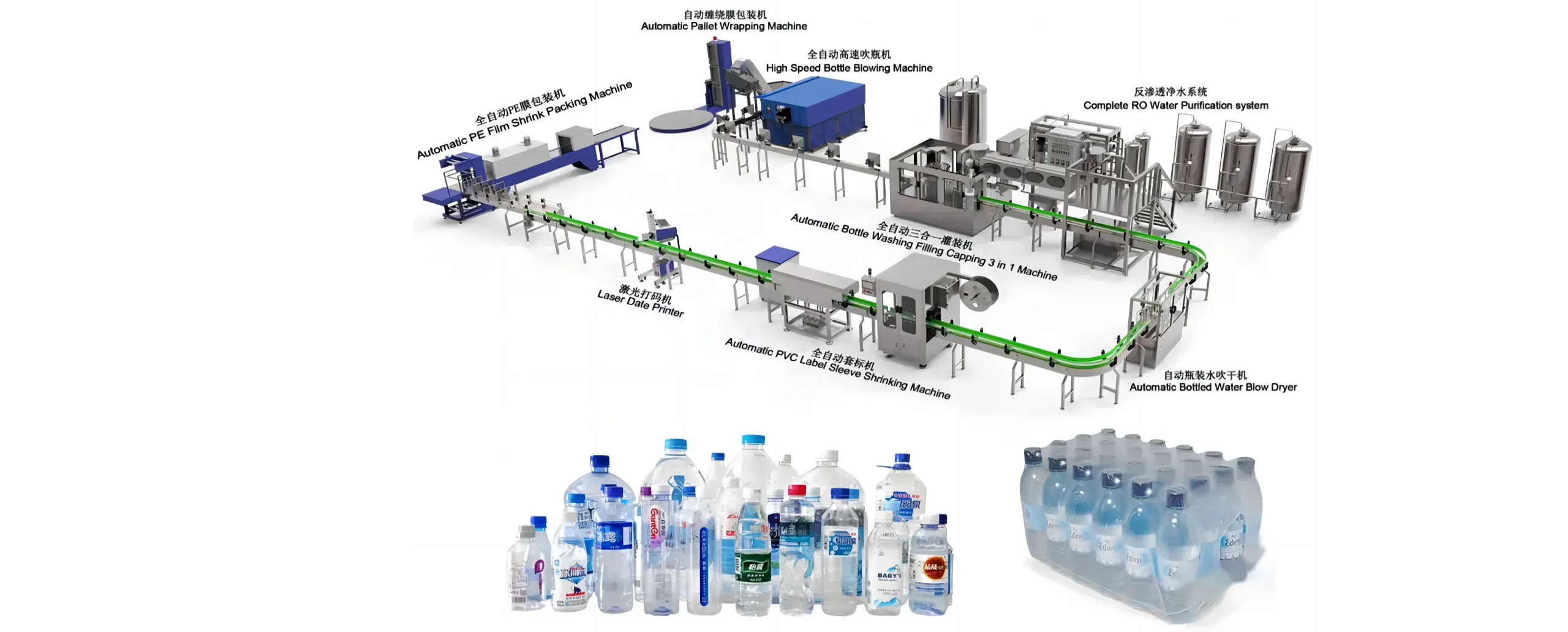

Bottled Water Production Line Equipment Prices And Parameters

When choosing bottled water production line equipment, it is important to consider your specific needs and budget. It is also important to do your research and compare prices from different suppliers.

HZM Machinery Manufacturer is a comprehensive professional Chinese supplier of bottled water production line equipment integrating R&D, manufacturing, and sales. We can provide turnkey projects and have professional after-sales service engineers. Currently, our equipment is exported to more than 30 regions and countries in domestic and foreign markets.

Bottled Water Production Line Equipment Prices and Parameters

Our water treatment systems utilize advanced purification methods such as reverse osmosis and UV sterilization to ensure the highest quality of water for bottling. With capacities ranging from small-scale operations to large-scale production facilities, our systems are customizable to meet specific requirements.

