Capping, Sterilization, and Labeling in Beer Bottling Systems

Capping

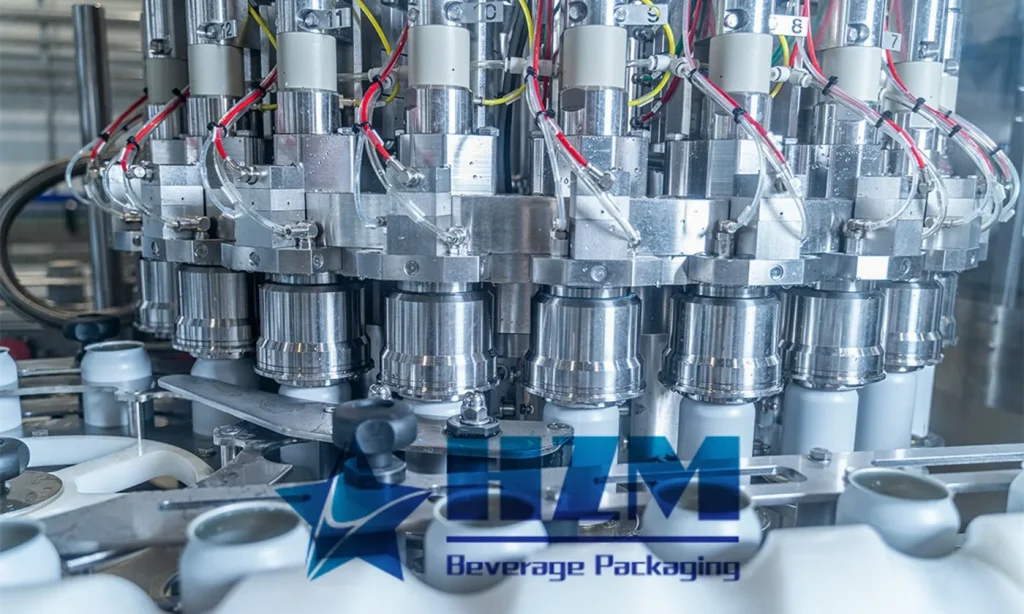

Filled beer bottles should be capped promptly, ensuring there is no air in the bottle neck during capping. Glass bottles used for beer are typically sealed with crown caps, which have 21 serrations that seal the bottle when pressed together during capping. A PVC plastic film inside the cap serves as a sealing liner. The capping machine and filling machine are installed together and driven by the same drive unit to ensure synchronized operation. The capping machine is also a rotary machine and operates much faster than the filling machine.

(1) Process Requirements:

- The size of the bottle cap must match the beer bottle, and there should be no burrs around the cap. The cap should undergo dust removal with sterile air.

- The horizontal level at the bottom of the cap-falling groove should be 0.5mm higher than the entrance to the capping head to facilitate cap insertion.

- The spring pressure should be adjusted uniformly based on the properties of the cap.

- After capping, the cap should be tightly and properly sealed without any unilateral protrusion. The capped cap should not pass through a circular hole of φ28.6mm but should pass through a φ29.1mm hole. Over-tightening can lead to bottle neck breakage, while being too loose can result in air leakage during sterilization.

(2) Capping Operation

- Measure the travel between each capping element and control the interval to achieve the best capping effect.

- Adjust the capping mold stroke and spring pressure based on the cap's properties. Thicker crown caps or bottle liners require higher pressure.

- Control the outer diameter of the capped cap to be between φ28.6 and 29.1mm. A pressure sealing tester for caps can be used to measure the cap's pressure resistance. A dual-needle pressure gauge can automatically display and record the cap's maximum instantaneous pressure (0.85MPa).

Sterilization

To ensure a longer shelf life for beer, the pasteurization method is often used for sterilization to maintain high biological stability.

(1) Heat Sterilization Methods:

- Heat sterilization can be divided into pre-bottling sterilization and post-bottling sterilization. Pre-bottling sterilization, also known as flash sterilization, is often done using a plate heat exchanger. Post-bottling sterilization is the method adopted by the majority of beer production companies worldwide, and it typically uses tunnel pasteurizers or continuous pasteurization machines.

