or other cold beverages, our machines are designed with precision and superior performance to meet your production needs, helping you enhance efficiency and ensure product quality.

Our Advantages

- Fully Automated Packaging Solutions

HZM Machinery offers fully automated cold drink bottling machines that handle everything from bottle rinsing, filling, to capping. Our equipment is designed to operate efficiently in low-temperature environments, minimizing foam formation and ensuring the quality of the beverages. - Multi-Function Integration

Our machines integrate various functions such as washing, filling, capping, and labeling, making them capable of handling bottles of different sizes and shapes. This enhances the flexibility and efficiency of the production line. The modular design allows the equipment to be tailored to suit any production scale, from small to large beverage operations. - High Capacity and Precision

HZM Machinery’s cold drink bottling machines are designed for high-capacity operations, filling thousands of bottles per hour to ensure fast and efficient production. Our machines employ advanced filling technology to ensure accurate filling and sealing, reducing waste and increasing production efficiency. - Hygienic Design

To meet strict food-grade hygiene standards, our machines are made of high-quality stainless steel, making them easy to clean and resistant to corrosion. The built-in automatic cleaning and sterilization system ensures that the machine is thoroughly cleaned before every filling session, preventing product contamination. - Customized Solutions

No matter the size or shape of your bottles, HZM Machinery can provide a custom-designed filling system to meet your specific needs. Our engineering team, with years of industry experience, can design and deliver the most suitable solutions for your production requirements.

Contact Us

For more information about HZM Machinery's cold drink bottle packing machines or to receive customized solutions, please contact our sales team today. HZM Machinery is your trusted partner in the beverage packaging industry, helping you boost production efficiency and drive business growth.

TAG: Beverage Packaging Machine Bottle Packing Machine cold drink packing machine

-

![How to Properly Maintain and Service Automatic Beverage Packaging Machines]() How to Properly Maintain and Service Automatic Beverage Packaging MachinesMay , 17 /2023

How to Properly Maintain and Service Automatic Beverage Packaging MachinesMay , 17 /2023 -

![Professional Beverage Packaging Machine Manufacturer]() Professional Beverage Packaging Machine ManufacturerJun , 06 /2023

Professional Beverage Packaging Machine ManufacturerJun , 06 /2023 -

![Automatic Linear Mineral Water Touchscreen Filling And Packaging Machine Sus304]() Automatic Linear Mineral Water Touchscreen Filling And Packaging Machine Sus304Jun , 09 /2023

Automatic Linear Mineral Water Touchscreen Filling And Packaging Machine Sus304Jun , 09 /2023 -

![Stainless Steel 380v Mineral Water Bottle Packing Machine]() Stainless Steel 380v Mineral Water Bottle Packing MachineJun , 09 /2023

Stainless Steel 380v Mineral Water Bottle Packing MachineJun , 09 /2023 -

![Easy Operate Electric 500ml Glass Bottle Packing Machine]() Easy Operate Electric 500ml Glass Bottle Packing MachineJun , 09 /2023

Easy Operate Electric 500ml Glass Bottle Packing MachineJun , 09 /2023 -

![High Efficiency SS304 Bottle Packing Machine For Beverage]() High Efficiency SS304 Bottle Packing Machine For BeverageJun , 09 /2023

High Efficiency SS304 Bottle Packing Machine For BeverageJun , 09 /2023 -

![Beverage Aseptic Filling Machine: The Perfect Combination of Freshness and Safety]() Beverage Aseptic Filling Machine: The Perfect Combination of Freshness and SafetyAug , 13 /2023

Beverage Aseptic Filling Machine: The Perfect Combination of Freshness and SafetyAug , 13 /2023 -

![What is a Beverage Packaging Machine?]() What is a Beverage Packaging Machine?Aug , 25 /2023

What is a Beverage Packaging Machine?Aug , 25 /2023

Home /

Home /