| Attribute | Details |

|---|---|

| Warranty of core components | 2 years |

| Core Components | Pressure vessel, Pump, PLC, touch screen |

| Place of Origin | Jiangsu, China |

| Warranty | 2 years |

| Productivity | 3000-100000 L/Hour |

| Weight (KG) | 4200 kg |

| Condition | New |

| Brand Name | HZM |

| Material | Wooden case |

| Weight | According to your order |

| Size | According to your order |

| Power | 3-35KW |

| Product name | Water Treatment System |

| Application | Water Filtration |

| Type | Automatic |

| Function | Make Pure Drinking Water |

| Keywords | RO Water Filtration |

| After-sales Service Provided | Engineers |

| Feature | Automatic Control |

| Processing | Pre-treatment System+ RO System |

Price: Factory direct sales price

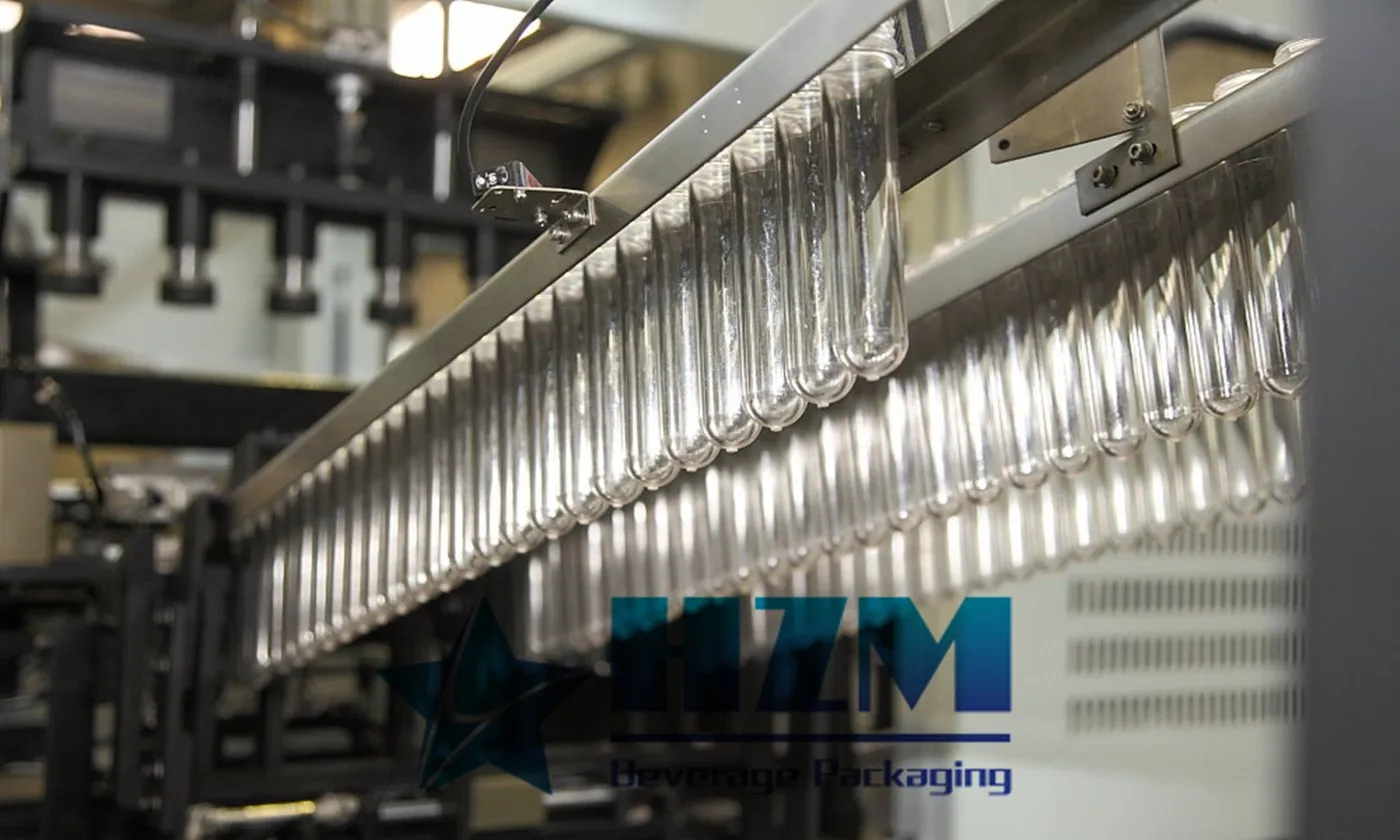

Blow Molding Machines

Our blow molding machines are engineered to efficiently create bottles of various sizes and shapes, maintaining strict quality standards. With options for different production capacities and automation levels, these machines offer versatility and reliability to meet the demands of various production scales.