In 1860, French scientist Louis Pasteur demonstrated that the application of low-temperature sterilization (heating to 60°C and maintaining for a certain time) could kill microbial cells. This method became known as the Pasteurization method. The sterilization effect caused by heating to 60°C for 1 minute is defined as one Pasteurization unit (Pu) and is represented by Pu=T×1.393(t-60), where T is time (minutes) and t is temperature (°C). Experimental Pu values for effective sterilization of beer are typically in the range of 5–6 in the laboratory and controlled at 15–30Pu in production. Pu values at different sterilization temperatures for handling 1 minute are listed in Table 5-2-3.

Recently, instantaneous pasteurization methods such as flash pasteurization and ultra-high-temperature pasteurization (UHT, sterilization temperature between 115°C and 137°C) have been used to extend the shelf life of canned beer.

(2) Sterilization Operation:

- Post-bottling beer sterilization involves the beer to be sterilized entering the sterilization machine from one end. As it moves, the temperature inside the bottles gradually rises, reaching around 62°C (the highest sterilization temperature). It is held at this temperature for a certain period, after which the temperature inside the bottles gradually drops to near room temperature as they exit the sterilization machine and enter the adjacent labeling machine. The entire sterilization process takes about 1 hour. Pre-bottling beer sterilization involves pumping cold beer into the preheating zone for initial heating. Then, it enters the heating zone (up to 71–79°C) for a specific time and subsequently enters the cooling zone, where it is subjected to heat exchange with cold beer from the heat exchanger. This process lowers the temperature to the required level for bottling.

(3) Key Process Conditions:

- Sterilization temperature (inside the bottle) for post-bottling beer: 15°C → 30°C → 45°C → 62°C → 54°C → 45°C → 35°C. Spraying water pressure: 0.2–0.3MPa.

- During heating, the temperature difference between the water and beer should not exceed 30°C, and during cooling, it should not go below 22°C to reduce bottle and beer loss. It is advisable to add appropriate adsorbents, chelating agents, and alkali to the spraying water to maintain a weak alkaline environment. Sterilization process conditions for pre-bottling beer are similar to the described operation, usually controlled at 72–73°C, maintained for 30 seconds, or at 68–72°C, held for 50 seconds. The entire process takes about 2 minutes and has almost no impact on beer quality.

(4) Sterilization Process Requirements:

- Sterilized beer should not have yeast turbidity, and the appearance, flavor, and aroma of the finished beer should not significantly differ from the original beer. There should be no noticeable particles or black rings in the bottle neck.

- The volume of the bottle neck portion of bottled beer should be 3% of the total volume when sterilized at temperatures below 65°C and with a CO2 mass fraction of 0.4%–0.5%. When sterilized at temperatures above 65°C, it should be 4% of the total volume to prevent bottle breakage due to high pressure during sterilization.

- The distribution of spraying water should be uniform. The main sterilization zone should have a temperature of 61–62°C, with a sterilization effect of 15–30Pu.

(5) Operating Key Points:

- Strictly control temperatures and times in each zone. The temperature difference between zones should not exceed 35°C. The rate of temperature increase (decrease) for bottles should be controlled at 2–3°C/min to prevent bottle breakage.

- Monitor temperatures in each zone regularly and maintain temperature variations within ±1°C. Pu values should be measured 1–2 times per shift.

- Clean the machine body and nozzles at the end of each day's work to keep the nozzles clear. Maintain a spraying water pressure of 0.2–0.3MPa.

- To prevent equipment corrosion due to acidic spraying water resulting from beer bottle breakage, adjust the pH of the spraying water to a neutral level (pH 7.6–8) using 1%–2% NaOH. If necessary, add 5–10mg/L trisodium phosphate to prevent nozzle blockage and the formation of salt deposits when bottles dry.

