Bottle water production line process analysis

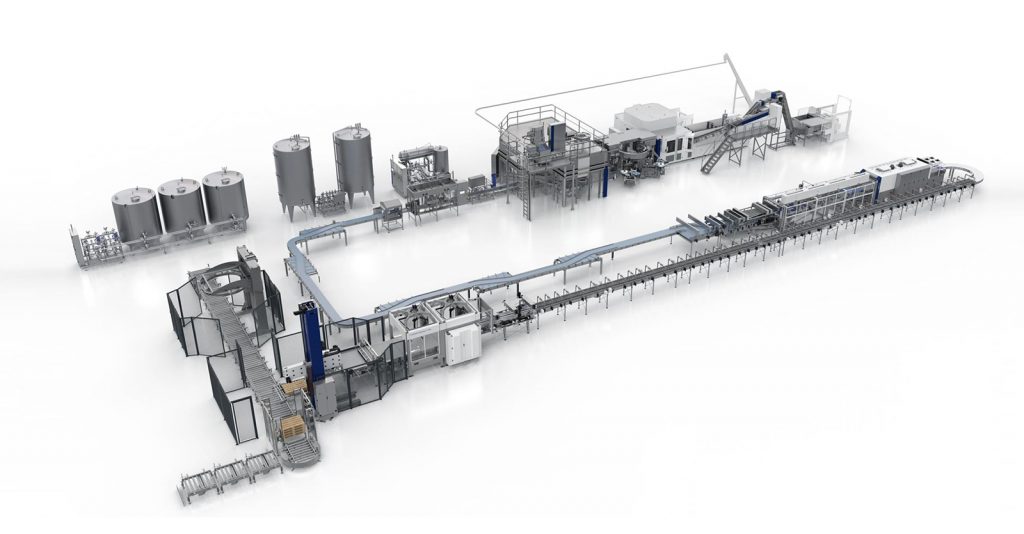

A bottle water production line is a set of equipment used to produce bottled water, such as pure water, mineral water. A fully automatic bottle water production line includes water treatment equipment, blowing equipment, bottle feeding track, bottle handling machine, bottle filling machine, bottle cap disinfection equipment, finished product conveyor, inspection equipment, inkjet printing equipment, label equipment, and packaging equipment. When the output is large, it can be equipped with a stacking machine to realize full automation.

Water treatment equipment

Water treatment equipment is an important part of the bottle water production line. It is used to remove impurities and pollutants from water to meet drinking standards. Water treatment equipment generally includes quartz sand filters, activated carbon filters, ion exchange resins, precision filters, membrane filtration equipment, ozone generators, and pure water tanks.

Blowing equipment

Blowing equipment is used to make bottles from bottle blanks. After the bottle blank enters the blowing machine, it is first evenly heated to a certain plasticity and then enters the blowing mold, where it is formed once under the action of high-pressure gas.

Bottle feeding method

According to the output of the production line, the corresponding bottle feeding method is selected to send the empty bottles into the wind power conveying guide rail. For a production of around 2,000 bottles, manual feeding can be selected; for a production of around 4,000 bottles, a semi-automatic bottle handling machine can be selected; and for a production of around 10,000 bottles, a fully automatic bottle handling machine must be selected.

Empty bottle wind conveying system

The empty bottle wind conveying system is used to transport empty bottles from the bottle handling machine to the filling machine. The empty bottle wind conveying system generally uses a wind duct and a hanging plate. The empty bottles are blown by a blower to move smoothly along the hanging plate.

Bottle filling equipment

Bottle filling equipment is used to fill water into bottles. Bottle filling equipment generally uses a conventional pressure filling method, which relies on the gravity of the liquid for filling. By adjusting the position of the return air pipe of the filling valve, a fixed liquid level filling can be achieved. When changing the bottle type, only the dial wheel guide plate needs to be replaced. The bottle is conveyed through the star wheel to the bottle, and the other parts do not need to be adjusted. According to the height of the bottle, the bottle output is slightly adjusted.