| Model | HZ-CS6-38 | HZ-CS8-38 | HZ-CSS9-38 | HZ-CSS12-38 |

| Clamping force(KG) | 60,000 | 72,000 | 60,000 | 72,000 |

| Clamping stroke(mm) | 130 | 130 | 130 | 130 |

| Stretching stroke(mm) | 320 | 350 | 320 | 240 |

| Bottom stroke(mm) | 50 | 50 | 50 | 50 |

| Cavity pitch(mm) | 120 | 120 | 80 | 80 |

| Number of cavity | 6 | 8 | 9 | 12 |

| Max volume(L) | 2 | 2 | 2 | 0.7 |

| Neck diameter range (mm) | 30 | 30 | 18-30 | 18-30 |

| Max container diameter(mm) | 105 | 105 | 105 | 70 |

| Max container height (mm) | 320 | 320 | 320 | 240 |

| Carriage unit(pcs) | 120 | 162 | 156 | 192 |

| Total power(KW) | 50 | 78 | 49 | 67 |

| Air consuming (ltr/min) | 8,000 | 9,100 | 10,500 | 14,000 |

| Capacity for 0.5L (BPH) |

12,000 | 16,000 | 18,000 | 21,600 |

| Dimension(mm) | 5,530*1,750*2,600 | 6,600*1,900*2,600 | 6,100*1,800*2,600 | 7,000*2,020*2,600 |

| Weight(KG) | 8,000 | 10,000 | 8,000 | 12,000 |

Price: Factory direct sales price

Our bottle filling machines are designed to accurately fill bottles with purified water, ensuring precise measurements and consistent quality. With options for gravity or pressure-based filling methods and adjustable production speeds, our machines offer flexibility to accommodate different bottle sizes and throughput requirements.

| Model | XGF14-12-5 | XGF16-16-5 | XGF24-24-8 | XGF32-32-8 | XGF40-40-10 |

| Capacity (for 500ml) |

5,000BPH | 8,000BPH | 12,000BPH | 15,000BPH | 18,000BPH |

| Bottle diameter | 50~110mm | ||||

| Bottle height | 160~310mm | ||||

| Air source pressure | 0.7MPa | ||||

| Voltage | 380/415V | ||||

| Main motor power | 1.5KW | 2.2KW | 3.0KW | 4.0KW | 7.5KW |

| Dimension | 2360*1770*2700 | 2760*2060*2700 | 2800*2230*2700 | 3550*2650*2700 | 4360*3300*2700 |

Price: Factory direct sales price

Capping Machines

Our capping machines seamlessly apply caps to filled bottles, providing secure sealing to prevent contamination and ensure product integrity. Available in manual, semi-automatic, and fully automatic configurations, these machines offer efficiency and reliability for continuous production.

| Name | Tech. Data |

| Nominal capacity for 500ml (BPH) | 12000-48000 |

| Rate of finished product (%) | 99.5 |

| Mould cavities (N) | 6-24 |

| Filling heads(N) | 24-80 |

| Capping heads(N) | 8-22 |

| Max bottle diameter (mm) | 110 |

| Max bottle height(mm) | 340 |

| Max bottle mouth diameter (mm) | 38 |

| Max preform height (mm) | 135 |

| Max volume(ml) | 2000 |

| Medium power absorbed (%) | 60 |

| Voltage permitted (%) | +/-5% |

| Frequency permitted (%) | +/-1% |

| Voltage auxiliary (VDC) | 24 |

Price: Factory direct sales price

Labeling Machines

Our labeling machines precisely apply labels to bottles, enhancing branding and product identification. With options for wrap-around, front-and-back, and sleeve labeling, our machines offer versatility to meet diverse labeling needs while ensuring accurate placement and adherence.

| Model | Capacity

(BPH) |

Labeling accuracy

(mm) |

Bottle Diameter

(mm) |

Label Height

(mm) |

Label thickness

(mm) |

Dimension

(mm) |

| SHB-150 | 9000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-250 | 15000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-350 | 21000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-400 | 24000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

| SHB-450 | 27000 | ±1 | φ28-φ125 | 30-250 | 0.035-0.13 | 2100*850*2000 |

Price: Factory direct sales price

Packaging Machines

Our packaging machines streamline the packaging process, efficiently assembling filled and labeled bottles into cases or shrink-wrapped packs. With customizable configurations and adjustable production speeds, our machines optimize efficiency while maintaining product integrity during packaging.

| Model | Carton Dimension

(mm) |

Bottle Height

(mm) |

Bottle Diameter

(mm) |

Total Weight

(kg) |

Capacity

(ppm) |

Dimension

(mm) |

| CPM-20 | 550<L+W+H<1000 | 110-340 | Φ50-180 | 4500 | 20 | 8870*3000*1820 |

| CPM-35 | 550<L+W+H<1000 | 110-340 | Φ50-180 | 5000 | 35 | 8870*3000*1820 |

| CPM-45 | 550<L+W+H<1000 | 110-340 | Φ50-180 | 7000 | 45 | 12380*1960*1906 |

| CPM-60 | 550<L+W+H<1000 | 110-340 | Φ50-180 | 11000 | 60 | 12380*3820*2628 |

Price: Factory direct sales price

Factors affecting the price of bottled water production line equipment:

Production capacity

It refers to the number of bottled water that can be produced per hour. Common specifications are 1000 bottles/hour, 2000 bottles/hour, 5000 bottles/hour, and so on.