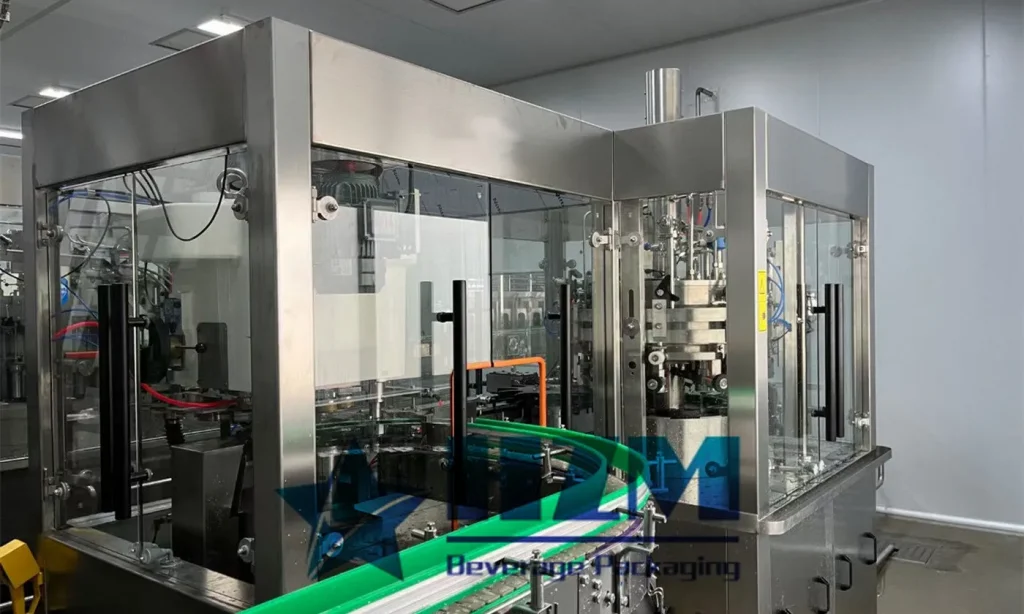

Labeling

The label of beer directly affects its appearance quality. Process requirements demand that the label used must be consistent with the product, and the production date must be clearly indicated. The label should be neat, well-aligned, not peeling off, and free of defects. The adhesive should be pH neutral, have good initial adhesion, appropriate instantaneous viscosity, and should not fall off during beer storage or become moldy or deteriorate when exposed to moisture. Labeling machines include straight-line vacuum drum labeling machines and rotary labeling machines. After labeling, the bottles can be packaged manually or mechanically (e.g., shrink-wrapped, placed in plastic or cardboard boxes) for sale.

The labeling process includes gluing, label pickup, label clamping, label application, label smoothing, and bottle positioning, bottle entry, bottle pressing, label advance, label pressing, and bottle exit.

TAG: Beer Filling Machine Glass Bottle Filling Machine

-

![Glass Bottle Packaging Equipment]() Glass Bottle Packaging EquipmentJun , 07 /2023

Glass Bottle Packaging EquipmentJun , 07 /2023 -

![Coffee Tea Granule Glass Bottle Filling Machine]() Coffee Tea Granule Glass Bottle Filling MachineJun , 09 /2023

Coffee Tea Granule Glass Bottle Filling MachineJun , 09 /2023 -

![Full Automatic All In One 8000 Bph Glass Bottle Filling Machine]() Full Automatic All In One 8000 Bph Glass Bottle Filling MachineJun , 09 /2023

Full Automatic All In One 8000 Bph Glass Bottle Filling MachineJun , 09 /2023 -

![Magnetic Pump 500ml SS304 Glass Bottle Soda Filling Machine]() Magnetic Pump 500ml SS304 Glass Bottle Soda Filling MachineJun , 09 /2023

Magnetic Pump 500ml SS304 Glass Bottle Soda Filling MachineJun , 09 /2023 -

![Beer Bottling Machines for Sale by HZM Machinery]() Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023

Beer Bottling Machines for Sale by HZM MachinerySep , 19 /2023 -

![small scale beer bottling equipment]() small scale beer bottling equipmentSep , 20 /2023

small scale beer bottling equipmentSep , 20 /2023 -

![Beer Filling Machine Principle]() Beer Filling Machine PrincipleOct , 03 /2023

Beer Filling Machine PrincipleOct , 03 /2023 -

![Basic Principles of Beer Packaging]() Basic Principles of Beer PackagingOct , 05 /2023

Basic Principles of Beer PackagingOct , 05 /2023

Home /

Home /