Bottle cap disinfection equipment

Bottle cap disinfection equipment is used to disinfect the bottle caps to ensure the hygiene and safety of the bottle caps. Bottle cap disinfection equipment generally uses ozone disinfection.

Finished product conveyor

The finished product conveyor is used to transport the filled bottled water to the inspection, inkjet printing, and labeling equipment. The finished product conveyor generally uses chain or belt.

Inspection equipment

Inspection equipment is used to inspect the bottled water to ensure that there are no impurities inside the bottled water. Inspection equipment generally uses ultraviolet lamps for detection.

Strong drying machine

The strong drying machine is used to dry the surface of the bottle, making it easier for inkjet printing and labeling. The strong drying machine generally uses a blower for drying.

Inkjet printing equipment

Inkjet printing equipment is used to print production dates, batch numbers, and other information on bottled water. Inkjet printing equipment generally uses ink jet printing.

Labeling equipment

Labeling equipment is used to apply labels to bottled water for identification and sales. Labeling equipment generally uses labeling machines, adhesive label machines, and hot melt glue label machines.

Packaging equipment

Packaging equipment is used to package bottled water. Packaging equipment generally uses film packaging machines and carton packaging machines.

TAG: Bottle Water Filling Machine Bottle Water Production Line Water Bottle Filling Machine

-

![5L-10L Large Bottle Drinking Water production line]() 5L-10L Large Bottle Drinking Water production line

5L-10L Large Bottle Drinking Water production line -

![Automatic Small Bottle Pure Water Filling Machine]() Automatic Small Bottle Pure Water Filling Machine

Automatic Small Bottle Pure Water Filling Machine -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![Conveyor Belt For Bottle Water Production Line]() Conveyor Belt For Bottle Water Production Line

Conveyor Belt For Bottle Water Production Line -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

![Automatic Mineral Water Bottle Filling Machine]() Automatic Mineral Water Bottle Filling Machine

Automatic Mineral Water Bottle Filling Machine -

![Automatic Water Bottle Filling Machine]() Automatic Water Bottle Filling Machine

Automatic Water Bottle Filling Machine

-

![Stainless Steel 200ml Automatic Water Bottle Filling System]() Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023

Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023 -

![Bottled Water Production Line:5-gallon]() Bottled Water Production Line:5-gallonJun , 23 /2023

Bottled Water Production Line:5-gallonJun , 23 /2023 -

![In-Depth Analysis of the Water Bottle Filling Machine Market]() In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023

In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023 -

![Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling Line]() Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023

Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023 -

![Bottle Water Filling Machines and Production Line Equipment price]() Bottle Water Filling Machines and Production Line Equipment priceNov , 21 /2023

Bottle Water Filling Machines and Production Line Equipment priceNov , 21 /2023 -

![How to Choose High-Quality Bottled Water and Beverage Production Equipment?]() How to Choose High-Quality Bottled Water and Beverage Production Equipment?Dec , 17 /2023

How to Choose High-Quality Bottled Water and Beverage Production Equipment?Dec , 17 /2023 -

![Automatic Pure Water Bottling Filling Machine for Sale, All-in-One Solution]() Automatic Pure Water Bottling Filling Machine for Sale, All-in-One SolutionJan , 08 /2024

Automatic Pure Water Bottling Filling Machine for Sale, All-in-One SolutionJan , 08 /2024 -

![Streamlining Bottled Water Production: A Comprehensive Overview]() Streamlining Bottled Water Production: A Comprehensive OverviewMar , 12 /2024

Streamlining Bottled Water Production: A Comprehensive OverviewMar , 12 /2024 -

![Operating Steps and Precautions for Small Bottle Water Filling Machine]() Operating Steps and Precautions for Small Bottle Water Filling MachineMar , 13 /2024

Operating Steps and Precautions for Small Bottle Water Filling MachineMar , 13 /2024

Home /

Home /