beverage production plant

A beverage production plant is a facility dedicated to the manufacturing and packaging of various types of beverages, including soft drinks, bottled water, fruit juices, energy drinks, alcoholic beverages, and more. These plants are equipped with specialized machinery and production lines to handle the entire beverage production process, from raw material handling to final packaging. Here are some key components and processes commonly found in a beverage production plant

- Raw Material Handling: The plant receives raw materials such as water, fruit concentrates, flavorings, sweeteners, and additives. These materials are stored in tanks and silos before being used in the production process.

- Mixing and Blending: Beverage recipes are carefully formulated by mixing and blending the raw materials in precise proportions. Mixing tanks and equipment ensure that the ingredients are thoroughly combined to achieve the desired flavor profile.

- Filtration: Filtration equipment is used to remove impurities, particles, and contaminants from the liquid mixture. This step ensures product purity and clarity.

- Pasteurization or Sterilization: Depending on the type of beverage, pasteurization or sterilization processes are employed to eliminate harmful bacteria and pathogens while preserving the product's taste and quality.

- Carbonation: For carbonated beverages like soda, carbonation equipment adds carbon dioxide (CO2) to create the characteristic fizz and bubbles.

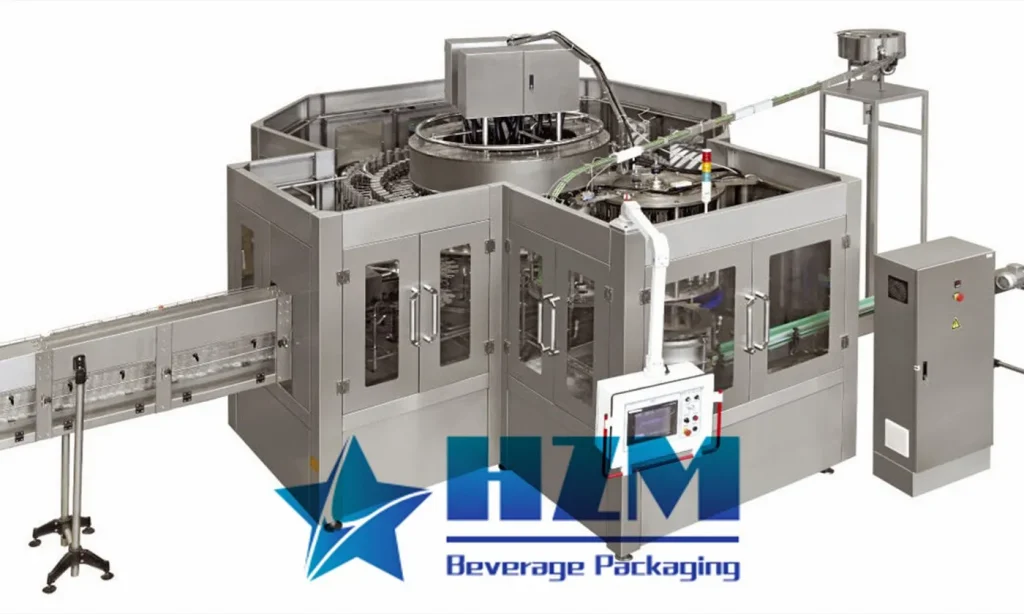

- Filling and Packaging: Filling machines and packaging lines are responsible for filling the prepared beverages into bottles, cans, or other containers. The containers are then sealed, labeled, and packaged for distribution.

- Quality Control: Quality control measures are in place throughout the production process to ensure that beverages meet safety and quality standards. This includes sensory evaluation, laboratory testing, and quality assurance procedures.

- Waste Management: Beverage production plants often have systems in place for managing waste materials generated during the production process, including recycling and disposal of by-products.

- Cleaning and Sanitation: Regular cleaning and sanitation of equipment, pipelines, and production areas are crucial to maintain hygiene and prevent contamination.

- Storage and Distribution: Finished products are stored in warehouses before being distributed to wholesalers, retailers, or directly to consumers. Temperature-controlled storage may be required for certain beverages.

Beverage production plants come in various sizes, from small-scale craft beverage facilities to large-scale factories run by multinational companies. They are designed to efficiently produce beverages while ensuring consistent taste, quality, and safety. Additionally, the choice of equipment and processes can vary depending on the specific type of beverage being produced.

TAG: Beverage Filling Machine beverage production plant Drinks Filling Machine

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine Manufacturer

Drinking water production line – Bottled Water Filling Machine Manufacturer -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer

Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling Machine

Fully Automatic Beverage Filling Machine -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

![PET Bottle CSD Beverage Filling Machine]() PET Bottle CSD Beverage Filling Machine

PET Bottle CSD Beverage Filling Machine -

![Glass Bottle CSD Beverage Filling Machine]() Glass Bottle CSD Beverage Filling Machine

Glass Bottle CSD Beverage Filling Machine -

![Soft Drinks Sparkling Water Filling Machine]() Soft Drinks Sparkling Water Filling Machine

Soft Drinks Sparkling Water Filling Machine -

![CSD Beverage Can Filling Machine]() CSD Beverage Can Filling Machine

CSD Beverage Can Filling Machine -

![Carbonated Drinks Filling Machine]() Carbonated Drinks Filling Machine

Carbonated Drinks Filling Machine

-

![Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machinery]() Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025

Automatic PET Bottle Blowing Filling Capping Machine – Best price beverage machineryOct , 24 /2025 -

![Drinking water production line – Bottled Water Filling Machine Manufacturer]() Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025

Drinking water production line – Bottled Water Filling Machine ManufacturerSep , 11 /2025 -

![Beverage Filling Line – Juice, Water, Soft Drinks, cola, Beer]() Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025

Beverage Filling Line – Juice, Water, Soft Drinks, cola, BeerJul , 21 /2025 -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling MachineDec , 21 /2023

Automatic Pure Water Bottling Filling MachineDec , 21 /2023 -

![Fully Automatic Beverage Filling Machine]() Fully Automatic Beverage Filling MachineOct , 11 /2023

Fully Automatic Beverage Filling MachineOct , 11 /2023 -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling MachineOct , 10 /2023

3-In-1 Water Bottle Filling MachineOct , 10 /2023 -

![Important Questions To Consider Before Purchasing Carbonated Filling Machine]() Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023

Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023 -

![Classification of beverage filling machines]() Classification of beverage filling machinesMar , 24 /2023

Classification of beverage filling machinesMar , 24 /2023 -

![Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling Machine]() Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023

Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023 -

![Application of Juice Beverage Filling Machine in the Industry]() Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023

Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023 -

![Mineral Water / Soft Drink PET Bottle Machine Production Equipment]() Mineral Water / Soft Drink PET Bottle Machine Production EquipmentJun , 06 /2023

Mineral Water / Soft Drink PET Bottle Machine Production EquipmentJun , 06 /2023 -

![Carbonated drinks Filling Machine: A Comprehensive Solution]() Carbonated drinks Filling Machine: A Comprehensive SolutionJul , 18 /2023

Carbonated drinks Filling Machine: A Comprehensive SolutionJul , 18 /2023 -

![Beverage Filling Machine: Vital Equipment on the Beverage Production Line]() Beverage Filling Machine: Vital Equipment on the Beverage Production LineAug , 24 /2023

Beverage Filling Machine: Vital Equipment on the Beverage Production LineAug , 24 /2023 -

![How to Choose the Right Filling Machine?]() How to Choose the Right Filling Machine?Aug , 28 /2023

How to Choose the Right Filling Machine?Aug , 28 /2023