Coca-Cola Filling Machine: An Efficient Production Tool for Carbonated Beverages

Coca-Cola, as one of the world's most popular carbonated beverages, consumes a significant amount of production processes and resources annually. To meet market demand, manufacturers rely on efficient production lines and innovative technology. Among these, the Coca-Cola filling machine is undoubtedly an essential invention in the carbonated beverage industry, providing a highly automated and efficient solution for filling carbonated drinks.

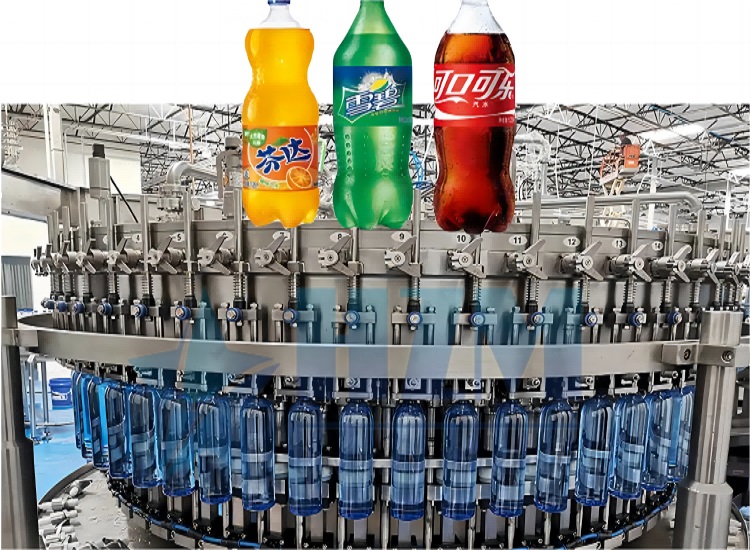

The working principle of the Coca-Cola filling machine involves mixing the prepared Coca-Cola liquid with carbon dioxide gas and then filling it into bottles or cans, followed by sealing and labeling. Here is some key information about Coca-Cola filling machines:

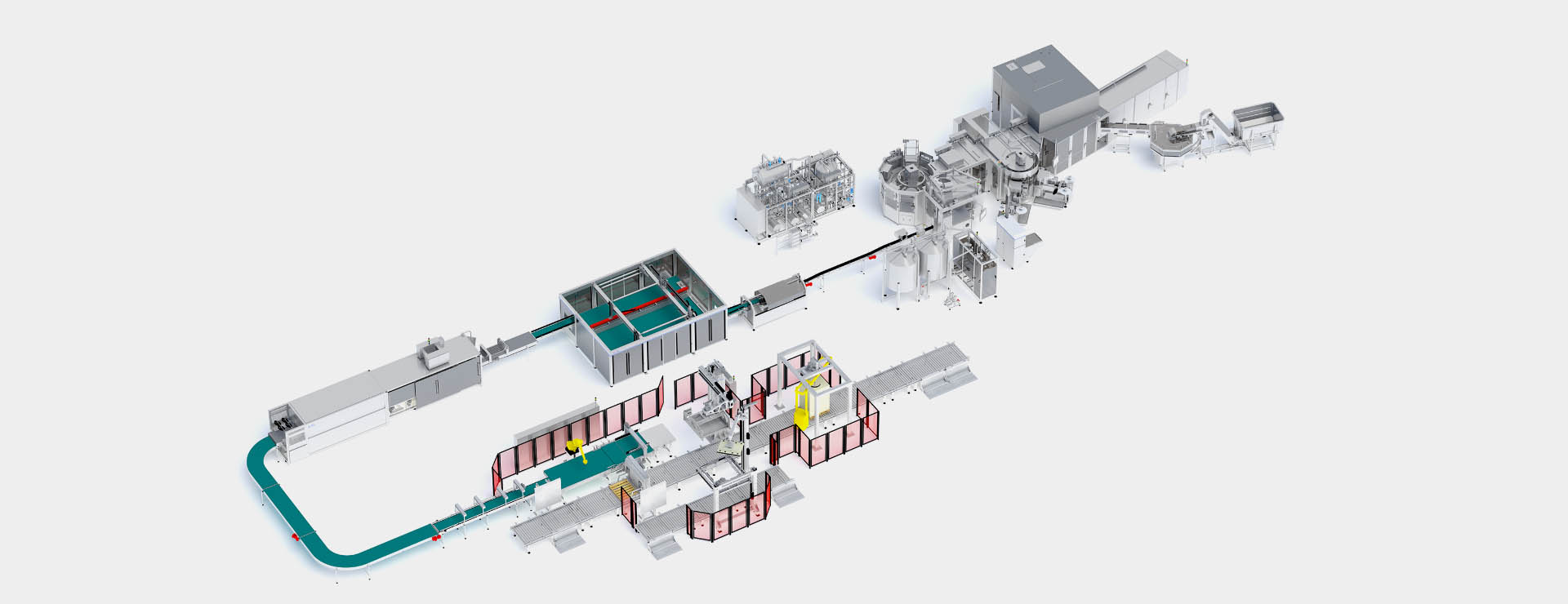

- Automated Process: Coca-Cola filling machines are highly automated devices. They can perform various production steps automatically, from bottle supply and cleaning to liquid filling, sealing, and label attachment. This automation greatly enhances production efficiency, reduces the need for manual labor, and lowers production costs.

- Precise Filling Control: The taste and quality of Coca-Cola are crucial to consumers. Coca-Cola filling machines employ precise flow control and measurement techniques to ensure that each bottle of Coca-Cola has a consistent taste and flavor. This precision is vital for maintaining brand reputation.

- High-Speed Production Capacity: Coca-Cola filling machines can operate at extremely high speeds, filling thousands of bottles of Coca-Cola per hour. This is crucial for meeting large-scale market demands, especially during hot summers and various holiday seasons.

- Hygiene and Safety: Carbonated beverage production requires strict hygiene control to prevent the growth of bacteria and other contaminants. Coca-Cola filling machines are well-designed, easy to clean, and maintain to ensure product hygiene and safety.

- Environmental Considerations: With increasing environmental concerns, Coca-Cola manufacturers are also working to reduce carbon emissions and waste. Some modern Coca-Cola filling machines incorporate energy-saving technology and recyclable materials to minimize their environmental impact.

- Customization Capability: Coca-Cola bottles come in various sizes and shapes for different brands, so Coca-Cola filling machines typically offer flexible configuration options to accommodate different bottle or can specifications. This customization capability allows manufacturers to adapt to market demands flexibly.

In summary, Coca-Cola filling machines are an indispensable part of the carbonated beverage industry. They not only enhance production efficiency but also ensure product quality and hygiene standards. As technology continues to advance, Coca-Cola filling machines will continue to play a crucial role in carbonated beverage production, providing consumers with high-quality Coca-Cola products. Additionally, they are contributing to the industry's sustainability and environmental efforts, supporting the sustainable development of the industry.

TAG: Carbonated Drinks Filling Machine Coca-Cola Filling Machine

-

![Carbon Dioxide Mixer Machine in Carbonated Beverage Production Equipment: Significance and Process]() Carbon Dioxide Mixer Machine in Carbonated Beverage Production Equipment: Significance and ProcessAug , 09 /2023

Carbon Dioxide Mixer Machine in Carbonated Beverage Production Equipment: Significance and ProcessAug , 09 /2023 -

![Carbonated Beverage manufacturing process flow]() Carbonated Beverage manufacturing process flowSep , 14 /2023

Carbonated Beverage manufacturing process flowSep , 14 /2023 -

![Beer Bottling Machines for Sale by HZM Machinery]() Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023

Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023 -

![Automated Production Line for Carbonated Beverages: 36,000 Bottles Per Hour]() Automated Production Line for Carbonated Beverages: 36,000 Bottles Per HourOct , 30 /2023

Automated Production Line for Carbonated Beverages: 36,000 Bottles Per HourOct , 30 /2023

Home /

Home /