Automation level

It refers to the level of automation of the equipment operation. Fully automatic production lines are more efficient but also more expensive.

Bottle type and size

Different bottle specifications require matching filling equipment. For example, the equipment required for producing 500ml bottled water is different from that for producing 2L bottled water.

Contact us

Our equipment is exported to more than 30 regions and countries, catering to both domestic and international markets. With a focus on innovation, reliability, and customer satisfaction, HZM Manufacturer is your trusted partner for all your bottled water production needs. Contact us today to learn more about our equipment prices and specifications, and discover how we can help streamline your production operations.

TAG: Blow Molding Machine Bottled Water Production Line Water Filling Machine Water Treatment Systems

-

![PET Bottle Water Filling Machine]() PET Bottle Water Filling Machine

PET Bottle Water Filling Machine -

![3-10L Big PET Bottle Water Filling Machine]() 3-10L Big PET Bottle Water Filling Machine

3-10L Big PET Bottle Water Filling Machine -

![3-5 Gallon Water Filling Line]() 3-5 Gallon Water Filling Line

3-5 Gallon Water Filling Line -

![Automatic Water Bottle Filling Machine]() Automatic Water Bottle Filling Machine

Automatic Water Bottle Filling Machine -

![5 Gallon Bottle Blow Molding Machine]() 5 Gallon Bottle Blow Molding Machine

5 Gallon Bottle Blow Molding Machine -

![Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine]() Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine

Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine -

![Full Electric Servo Type Blow Molding Machine]() Full Electric Servo Type Blow Molding Machine

Full Electric Servo Type Blow Molding Machine -

![Automatic Blow Molding Machine]() Automatic Blow Molding Machine

Automatic Blow Molding Machine

-

![Successful Delivery of New Blow Molding Machine to Indonesian Customer]() Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023

Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023 -

![Unveiling the Precision and Efficiency of Water Filling Machines]() Unveiling the Precision and Efficiency of Water Filling MachinesMar , 24 /2023

Unveiling the Precision and Efficiency of Water Filling MachinesMar , 24 /2023 -

![Soft Drinks Sparkling Water Filling Machine: A Comprehensive Guide]() Soft Drinks Sparkling Water Filling Machine: A Comprehensive GuideApr , 26 /2023

Soft Drinks Sparkling Water Filling Machine: A Comprehensive GuideApr , 26 /2023 -

![The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and Precision]() The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023

The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023 -

![Automatic Rotary Blow Molding Machine: Features, Applications, and Maintenance]() Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023

Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023 -

![Leading Manufacturer of Mineral Water Filling Machines]() Leading Manufacturer of Mineral Water Filling MachinesMay , 27 /2023

Leading Manufacturer of Mineral Water Filling MachinesMay , 27 /2023 -

![Your Trusted Manufacturer of Mineral Water Filling Machines]() Your Trusted Manufacturer of Mineral Water Filling MachinesJun , 06 /2023

Your Trusted Manufacturer of Mineral Water Filling MachinesJun , 06 /2023 -

![Maintenance and Care of 5 Gallon Bottle Blow Molding Machine]() Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023

Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023 -

![Bottled Drinking Water Production Line: Equipment and Production Process]() Bottled Drinking Water Production Line: Equipment and Production ProcessDec , 07 /2023

Bottled Drinking Water Production Line: Equipment and Production ProcessDec , 07 /2023 -

![Bottled Water Production Line: Procurement, Installation, and Commissioning]() Bottled Water Production Line: Procurement, Installation, and CommissioningDec , 14 /2023

Bottled Water Production Line: Procurement, Installation, and CommissioningDec , 14 /2023 -

![How to Choose Bottled Water and Beverage Production Line Equipment]() How to Choose Bottled Water and Beverage Production Line EquipmentDec , 15 /2023

How to Choose Bottled Water and Beverage Production Line EquipmentDec , 15 /2023 -

![How to Establish a Bottled Water and Beverage Factory?]() How to Establish a Bottled Water and Beverage Factory?Dec , 16 /2023

How to Establish a Bottled Water and Beverage Factory?Dec , 16 /2023

Home /

Home /